Fresh air dehumidification drying system for hydropower station gallery and control method of fresh air dehumidification drying system

A new air dehumidification and drying system technology, applied in heating and ventilation control systems, heating and ventilation safety systems, air conditioning systems, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

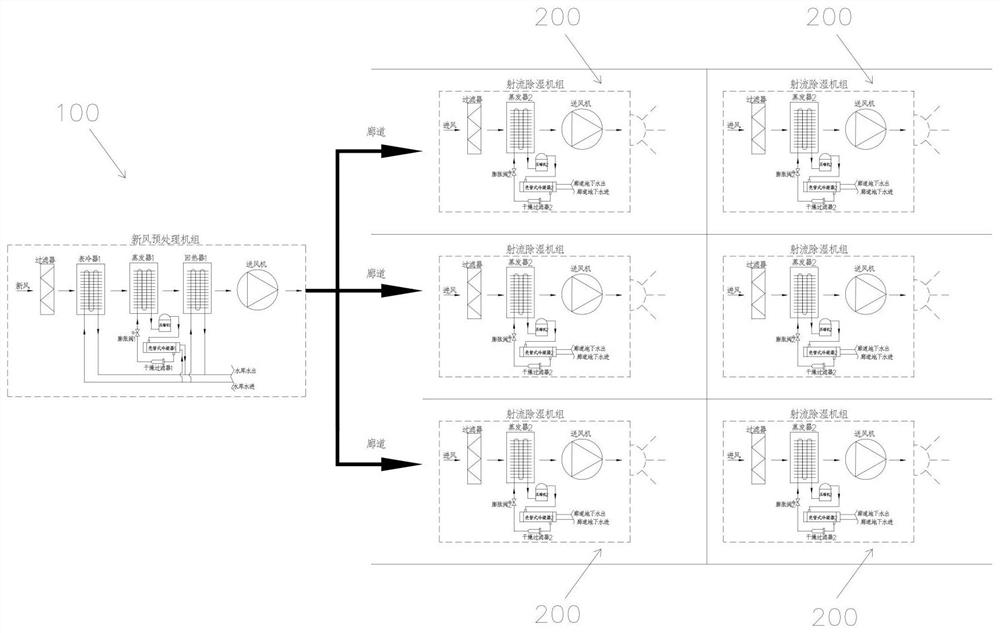

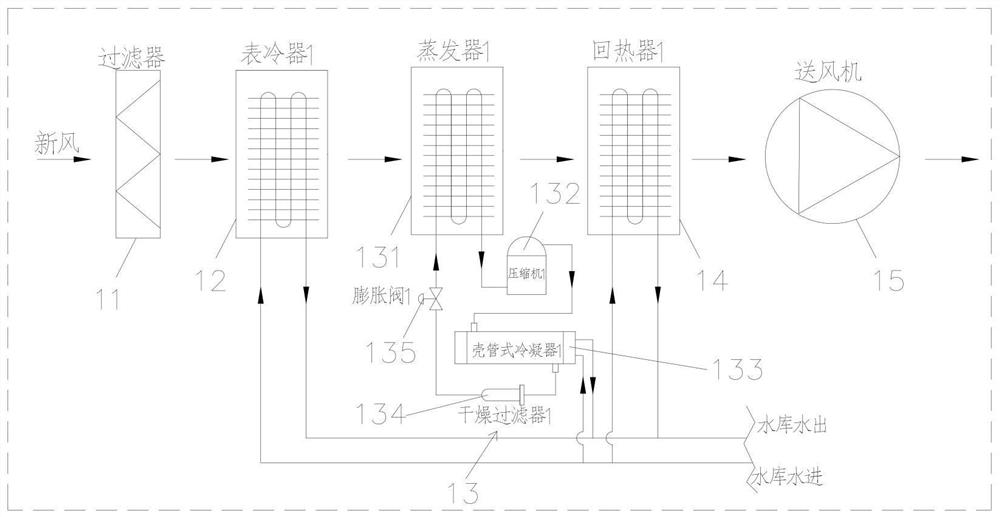

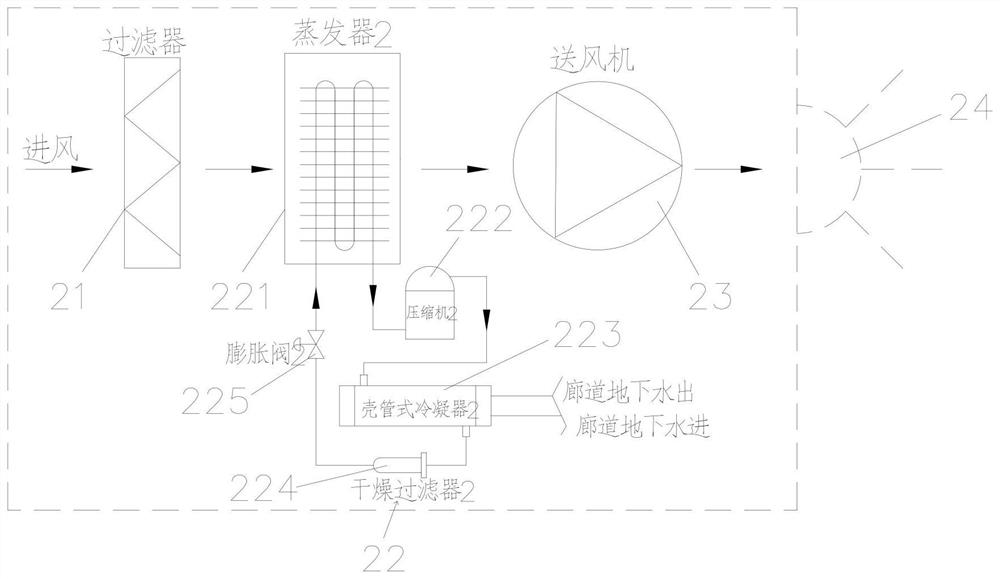

[0055] Please refer to the attached Figure 1-3 As shown, the embodiment of the present invention discloses a fresh air dehumidification and drying system for a gallery of a hydropower station. The gallery of the hydropower station includes a main gallery and a number of sub-galleries, and the sub-galleries and the main gallery are arranged vertically and horizontally. The system includes a fresh air pretreatment unit 100 and a jet dehumidification unit 200. The fresh air pretreatment unit 100 is arranged at the air intake of the main gallery, and the jet dehumidification unit 200 is arranged in each sub gallery. The pretreatment unit 100 includes a first filter 11, a surface cooler 12, a first refrigeration system 13, a regenerator 14 and a first blower 15. The fresh air pretreatment unit 100 inhales fresh air from the air intake and passes through the first After the filter 11, the surface cooler 12, the first refrigeration system 13 and the regenerator 14, they are sent int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com