Industrial-grade aluminum oxide continuous fiber thousand-hole spinning channel and bundling device

A technology of continuous fiber and spinning tunnel, which is applied in the field of industrial-grade alumina continuous fiber thousand-hole spinning tunnel and clustering device, which can solve the problems of floating and broken filaments, reduce broken ends and increase cohesion , reducing the effect of mutual entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

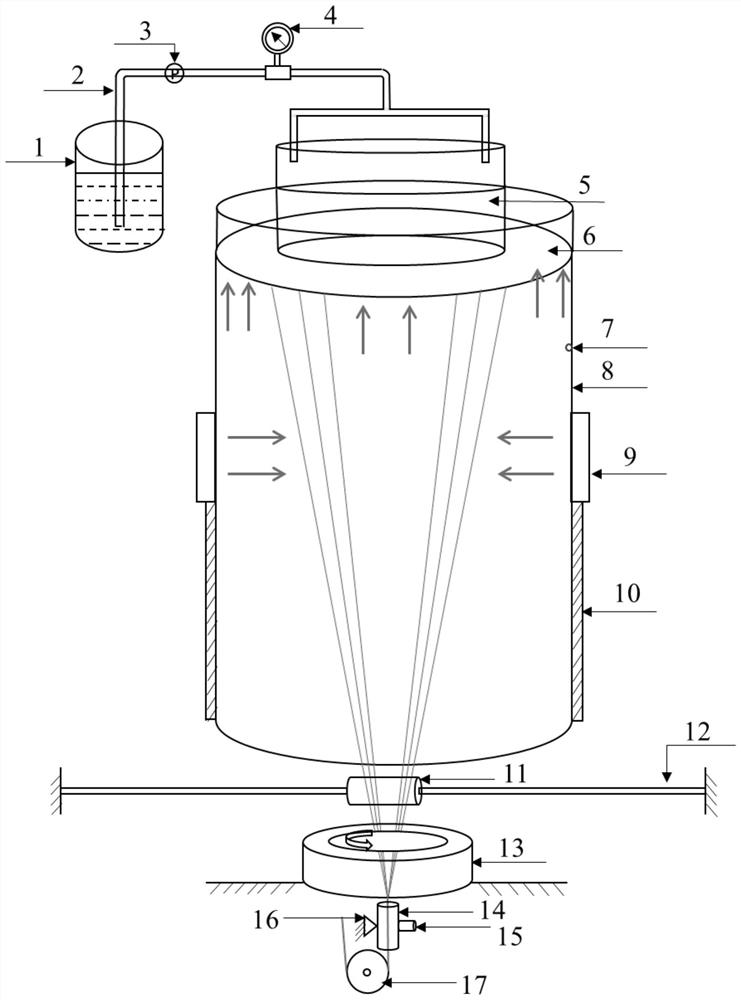

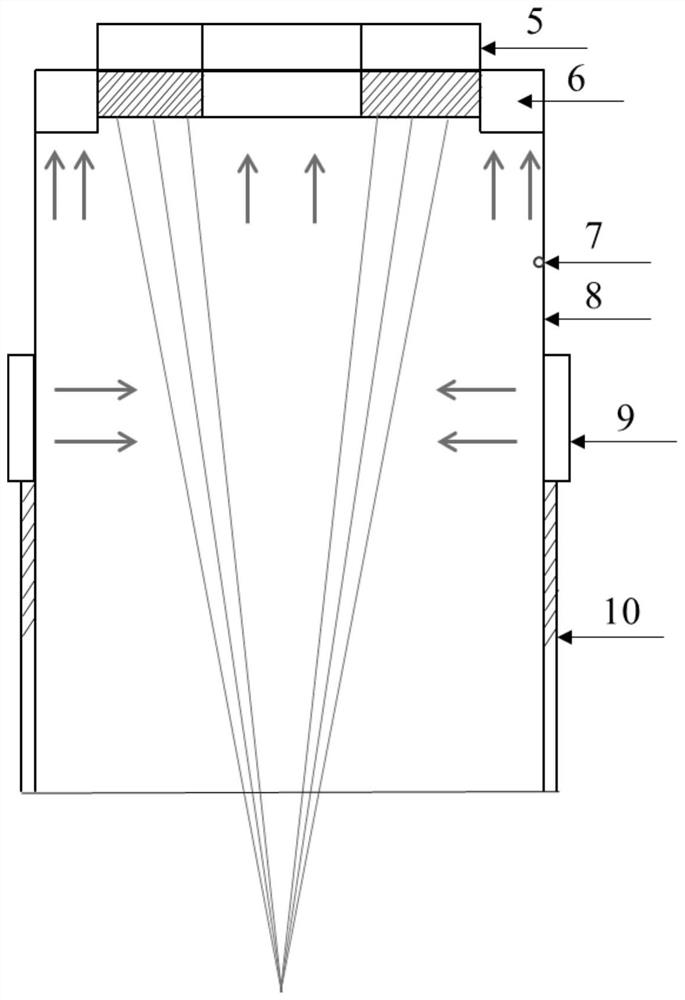

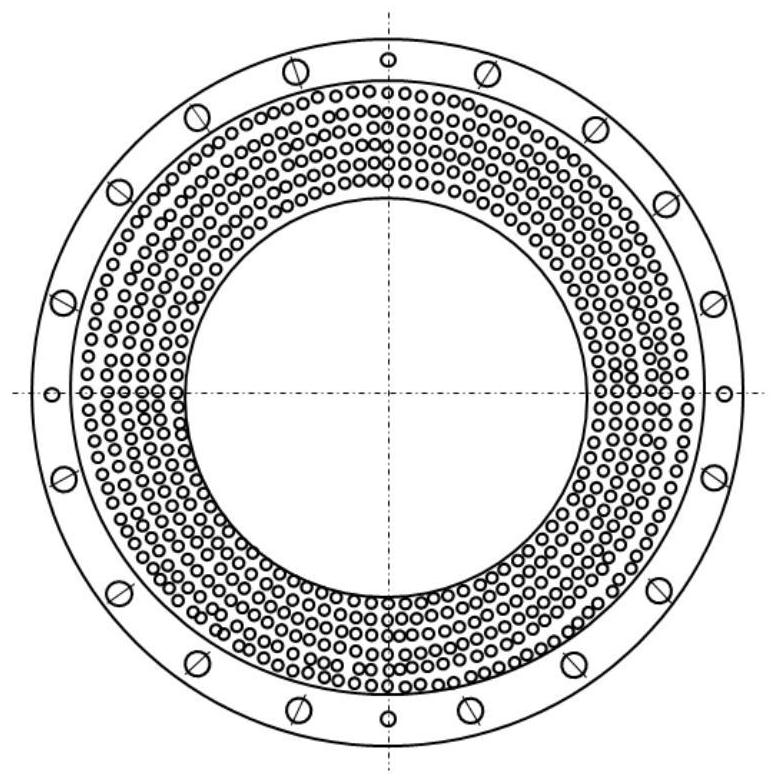

[0034] An industrial grade alumina continuous fiber thousand-hole spinning shaft and a bundling device, the device includes a liquid feeding device 1, a liquid suction device 2, a spinneret assembly 5, a shaft body 8, an upper annular blowing device 6, and a side annular blowing device. Air blowing device 9, annular heating device 10, oiling device 11, cross bar 12, twisting device 13, air supply device 14, drafting device 17; one end of the liquid suction device 2 is connected to the liquid feeding device 1, and the other end is connected to the liquid feeding device 1. The spinneret assembly 5 is connected; the spinneret assembly 5 and the upper annular blowing device 6 are located on the upper part of the shaft body 8, and the upper annular blowing device 6 is located outside the spinneret assembly 5; the side annular blowing device 9, the annular heating The device 10 is located on both sides of the shaft body 8, and the side annular blowing device 9 is located on the upper...

Embodiment 2

[0052] A spinning method of alumina fiber, the method adopts the thousand-hole spinning shaft and bundling device of industrial grade alumina continuous fiber described in Example 1.

[0053] Wherein, the length of the shaft body 8 is 8m; the humidity of the shaft body 8 is controlled at 75%, and the temperature is 25°C; min; the wind speed of the upper annular blowing device 6 is 0.4m / s, and the wind power is level 1; the height is 50mm; the wind speed of the side annular blowing device 9 is 0.4m / s, and the wind force is level 1; is 60mm; the flow velocity of the central hot air of the spinneret assembly 5 is 0.8m / s.

[0054] The obtained fibers are then sintered, and the sintering process is to sinter the fibers in stages under an air atmosphere. The first stage is low-speed and low-temperature sintering: the fibers are slowly heated to 700 °C at a lower heating rate (10 °C / min), and held for 30 minutes; ) The fibers are heated from 700°C to a specified temperature of 1100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com