Unmanned aerial vehicle rocket booster

A technology of boosters and aircraft rockets, which is applied in the field of solid rocket motors, and can solve the problems of unstable thrust deflection of boosters and thrust rods, difficulty in realizing threaded connections, and easy to be affected by human operations, so as to improve the connection impact. The effect of low force, small mass, and reduced assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

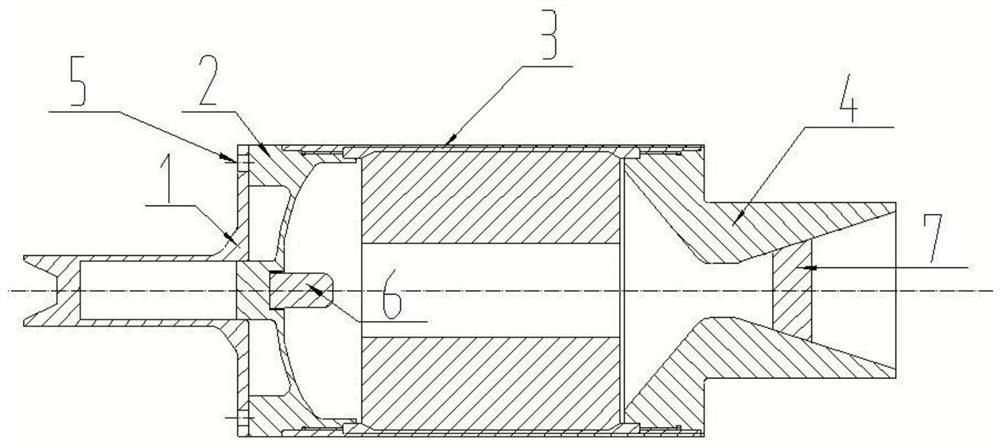

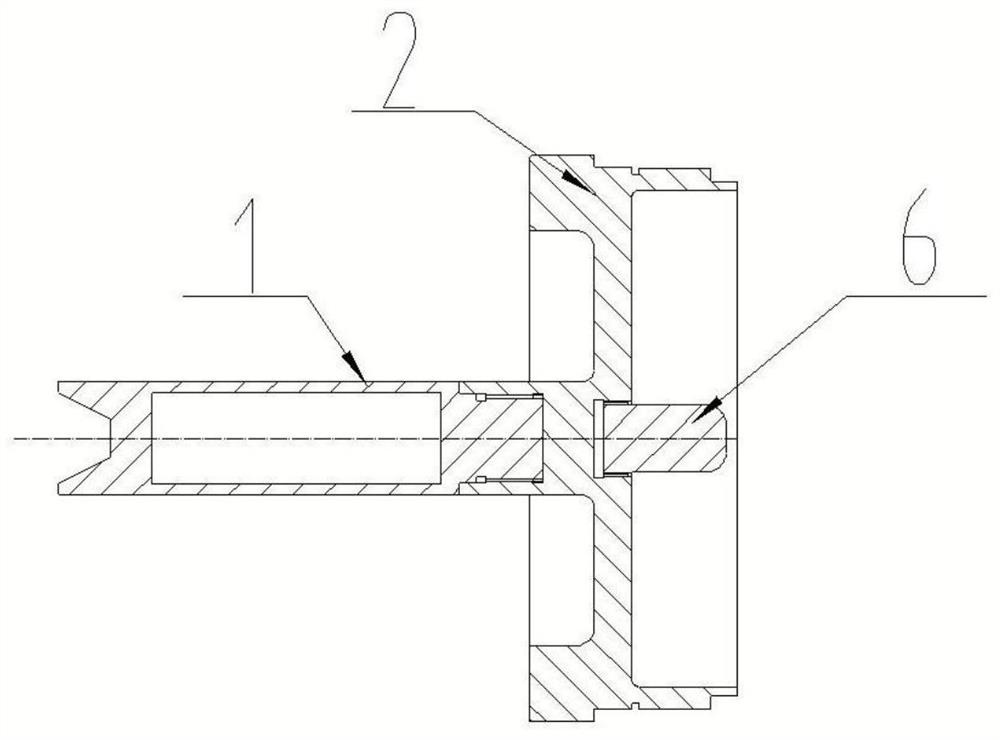

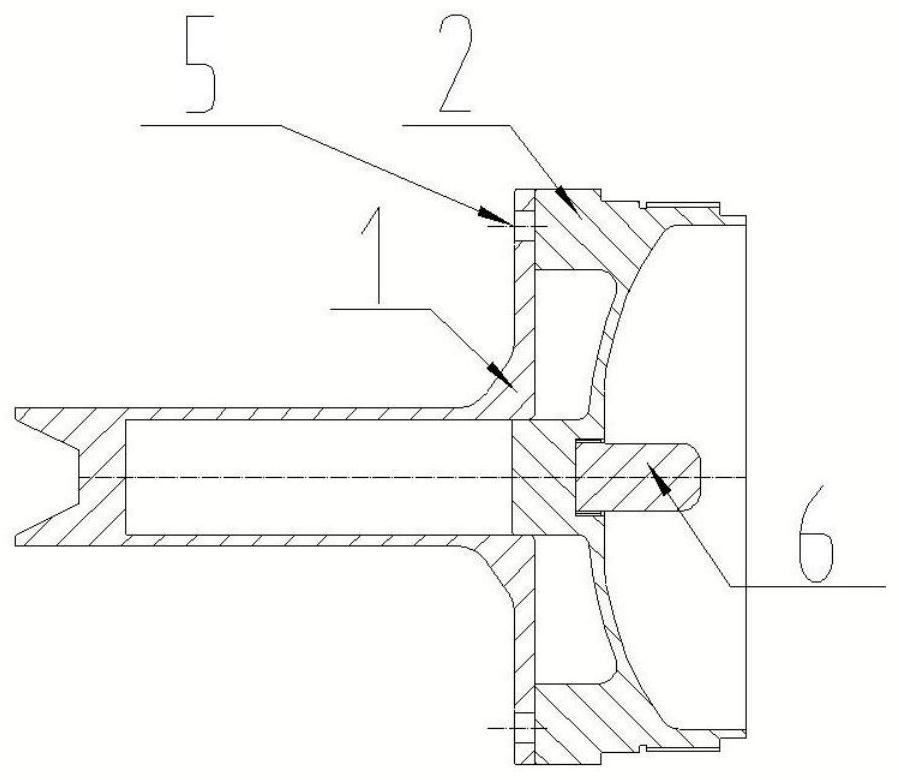

[0033] This embodiment is a model drone rocket booth, including thrust rod 1, front top cover 2, combustion chamber 3, nozzle, screw 5, igniter 6, and clogging 7. Wherein, the front top cover 2 is located at the front end of the combustion chamber 3; the center positioning sleeve 8 of the pushing rod is set on the positioning boss at the center of the front top cover, and the end surface of the front end cover and the thrust rod. The end face of the flange plate. The igniter 6 is located within a chamber formed between the front end surface of the front top cover and the front end surface of the combustion chamber, and one end of the igniter is located in the threaded blind hole of the inner end surface of the front cover; the ignition The server 6 is the prior art. The nozzle 4 and the clogging 7 are all prior art and assembled according to conventional methods, and the segments of the nozzle are mounted in the rear end of the combustion chamber by thread; blockage 7 is mounted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com