Glass fiber impregnating agent for glass fiber reinforced plastic pipeline and preparation method and device

A technology for glass fibers and preparation devices, which are used in transportation and packaging, chemical instruments and methods, mixers with rotary stirring devices, etc., to achieve increased wear resistance and flexibility, good bonding performance, and increased short-term failure pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 A kind of glass fiber sizing agent for FRP pipeline

[0048] This embodiment discloses a glass fiber sizing agent for FRP pipelines, the sizing agent includes coupling agent, lubricant A, lubricant B, film forming agent, antistatic agent, pH regulator and water, the coupling agent The agent is an enhanced silane coupling agent; the lubricant is a mixture of lubricant A and lubricant B, lubricant A is a polyoxyethylene ether lubricant, and lubricant B is a quaternary ammonium salt lubricant. The film agent is a mixture of two different types of epoxy emulsions, film forming agent A and film forming agent B, the antistatic agent is an ammonium salt antistatic agent, and the pH regulator is an organic acid with a pH of 2.5-6; The percentage of the solid mass of each component in the sizing agent to the solid mass of the sizing agent is expressed as follows:

[0049]

[0050]

[0051] The solid mass of the wetting agent accounts for 3.5-7.5% of the total...

Embodiment 2

[0055] Embodiment 2 A kind of glass fiber sizing agent preparation device for FRP pipeline

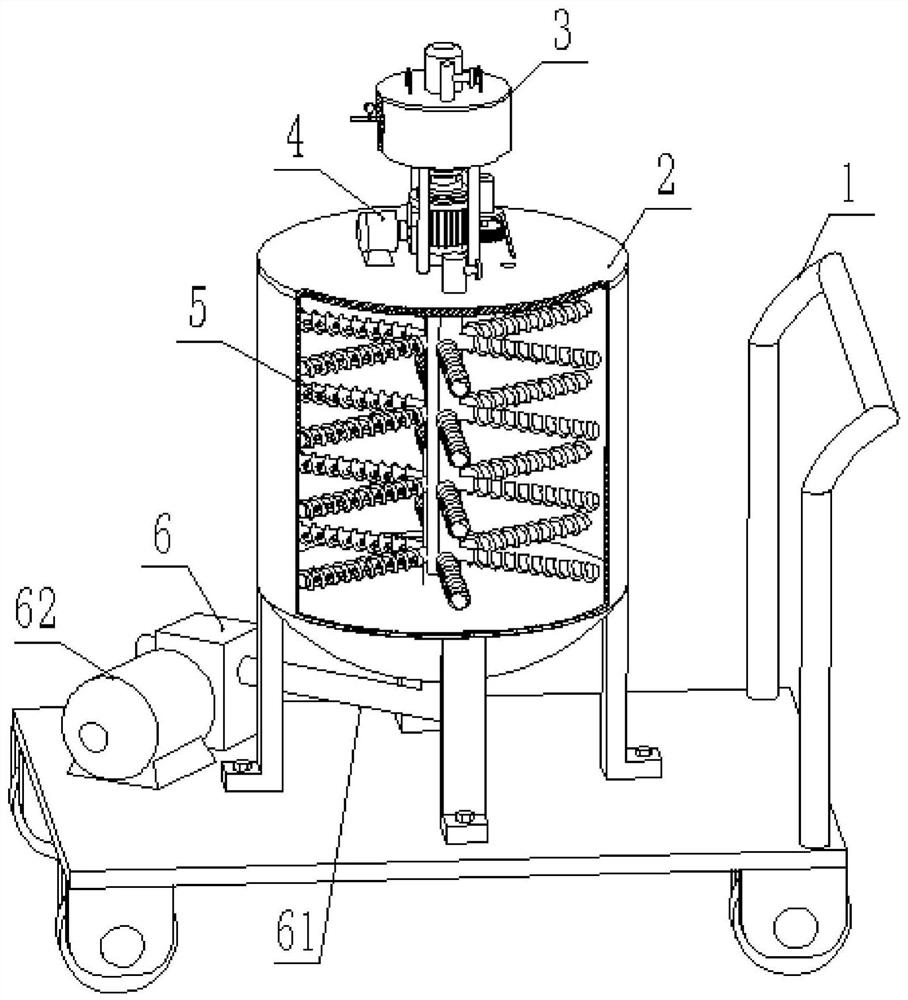

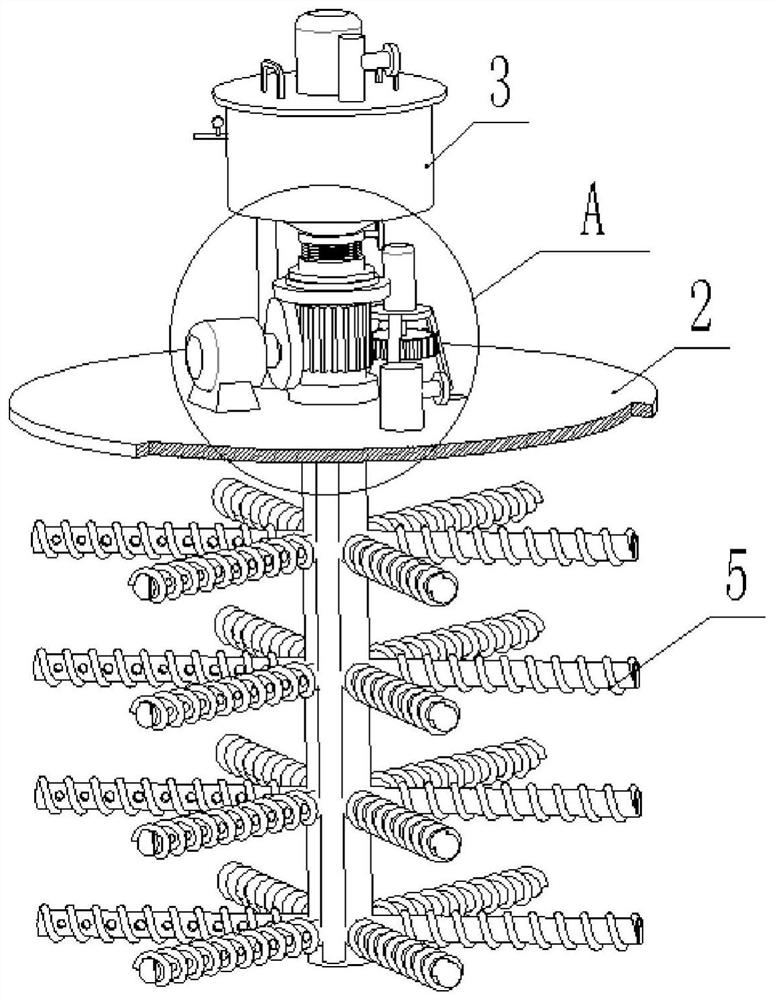

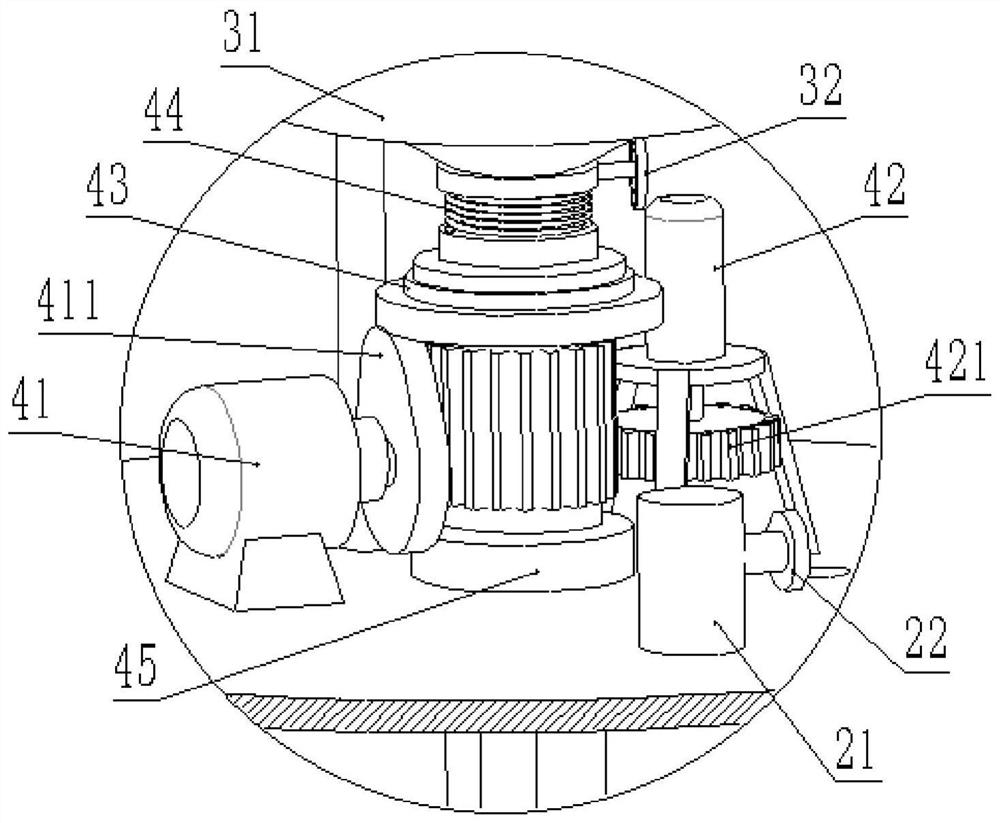

[0056] This embodiment discloses a device for preparing a glass fiber sizing agent for FRP pipes, such as figure 1 As shown, the main tank body 2 is included, the main tank body 2 is provided with a main stirring mechanism 5, the top of the main tank body 2 is provided with a main driving mechanism 4 for making the main stirring mechanism 5 carry out material stirring, and the top of the main tank body 2 is provided with Feed pipe, the bottom end is provided with discharge pipe 61, described main stirring mechanism 5 comprises main stirring shaft 51, is radially provided with several heating stirring bodies 52 on the main stirring shaft 51, and main driving mechanism 4 includes for making main The agitator shaft 51 is a lifting drive part for reciprocating up and down and a rotary drive part for rotating the main agitator shaft 51 , and the lift drive part and the rotary drive part are...

Embodiment 3

[0068] Embodiment 3 A kind of preparation method of glass fiber sizing agent for FRP pipeline

[0069] This embodiment discloses a method for preparing a glass fiber sizing agent for FRP pipelines, comprising the following steps:

[0070] Step A According to the ratio, add a total of 40-50% of pure water into the main tank through the feed pipe, then add a total of 1-5% of the pH regulator, turn on the main stirring mechanism to stir evenly, and the stirring time is 3 -5min, the stirring speed is 15r / min;

[0071] Step B: Add the required amount of polyamide-based silane coupling agent into the main tank through the feeding pipe according to the speed of 0.3kg / min and stir evenly. The stirring time is 20-40min. Test the pH of the mixed liquid and control its pH 3-4.5;

[0072] Step C: Put the required amount of lubricant and antistatic agent into the auxiliary tank with pure water at 60-70 degrees Celsius through the auxiliary feeding pipe for material premixing, start the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com