A kind of non-excavation spray plastic repair material and preparation method of in-service drainage pipeline

A technology for drainage pipes and repair materials, which is applied in sewer pipe systems, waterway systems, water supply devices, etc. It can solve the problems of unsatisfactory anti-seepage effect, long construction period, and prone to hollowing, etc., so as to reduce repair steps and cost, Low cost, effect of preventing hollowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

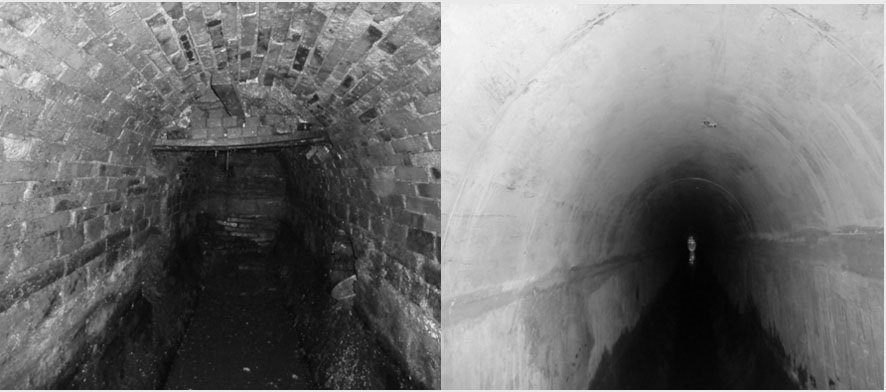

Image

Examples

Synthetic example

[0025] The water purification sludge of Suzhou High-tech Zone Waterworks was dried at 100°C for 24 hours and then pulverized, and 800 mesh to 1000 mesh was taken as the water purification sludge of the following examples and comparative examples.

[0026] The commercially available zeolite powder (Huaqing zeolite) was soaked in a mixed aqueous solution of 0.1 mol / L hydrochloric acid and 0.2 mol / L sodium sulfate at room temperature for 24 hours, then rinsed with water, calcined in air at 350 °C for 2 hours, and ground with The machine is ground to 200 mesh to obtain the modified zeolite powder; soaking is a conventional method, and the liquid can pass the solid.

Embodiment

[0028] The fly ash, water purification sludge, and metakaolin are conventionally mixed and ball-milled for 30 minutes, and then conventionally mixed with cement to obtain a cementitious material.

[0029] Mix the cementitious material, quartz sand, modified zeolite powder, latex powder, polyvinyl alcohol, fiber material, water-retaining agent, retarder, epoxy resin, and water (half of the total) to obtain component A, and wet the Mixing agent, curing agent, and water (the remaining amount) to obtain component B; mixing component A and component B to obtain a non-excavation spray-plastic repair material for in-service drainage pipes; mixing is a conventional method.

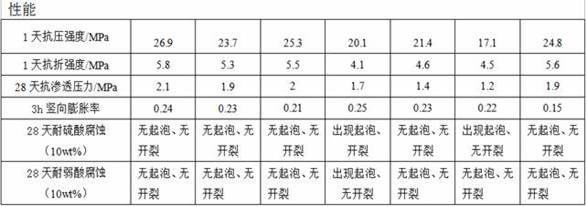

[0030] The present invention provides the following Examples 1-6 to specifically illustrate the components of the trenchless spray plastic repair material for in-service drainage pipes, as shown in Table 1 below.

[0031]

[0032]

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com