Stainless steel storage tank rolling assembly horizontal construction device and construction method

A technology of construction device and rolling group, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of low safety guarantee, slow progress, low precision, etc., and achieve the construction cost reduction, small impact and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

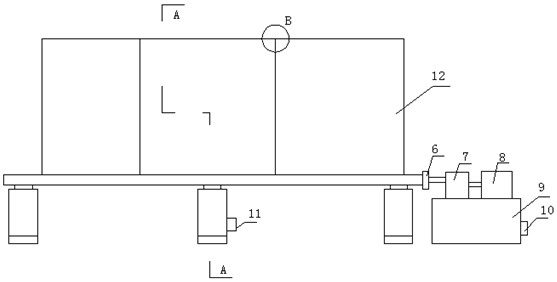

[0027] A stainless steel storage tank rolling assembly horizontal construction device, which consists of: a horizontal assembly device structure, a driving device, a stability monitoring device and an anti-carburization structure. The horizontal assembly device includes a tugboat box base square Pipe 1, the square tube at the base of the tugboat box and the support tugboat box 2 are welded and fixed, and the support tugboat box is connected with the support tugboat 3 through a rotating shaft. There are rubber or binding brown ropes 5, and one end of the trusteeship is equipped with a steel pipe connection plate 6, the steel pipe connection plate is connected with the reducer 7, the reducer is connected with the motor 8, and the motor is fixed above the base 9. An electrical control box 10 is installed on one side of the base. The main work of the electrical control box is power transmission and power failure to realize start-up and parking. Through the trusteeship, one side is ...

Embodiment 2

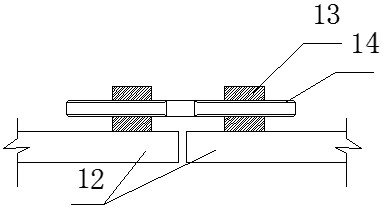

[0029] According to the stainless steel storage tank rolling group-to-horizontal construction device described in Embodiment 1, after the tank body 12 is hoisted in sections on the trusteeship, a fixing screw with threaded holes is welded on the tank wall near the tank mouth inside the tank body. Block 13, the fixed block is screwed with a pull bolt 14, under the fastening of the pull bolt and the fixed block, the tank body is closed, and the staggered mouth of the tank body adopts a slope fixed block welded inside the tank body close to the tank mouth 15. A top screw 16 is screwed into the slope fixing block, and the displacement is formed by fastening and releasing the slope fixing block and the top wire with bolts. Among them, the pull bolt and the fixing block are a group, and the slope fixing block and the jacking wire are a group with a distance of 250mm-300mm. It mainly depends on the size of the misalignment. How much is that the perimeter of the tank is evenly distrib...

Embodiment 3

[0031] According to the stainless steel storage tank rolling group pair horizontal construction device described in embodiment 1 or 2, the square tube at the base of the tugboat box, the support tugboat box, the support tugboat and the trusteeship form a horizontal group For the device structure, the steel pipe connection plate, the reducer, the motor and the base form the driving device, the infrared generator forms the stability monitoring device, and the vulcanized Rubber or binding brown rope to form an anti-carburization structure. Among them, the rubber is vulcanized on-site to the hosting. When the stainless steel tank is placed on the device, the carbon steel device and the stainless steel will not have carburizing reaction due to the isolation of the rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com