Method for automated electronic control of brake system in utility vehicle having Anti-lock braking protection

An electronic control and braking system technology, applied in the field of pneumatic braking systems and vehicles, can solve problems such as redundancy, and achieve the effects of improving stability, preventing axle locking and preventing locking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

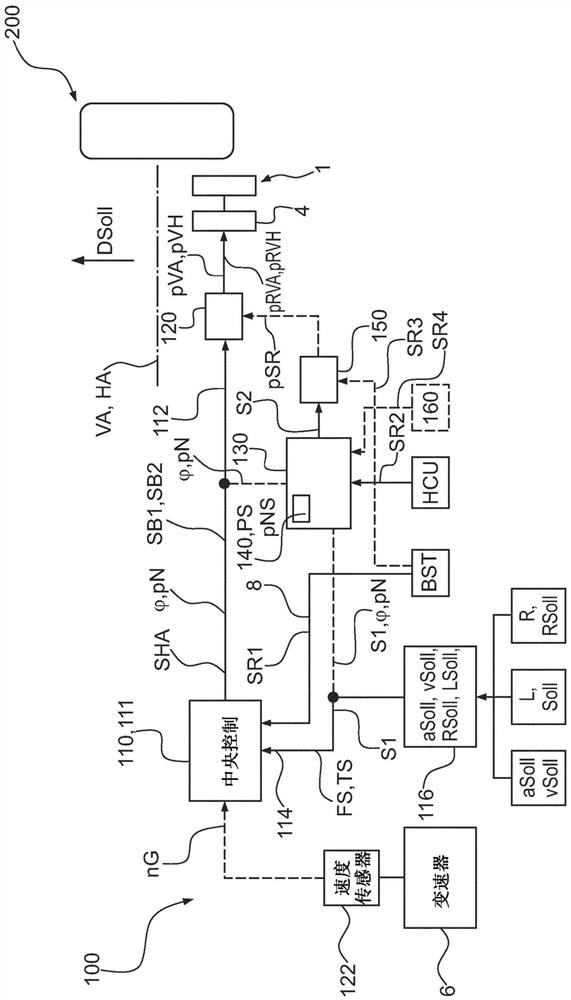

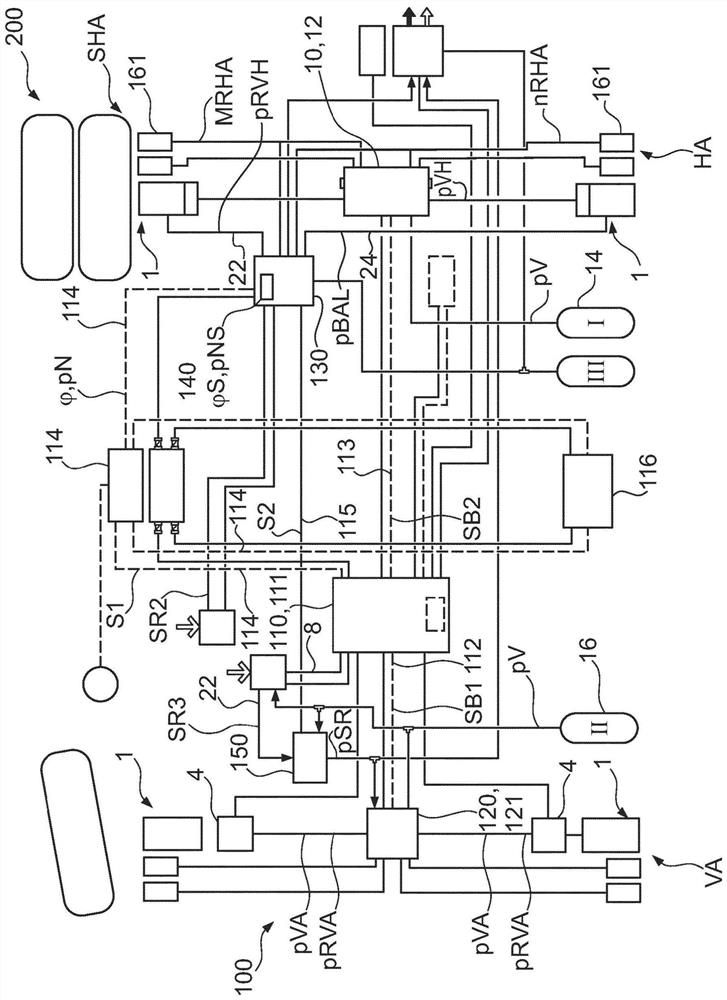

[0049] in accordance with figure 1 In the embodiment of FIG. 1 , a portion of the braking system 100 of a vehicle 200 is shown in a block diagram. Brake system 100 therefore has a first electronic control unit 110 and a first electropneumatic control device 120 . In this exemplary embodiment, the first electronic control unit 110 is designed as a so-called central module 111 and is connected via a first bus 112 to a first electropneumatic control device 120 . First electronic control unit 110 supplies at least one first brake pressure signal SB1 , but preferably also a second brake pressure signal SB2 , via first bus 112 to first electropneumatic control device 120 . The first electropneumatic control device 120 preferably has an electronic control unit (not shown) and one or more valves (not shown), which are used to convert the first brake pressure signal SB1 and preferably the second brake pressure signal SB1 Dynamic pressure signal SB2 is converted into at least front ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com