Double-fireproof cover, air window furnace end, double-display panel and blast gas stove

A technology for gas stoves and burners, which is applied to household stoves/stoves, stoves/stove bases, burners, etc., and can solve problems such as low safety margins, flame separation/flame removal from the burner, and obstacles to the suction of the ejector tube, etc., to achieve The effect of increasing the primary air coefficient, increasing the firepower adjustment ratio, and reducing the gas flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

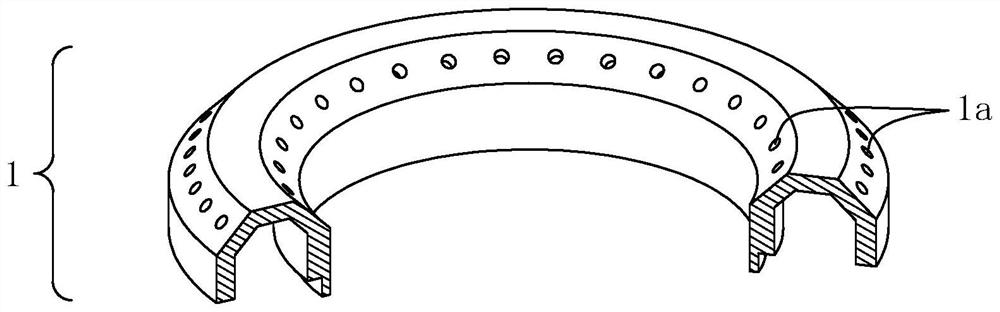

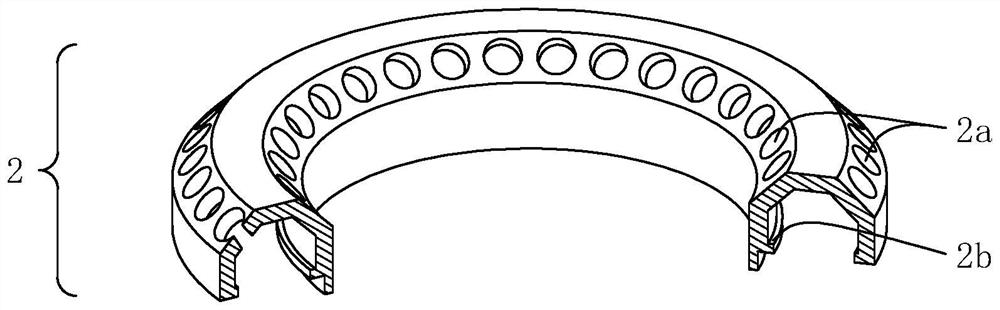

[0176] Embodiment 1: Round hole double anti-outer ring fire cover 5, see figure 1 ~5.

[0177] figure 1 For the existing conventional round hole outer ring fire cover 1, its conventional round hole burner 1a can not be too large, it will backfire if it is big, and it can not be too small, it will leave the flame if it is small. A fire hole is in a dilemma. It can only find a balance in a small range in the middle. The margin of safety is not large. There is almost no room for further improvement of the combustion situation.

[0178] The present embodiment round hole double anti-outer ring fire cover 5 (the described double anti-tempering, anti-flaming, hereinafter the same), is made of cover body 2, flame retardant 3, retaining ring 4. The cover body 2 of this fire cover 5 is to change the conventional round hole burner 1a of the existing burner 1 into the anti-flame large burner 2a of a large cross section without considering the tempering restriction, and then install it...

Embodiment 2

[0182] Embodiment 2: Slit double anti-outer ring fire cover 10, see Figure 6~1 0.

[0183] Image 6 It is the existing slit outer ring fire cover 6, and its conventional slit burner 6a is limited by the conditions of tempering and flame separation, so it cannot be too large or too small, and the size limit is basically locked. If you want to greatly improve the combustion situation, it is almost gone. space.

[0184] This slit double anti-outer ring fire cover 10 is made of cover body 7, flame retardant part 8, retaining ring 9. This fire cover cover body 7 is that the conventional slit burner 6a of the existing outer ring fire cover 6 can be changed into the anti-flame large burner 7a of large cross-section without considering the tempering restriction.

[0185]The flame retardant part 8 of the fire cover adopts a number of stainless steel wire knitted mesh tubes to be nested into strips, which are properly pressurized and filled in the cover body 7 to approach the fire p...

Embodiment 3

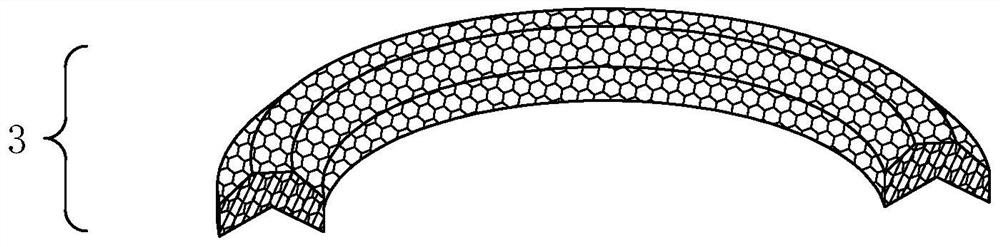

[0189] Embodiment 3: The double anti-outer ring fire cover 13 of the honeycomb panel with the top opening, see Figure 11-1 3.

[0190] The fire cover 13 is made of a cover body 11 and a fire retardant 12 . The cover body 11 is composed of an inner side wall 11a, an outer side wall 11b, and a connecting strip 11c between the inner and outer walls, and the cover body 11 is an annular groove transparent up and down. The flame retardant 12 adopts the unique honeycomb ceramic plate / honeycomb metal plate of the infrared burner. The flame retardant 12 is embedded in the annular groove of the cover body 11, and the top is exposed as the combustion level of the honeycomb burner. The fire cover has the following characteristics.

[0191] 1. Although the fire cover adopts the honeycomb ceramic plate (or porous ceramic plate, the same below) unique to infrared combustion, it does not work in the full premixed infrared combustion working condition. Its structure is mainly designed acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com