Liquid spraying device for bore maintenance and maintenance system

A technology of a liquid spray device and a maintenance system, which is applied in the field of gun bore maintenance, can solve the problems of small-caliber gun bore cleaning and low maintenance quality, and achieves the effects of small footprint, convenient processing and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

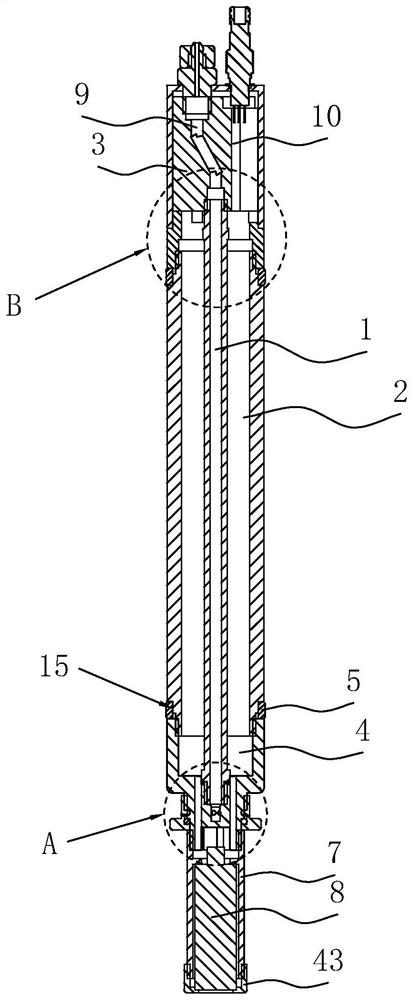

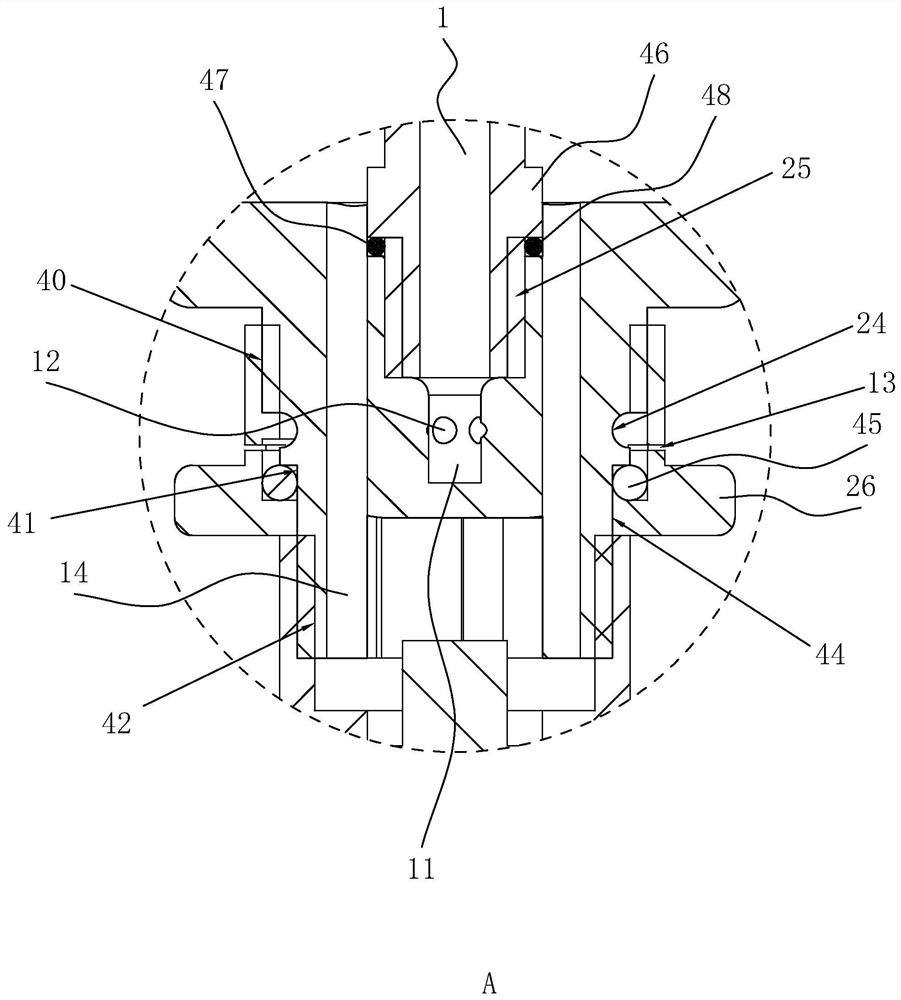

[0041] The following is attached Figure 1-6 The application is described in further detail.

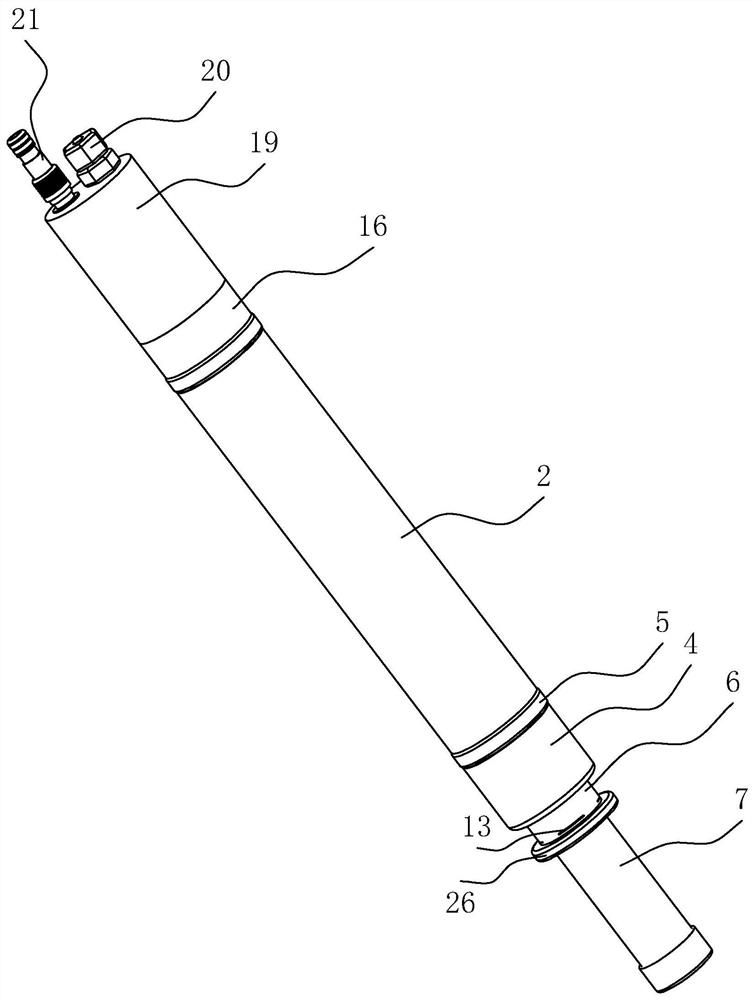

[0042] The embodiment of the present application discloses a liquid spraying device for gun bore maintenance. refer to figure 1 and figure 2 The liquid injection device for gun bore maintenance includes a coaxially arranged guide tube 1 and an extension tube 2, one end of the guide tube 1 is detachably sealed and connected to an adapter 3, the other end is detachably sealed and connected to a nozzle 4, and one end of the extension tube 2 is connected to the The adapter 3 is detachably connected, and the other end is detachably connected to the nozzle 4. Both ends of the extension tube 2 protrude along its radial direction and are provided with a positioning ring 5 adapted to the inner diameter of the gun bore. The positioning ring 5 is made of PTFE, PE, PVC, etc. Polymer plastic is made, and positioning ring 5 is made by PTFE in the present implementation.

[0043] refer to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com