Noble metal rhodium hydrogen evolution electrocatalyst and application

An electrocatalyst and noble metal technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problem of less research on Rh-based electrocatalytic catalysts, and achieve the effect of excellent electrochemical performance and low Rh content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

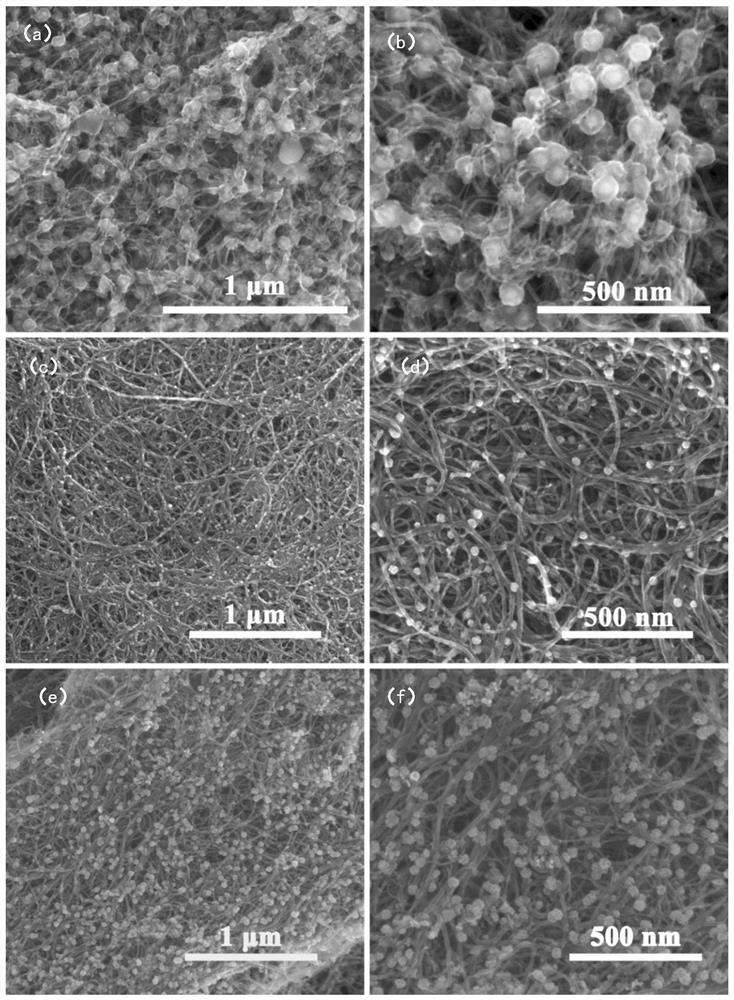

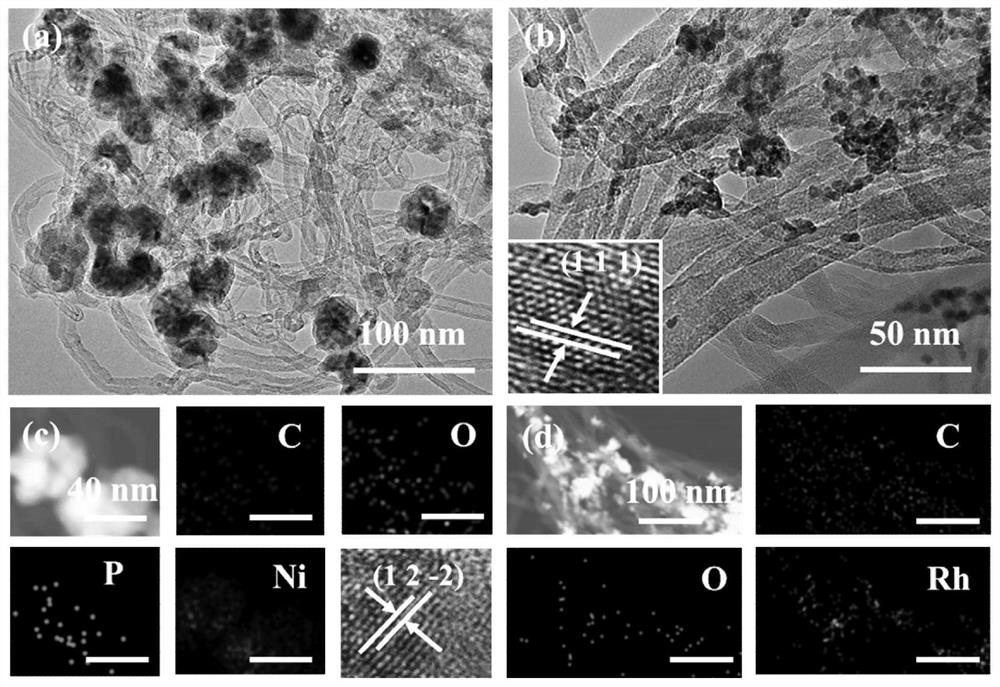

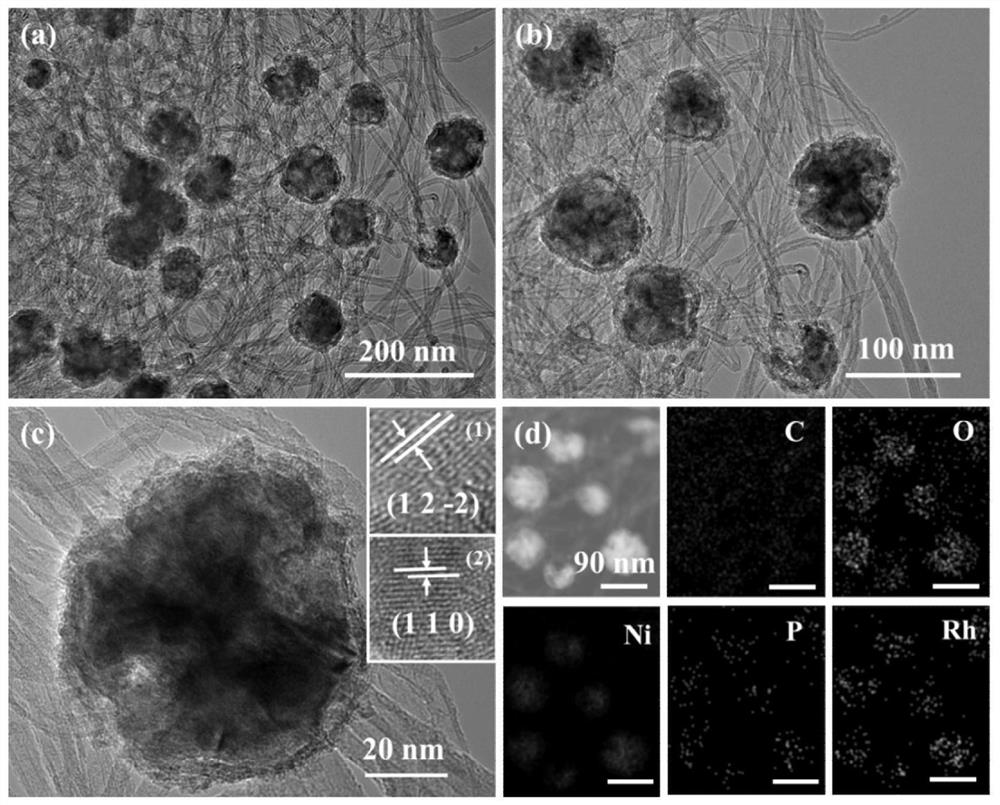

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] 1. Pretreatment of Glassy Carbon Electrodes

[0028] First, wipe the glassy carbon electrode with alcohol-moistened cotton, and then use polishing powders of different particle sizes (aluminum oxide, Al 2 o 3 ) (grain size: d = 0.3 μm, d = 0.05 μm) wetted on a polishing cloth for polishing. After each polishing session, the electrode is rinsed with ultrapure water before continuing with polishing. The final polishing step is performed on a polishing cloth with ultrapure water only. Polish for about 1.5 minutes each time, 3 times in total. After polishing, the glassy carbon electrode was placed in ultrapure water and ethanol solution for 30 s of ultrasonication. Finally, dry the surface of the glassy carbon electrode (using high-purity N 2 Airflow), le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com