Continuous laminating type aerobic fermentation system and using method thereof

An aerobic fermentation, continuous technology, used in applications, agriculture, fertilization devices, etc., can solve problems such as high moisture content, inability to move materials, and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

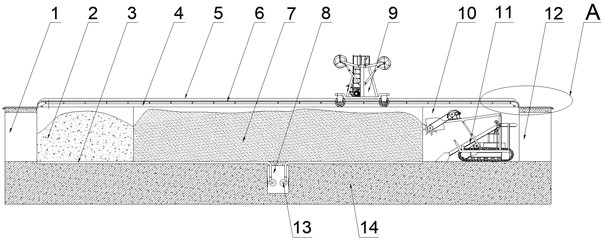

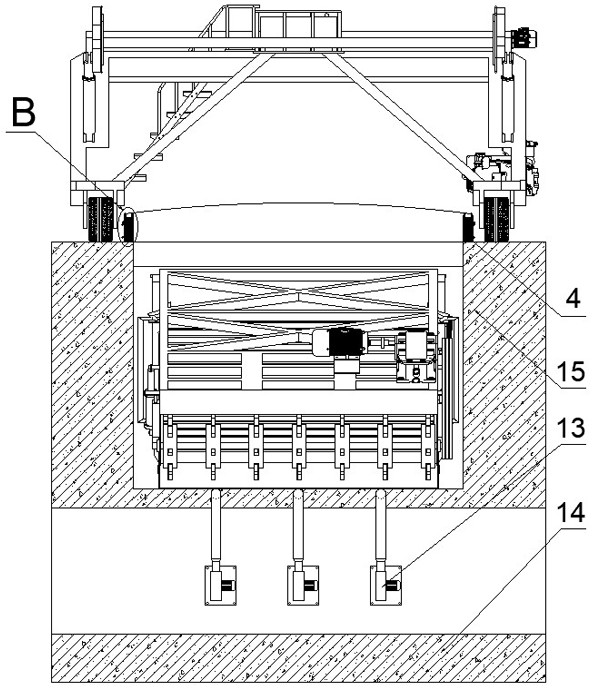

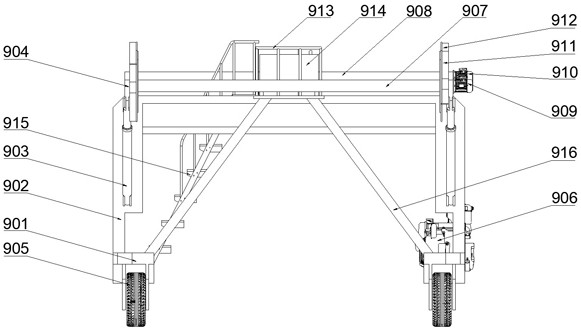

[0058] Such as figure 1 and figure 2 As shown, the continuous film-covered aerobic fermentation system provided by the present invention includes: a fermentation tank, a tank structure surrounded by an underground tank wall 15, an above-ground tank wall 4 and a tank bottom 14, two above-ground tank walls 4 are respectively fixed on the top of the two underground tank walls 15, the thickness of the above ground tank wall 4 is much smaller than the thickness of the underground tank wall 15, and the inner side wall of the above ground tank wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com