A kind of anti-collapse tundish dry vibrating material and preparation method thereof

A vibrating material and anti-slump technology, applied in the field of refractory materials, can solve the problems of non-adherent production, collapse, local peeling, etc., and achieve the effects of improving toughness and air permeability, relieving stress and reducing shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

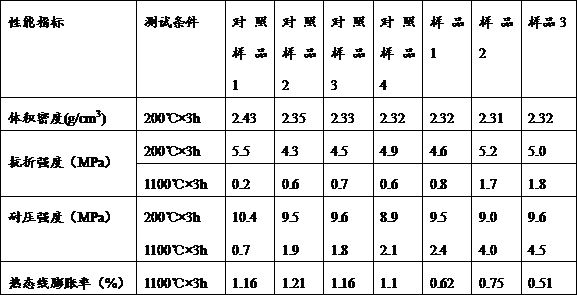

Examples

Embodiment 1

[0037] Preparation of control sample 1: Pour 93 parts of fused magnesia into the sand mixer and mix for 2 minutes, add 3 parts of additives, stir, and then pour 5 parts of phenolic resin binder (phenolic resin is the raw material produced by our factory, the other The market sales model is D012), after stirring evenly, obtain the control sample 1; wherein, the additives are soft clay, bentonite and boric acid; soft clay, bentonite and boric acid are mixed according to the weight ratio of 1:1:1; phenolic resin The market sales model for our self-produced raw materials is D012; fused magnesia MgO≥95%, SiO 2 3.2g / cm 3 ; Fused magnesia is 23 parts of fused magnesia with particle size ≤ 0.75; 20 parts of fused magnesia with particle size ≤ 1mm; 30 parts with 1< particle size ≤ 3mm; 20 parts of fused magnesia with a diameter ≤ 5mm. The fused magnesia in the following samples is the same as that of the control sample 1, and will not be repeated here.

[0038] Preparation of control...

Embodiment 2

[0050] Preparation of sample 2: Pour 93 parts of fused magnesia into the sand mixer and mix for 2 minutes, add 4 parts of additives, stir, then pour 6 parts of glucose, stir well, add 0.5 parts of organic fiber and 0.5 parts of glass Fiber, after stirring evenly, sample 2 is obtained; wherein, the additives are soft clay, bentonite, boric acid, metal silicon powder and silicon carbide micropowder, and the weight ratio of soft clay, bentonite, boric acid, metal silicon powder and silicon carbide micropowder is 1 :1:1:0.5:0.5 mixed; the organic fiber is polypropylene fiber, the length is 3mm, the diameter is 20-40μm, and the melting point is 160-170℃; the glass fiber is alkali-free borosilicate glass, the length is 3 -5mm, diameter 30-50μm, melting point 500-750℃.

[0051] Sample 2 was made into two cuboid samples of 40mm×40mm×160mm, which were demoulded after being kept at 200°C for 3 hours. After ×3h heat treatment, measure its flexural strength at room temperature, compressi...

Embodiment 3

[0054] Preparation of sample 3: Pour 93 parts of fused magnesia into the sand mixer and mix for 2 minutes, add 4 parts of additives, stir, then pour 6 parts of glucose, after stirring evenly, add 0.25 parts of organic fiber and 0.5 parts of plant Fiber and 0.25 parts of glass fiber, after stirring evenly, sample 3 is obtained; wherein, the additives are soft clay, bentonite, boric acid, metal silicon powder and silicon carbide micropowder, soft clay, bentonite, boric acid, metal silicon powder and silicon carbide The fine powder is mixed according to the weight ratio of 1:1:1:0.5:0.5; the organic fiber is polypropylene fiber, the length is 3mm, the diameter is 20-40μm, and the melting point is 160°C-170°C; the plant fiber is paper fiber, the length 2mm, diameter 10-20μm, melting point 300-500℃; glass fiber is alkali-free borosilicate glass, length 3-5mm, diameter 30-50μm, melting point 500-750℃.

[0055] Sample 3 was made into two cuboid samples of 40mm×40mm×160mm, which were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com