Cathode arc head with double-layer shielding cover

A technology of shielding cover and cathode arc, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of long-term stable ablation of arc source, limited movement of arc spot, and cathode The target utilization rate is not high, so as to reduce the frequency of replacement, reduce the impact, and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

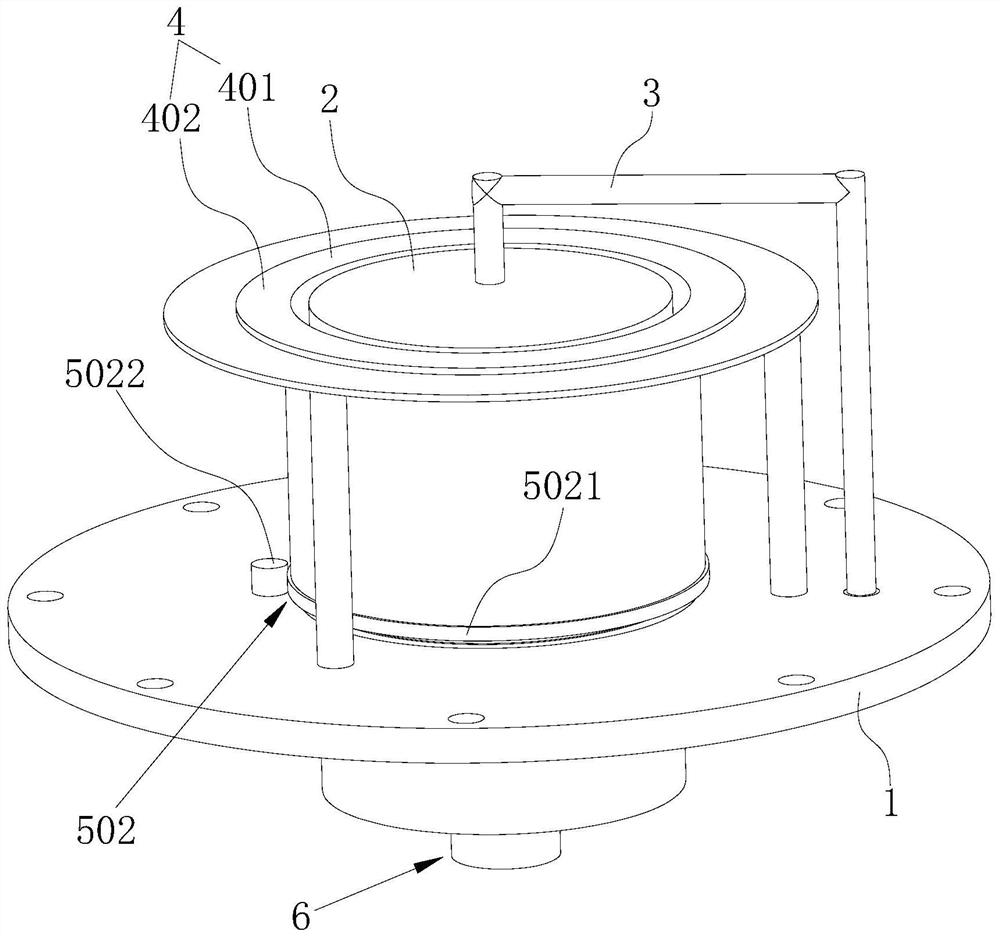

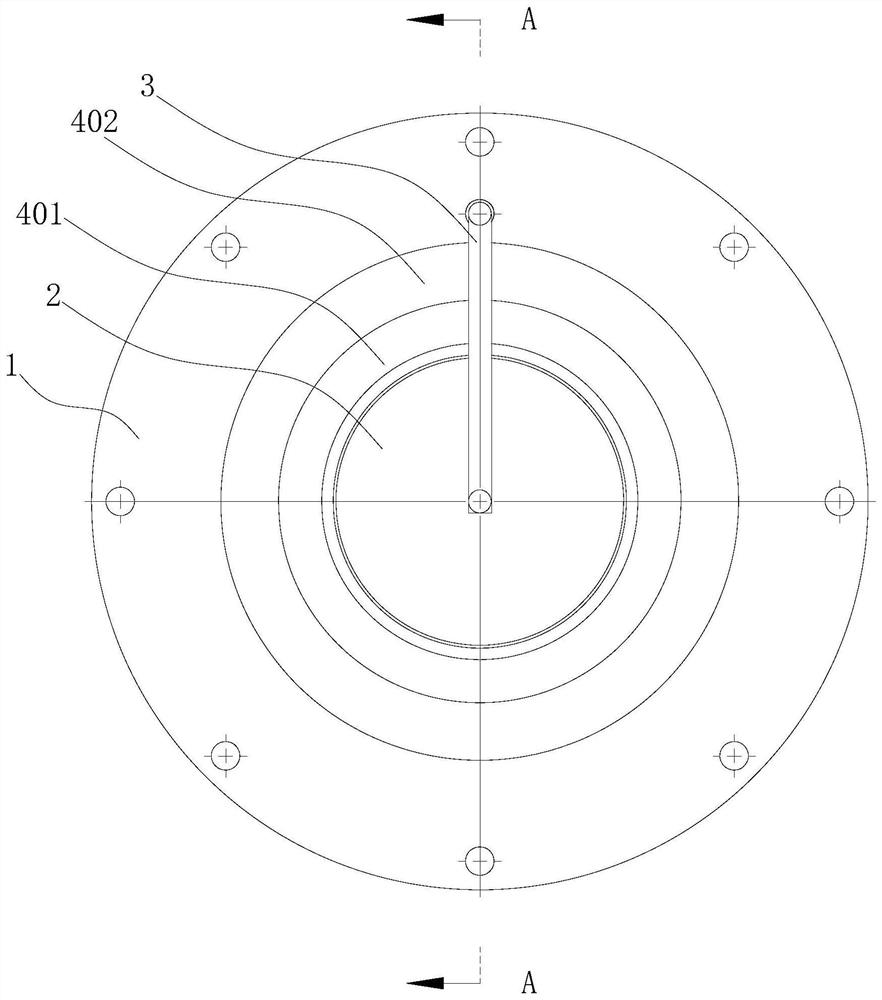

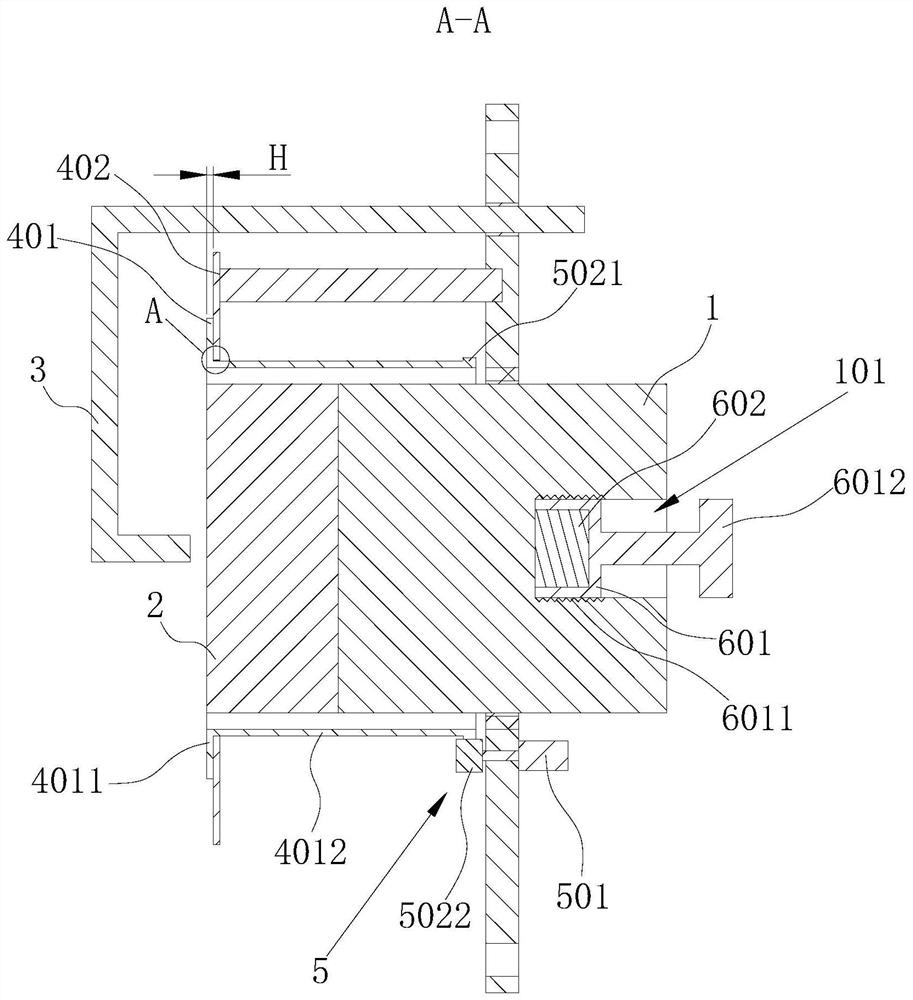

[0037] refer to figure 1 , figure 2 as well as image 3 , this embodiment discloses a cathode arc head with a double-layer shield, including a fixed flange 1, a cathode target 2, a trigger electrode 3, a shielding system 4, an auxiliary anode plate (not shown in the figure), and a cathode The target material 2 is fixed on the fixed flange 1, and the trigger electrode 3 is rotatably arranged on the fixed flange 1. This is an existing structure, and will not be repeated here.

[0038] refer to figure 1 , figure 2 , image 3 as well as Figure 4 , the shielding system 4 includes a first shielding case 401 and a second shielding case 402, the first shielding case 401 and the second shielding case 402 are coaxially arranged with the cathode target 2, and the first shielding case 401 and the second shielding case 402 Both are placed outside the cathode target 2 and keep a distance of 1 mm to 10 mm between the cathode target 2 in the radial direction. The first shield 401 and...

Embodiment 2

[0049] This embodiment discloses another cathode arc head with a double-layer shield. Based on Embodiment 1, the differences between this embodiment and Embodiment 1 are:

[0050] The rotating drive assembly includes a drive motor and a transmission assembly. The drive motor is fixed on the fixed flange. The transmission assembly includes a transmission chain ring, a transmission sprocket wheel, and a chain belt. The transmission chain ring is arranged on the outer wall of the first shielding case. The transmission chain ring includes Meshing teeth, the meshing teeth of the chain belt and the transmission chain ring and the transmission sprocket;

[0051] The transmission sprocket and the drive motor shaft are fixed, and the drive sprocket and drive motor shaft can pass through spline couplings, involute spline couplings, axially movable radial key rigid couplings, drum-shaped One of the methods of gear coupling or feather key connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com