Rapid dehydration method for dirty oil

A technology for rapid dehydration and slop oil, which is applied in the petroleum industry, processing hydrocarbon oil, and only multi-stage series refining process treatment, etc. The effect of shortening the settling distance, increasing the treatment capacity and enhancing the dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

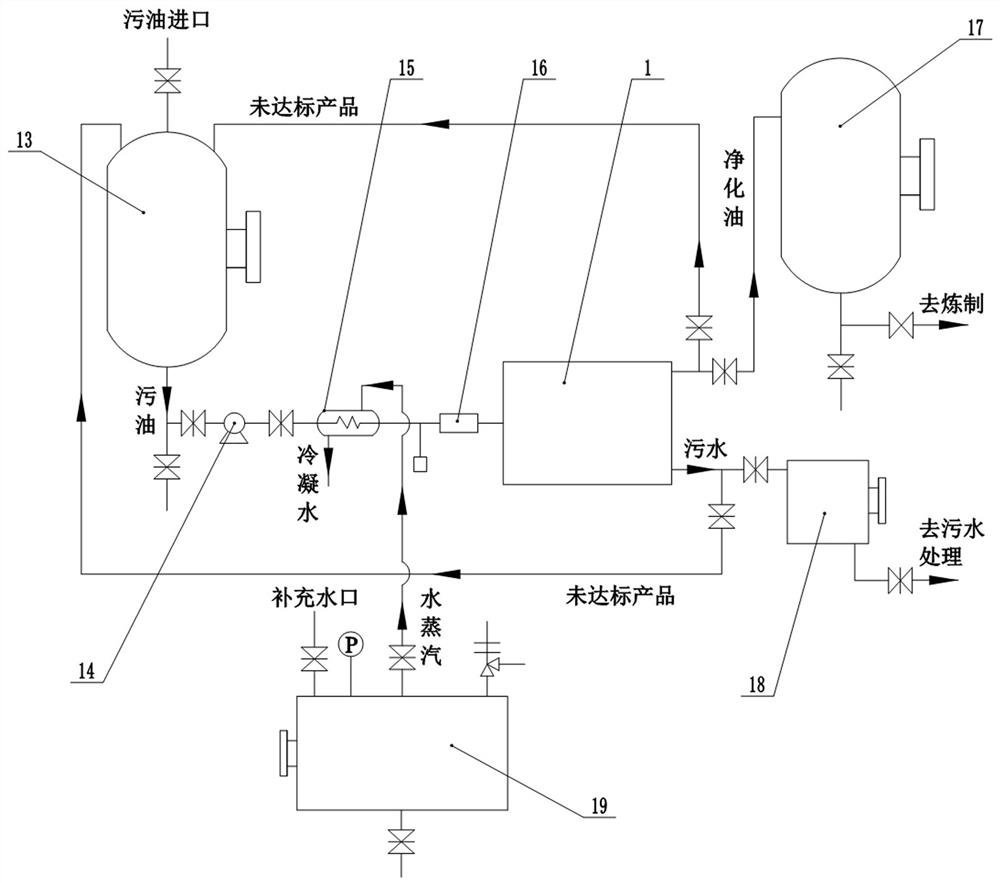

[0030] A method for quick dehydration of dirty oil. The dirty oil stored in the dirty oil storage tank 13 (the dirty oil is taken from a refinery, with a water content of 20%) is pumped into the heat exchanger 15 by the pump 14 for heating, and the dirty oil is After heating to 75 °C, the flow rate is adjusted to 0.3 m / h by the flow meter 16, and then enters the ultrasonic sedimentation integrated partition processor for processing. The heat exchanger is heated by a steam generator 19 . The overall flow chart of the treatment process is as follows figure 1 shown.

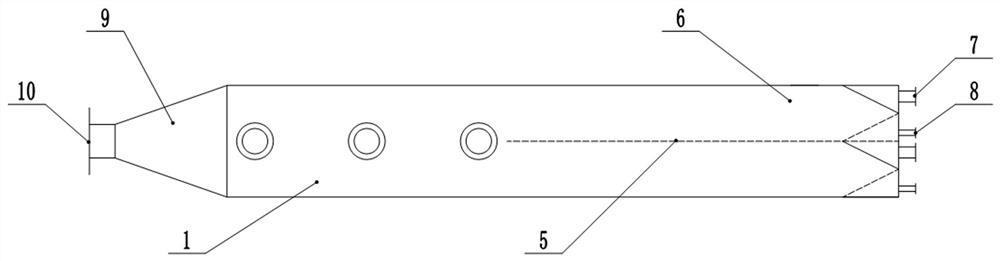

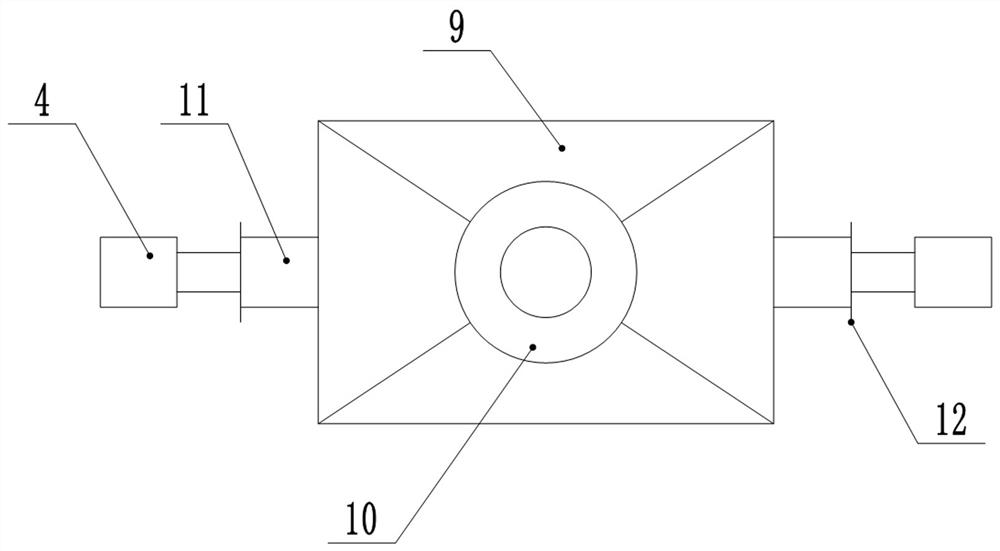

[0031] Such as Figure 2~Figure 4 As shown, the ultrasonic sedimentation integrated partition processor includes a housing 1 and an ultrasonic zone 2 and a sedimentation zone 3 sequentially arranged in the housing 1; the housing 1 is a cuboid, and the aspect ratio of the housing is 3:1. , height 200 mm. The ratio of the lengths of the ultrasonic zone 2 to the settling zone 3 is 1:30. An ultrasonic transducer 4 ...

Embodiment 2

[0039] Same as Example 1, the only difference is that the dirty oil is heated to 75 °C, the flow rate is adjusted by the flowmeter to 0.3 m / h, the aspect ratio of the shell is 3.5:1, and the ratio of the length of the ultrasonic zone to the settlement zone 1:35, the number of horizontal partitions is 2, and the ultrasonic sound intensity in the ultrasonic area is 0.65 W / cm 2 . The time for dirty oil to flow through the ultrasonic zone is 25 minutes, and the time for dirty oil to flow through the settling zone is 11 hours.

[0040] The dirty oil is the same as in Example 1, the initial water content of the dirty oil is 20%, and after treatment, the water content of the purified oil is 0.85%.

Embodiment 3

[0042] Same as Example 1, the only difference is that the dirty oil is heated to 80 °C, the flow rate is adjusted by the flowmeter to 0.3 m / h, the aspect ratio of the shell is 4:1, and the ratio of the length of the ultrasonic zone to the settlement zone 1:40, the number of horizontal partitions is 3, and the ultrasonic sound intensity in the ultrasonic area is 0.70 W / cm 2 . The time for dirty oil to flow through the ultrasonic zone is 30 minutes, and the time for dirty oil to flow through the settling zone is 10 hours.

[0043] The dirty oil is the same as in Example 1, the initial water content of the dirty oil is 20%, and after treatment, the water content of the purified oil is 0.71%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com