High-reliability intelligent rotary actuator

A technology for actuators and electromagnetic clutches, applied in clutches, mechanical energy control, components with teeth, etc., can solve the problems of complex assembly process of rotary actuators, insufficient lubrication of gear sets, low production efficiency, etc., and solve the problems of alternating temperature The environment is stuck, the complex assembly process is solved, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

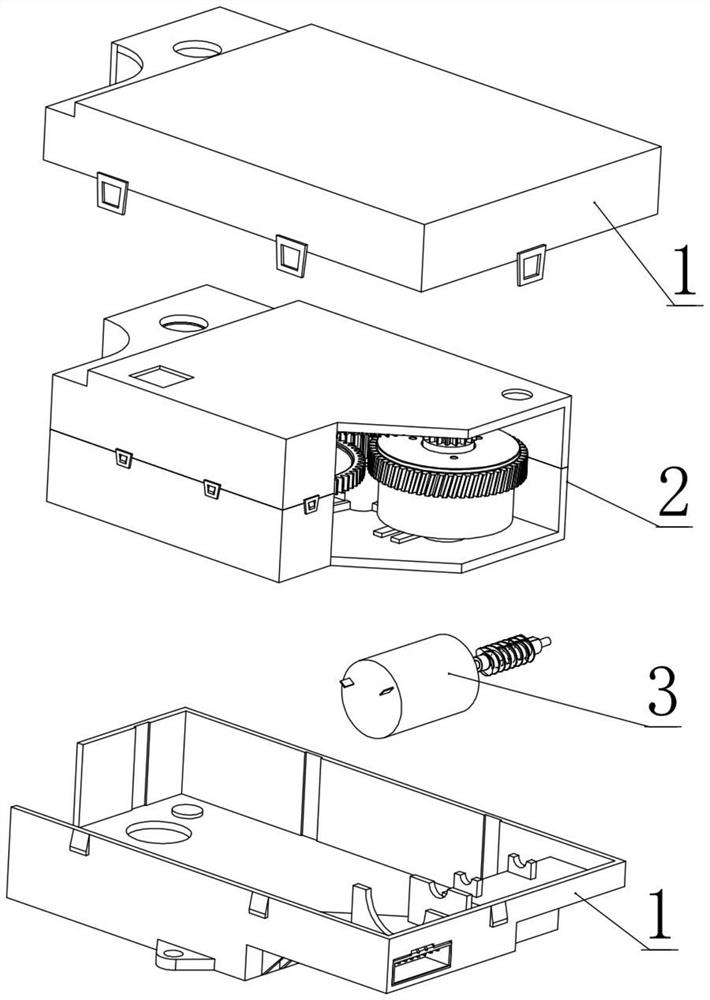

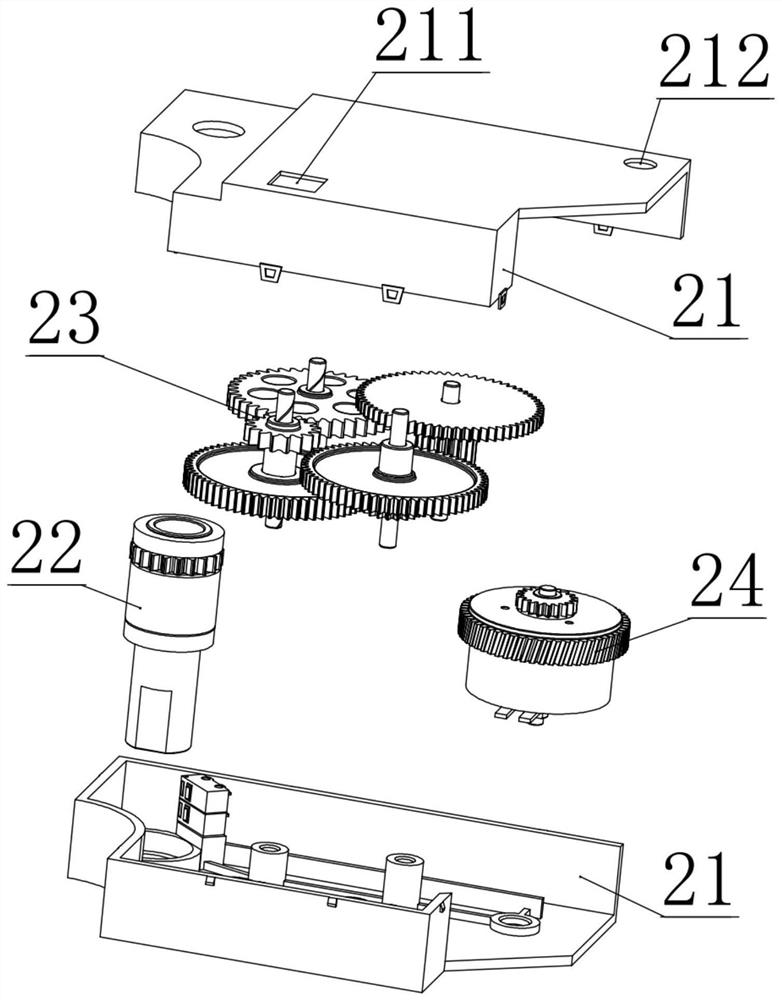

[0026] A rotary actuator such as Figures 1 to 8 As shown, it includes a casing 1, a transmission box 2, and a power source 3; the transmission box 2 includes a box shell 21, an output shaft 22, a reduction gear set 23, and a clutch assembly 24; 23 and the clutch assembly 24 are assembled in the casing 21; the casing 21 and the power source are assembled in the casing 1; the power source 3 drives the clutch assembly 24, the clutch assembly 24 drives the reduction gear set 23, and the reduction gear set 23 drives the output shaft 22 to rotate .

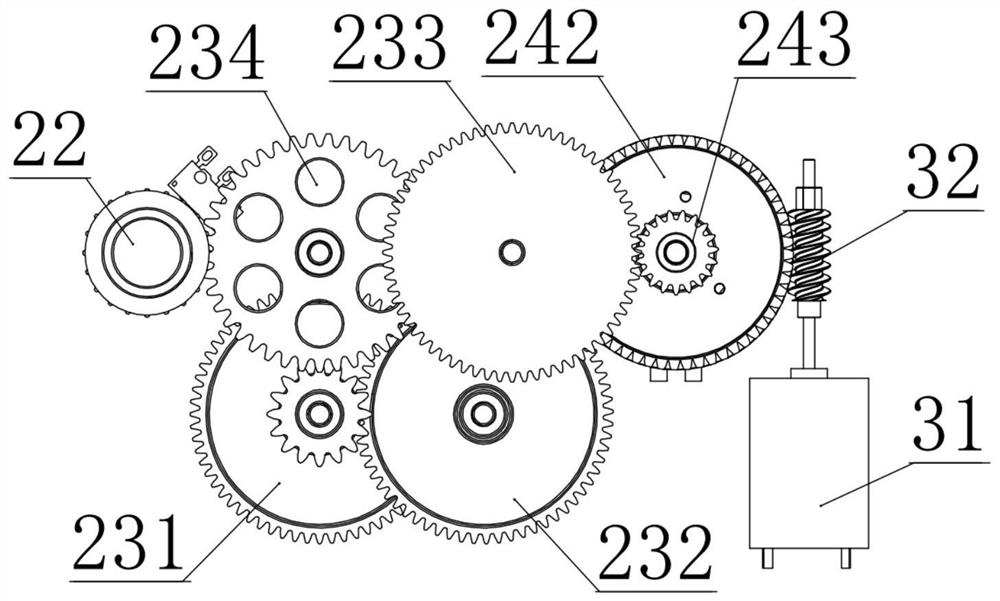

[0027] In this embodiment, two oil injection ports are provided on the surface of the tank shell 21 , the first oil injection port 211 is facing the reduction gear set 23 , and the second oil injection port 212 is facing the clutch assembly 24 . The reduction gear set 23 includes a first dual gear 231, a second dual gear 232, a third dual gear 233, and a transition gear 234; the transition gear 234 meshes with the ring gear on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com