Electric on-off test method for double-sided substrate

A double-sided substrate, on-off test technology, used in semiconductor/solid-state device testing/measurement, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

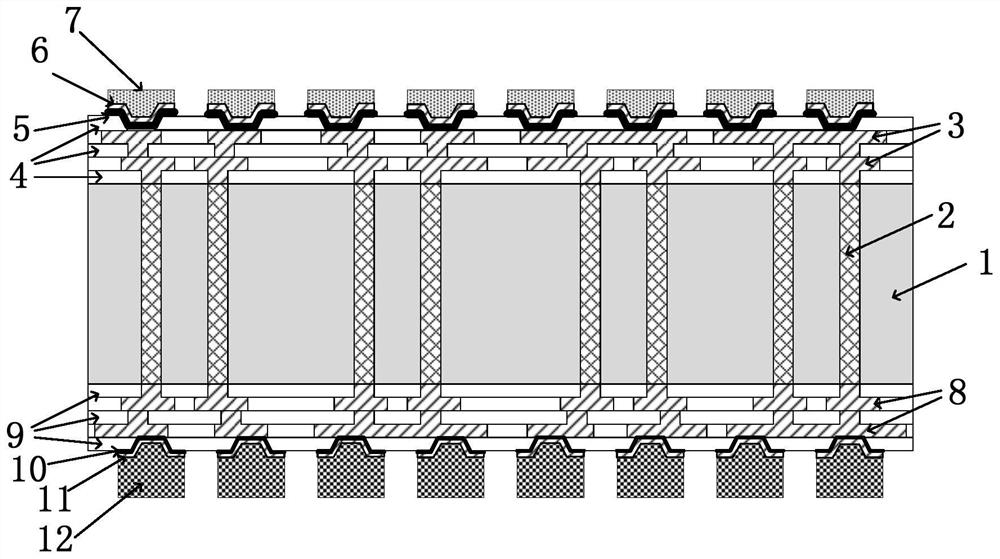

[0034] Such as figure 1 As shown, the TSV conductive via 2 penetrating the silicon substrate 1 realizes the electrical connection between the upper and lower surfaces of the silicon substrate 1 . The front metal wiring 3 is arranged for horizontal electrical connection on the upper surface of the silicon substrate 1. The number of layers of the front metal wiring 3 is at least one layer. When the front metal wiring 3 is multi-layered, the front metal wiring 3 of each layer passes through the front The inter-metal dielectric 4 is electrically insulated, and the electrical connection between the front metal wirings 3 of each layer is realized through the connection holes between each layer. The front bumps 7 are electrically connected to the front metal wiring 3 through the front under bump metallurgy (UBM) 6 . Correspondingly, the back metal wiring 8 is arranged for horizontal electrical connection on the lower surface of the silicon substrate 1, and the number of layers of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com