Method for quickly and automatically sampling continuous casting tundish

A continuous casting tundish and automatic sampling technology, applied in the field of metallurgical steelmaking and continuous casting, can solve the problems of sampling stability, success rate and poor sample quality, reduce high-temperature radiation and splash burns and scald accidents, and is beneficial to Analyze, ensure sampling accuracy and the effect of sampling time node control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

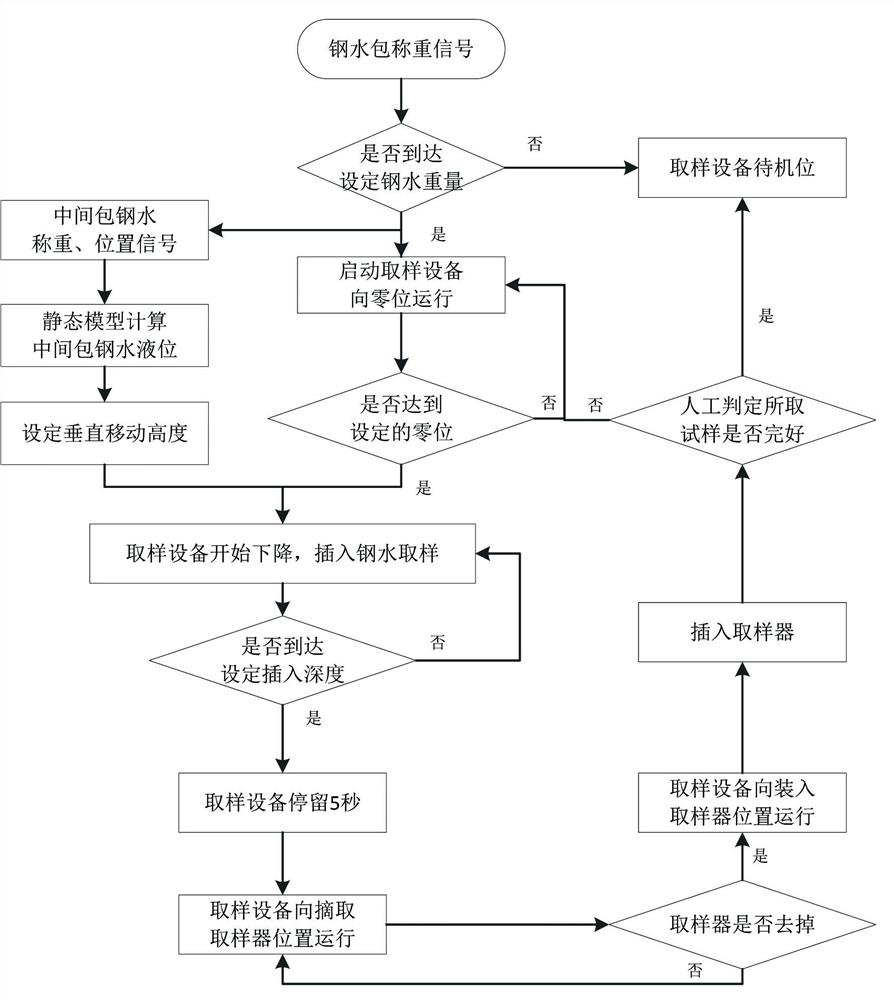

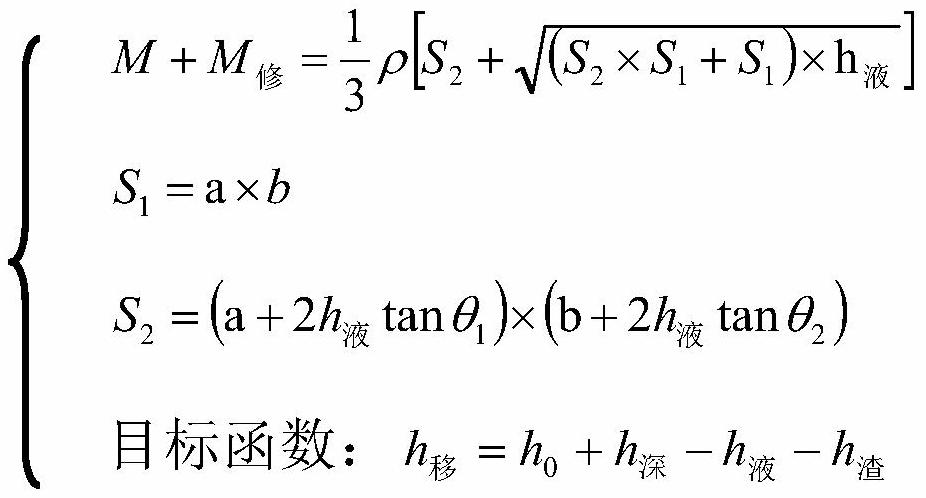

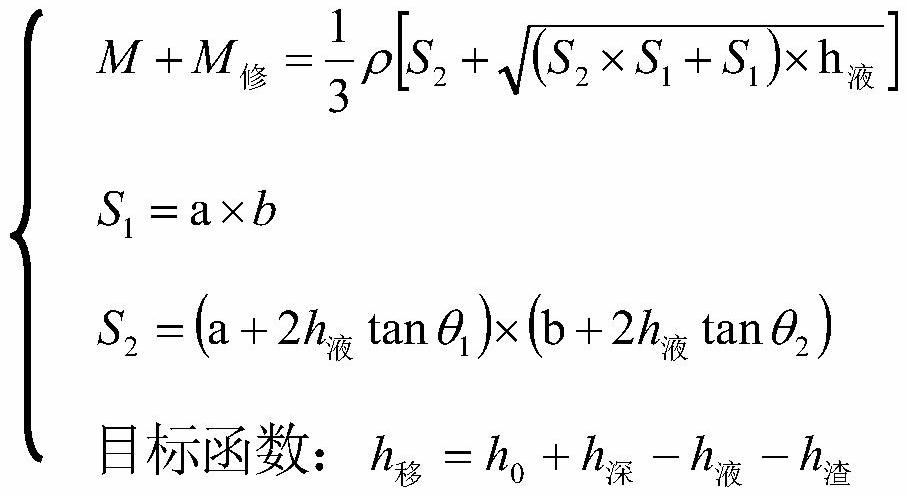

[0026] The present invention sets the technical requirements according to the tundish molten steel sampling process, and determines the collection and sampling points of the molten steel tank at different tonnages of molten steel; the molten steel tank at different tonnages of molten steel can be confirmed by the weighing signal of the molten steel tank; at this time, the molten steel tank The weighing signal is transmitted to a special sampling device, and the corresponding sampling device will automatically start the sampling operation after receiving the confirmed signal. At the same time, the weighing and position signals of the continuous casting tundish are transmitted to the static model of the tundish liquid level to calculate the liquid steel level of the tundish, so as to determine the vertical movement height of the sampler from the zero position; at this time, the sampler is moved from the zero position The vertical movement height signal is transmitted to the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com