Construction method for replacing knuckle bearing and pin shaft on inner side of crank on ladle turret

A technology of joint bearing and construction method, which is applied in the direction of manufacturing tools, metal processing equipment, casting molten material containers, etc., can solve the problems of long construction time, high construction cost, and large space occupation, so as to shorten construction time, reduce production and cost. Construction cost and the effect of saving construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

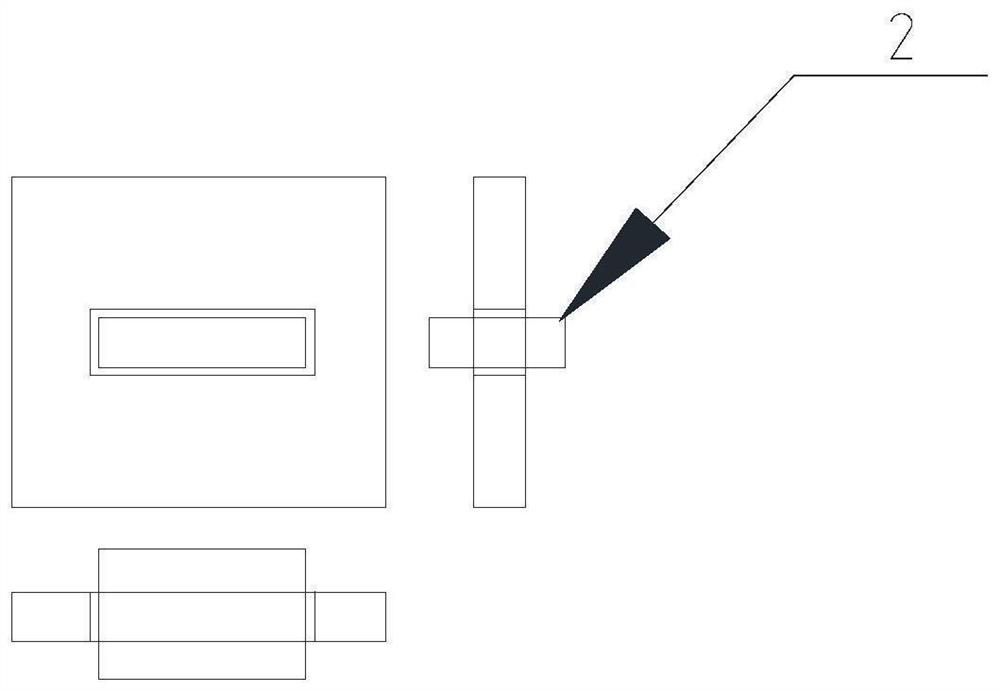

[0046] Shougang Qian'an Iron and Steel Co., Ltd. Steelmaking Operation Department No. 1 steelmaking operation area 1# slab continuous casting machine ladle rotary table has been used in normal working environment for nearly 11 years. Now it is found that 1# ladle rotary table 2# The inner joint bearing on the right side of the upper crank (also known as L arm) makes abnormal noise when lifting and lowering while sitting on the heavy steel ladle. After analysis, the direct cause of the abnormal sound is the inner joint bearing or pin on the right side of the upper crank of the 2# fork arm. The shaft has been worn out, and the rough contact surface formed by the worn joint bearing or the pin shaft of the 2# yoke when the ladle is lifted and lowered by the load produces abnormal noise when it makes relative motion. In order to prevent further expansion of the situation and possible serious consequences to production in the future, a steelmaking operation area requested that the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com