Preparation method of hexavalent chromium reducing agent for nano-loaded cement

A loaded, hexavalent chromium technology, which is applied in the field of building materials, can solve problems such as water solubility, and achieve the effects of increased reduction efficiency, low dosage, and high reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

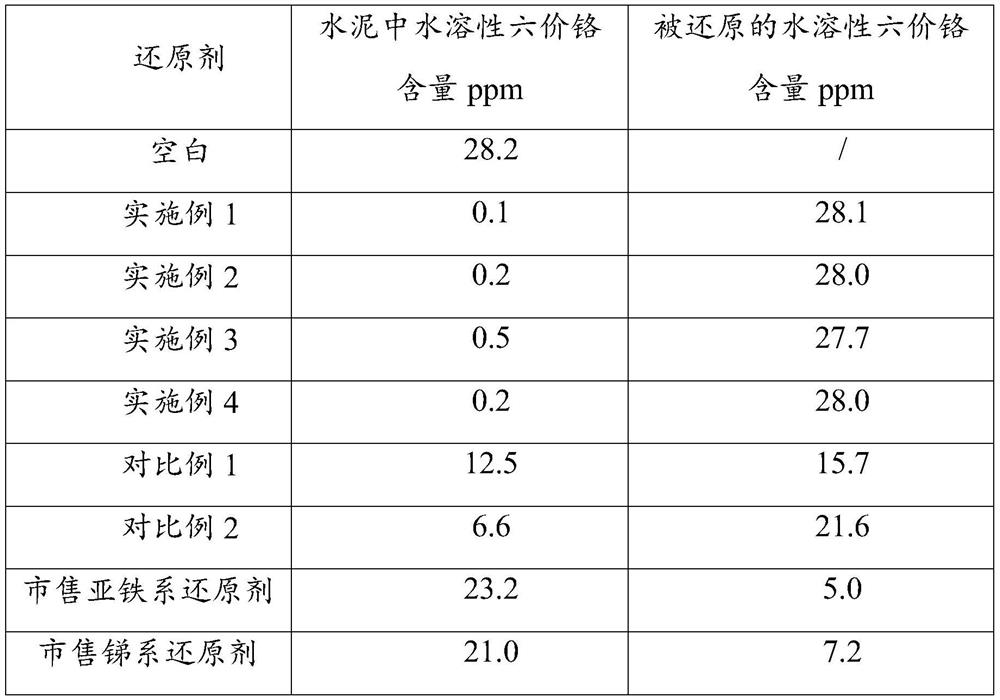

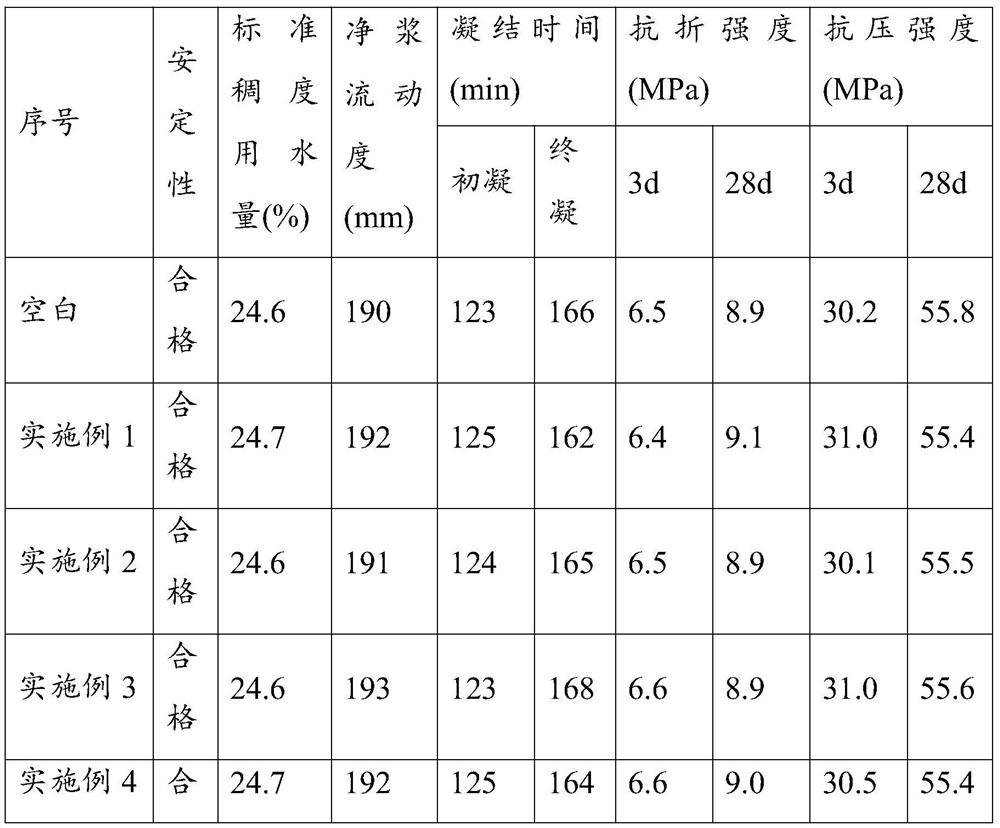

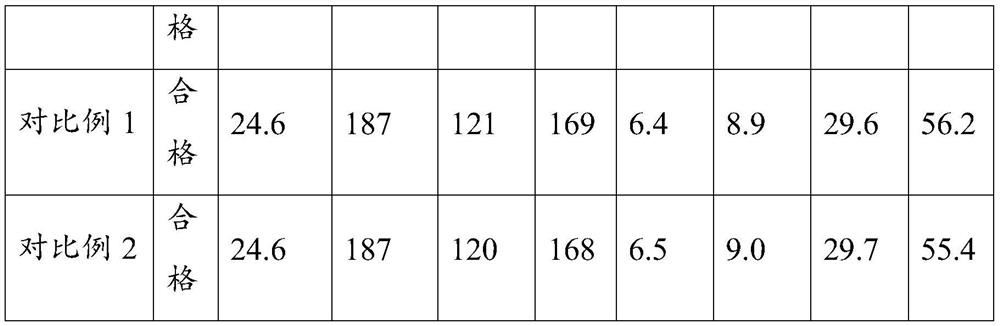

Examples

Embodiment 1

[0022] A method for preparing a hexavalent chromium reducing agent for nano-loaded cement, comprising the following steps:

[0023] (1) Weigh 2 g of antimony trichloride, place it in a three-neck glass flask, and place the glass flask in a constant temperature water bath at 30°C.

[0024] (2) Use a constant pressure funnel to add the ethylenediamine solution dropwise to the glass flask, the ratio of the ethylenediamine solution to antimony trichloride is 100:1, and use a constant speed electric stirrer to stir the solution. 500r / min.

[0025] (3) Add wollastonite into the flask, the mass ratio of wollastonite to antimony trichloride is 0.2:1, and continue to stir for 30 minutes.

[0026] (4) After the suspension was allowed to stand for 30 minutes, it was suction-filtered, washed twice with deionized water and alcohol, and the obtained solid was dried in an oven at 80° C. for 4 hours.

Embodiment 2

[0028] A method for preparing a hexavalent chromium reducing agent for nano-loaded cement, comprising the following steps:

[0029] (1) Weigh 2 g of antimony trichloride, place it in a three-neck glass flask, and place the glass flask in a constant temperature water bath at 60°C.

[0030] (2) Use a constant pressure funnel to add ethylenediamine solution dropwise to the glass flask, the ratio of ethylenediamine solution to antimony trichloride is 60:1, and use a constant speed electric stirrer to stir the solution. 1000r / min.

[0031] (3) Add wollastonite into the flask, the mass ratio of wollastonite to antimony trichloride is 1:1, and continue to stir for 120 minutes.

[0032] (4) After the suspension was allowed to stand for 60 minutes, it was suction-filtered, washed five times with deionized water and alcohol respectively, and the obtained solid was dried in an oven at 80° C. for 4 hours.

Embodiment 3

[0034] A method for preparing a hexavalent chromium reducing agent for nano-loaded cement, comprising the following steps:

[0035] (1) Weigh 2 g of antimony trichloride, place it in a three-necked glass flask, and place the glass flask in a constant temperature water bath at 45°C.

[0036] (2) Use a constant pressure funnel to add ethylenediamine solution dropwise to the glass flask, the ratio of ethylenediamine solution to antimony trichloride is 50:1, and use a constant speed electric stirrer to stir the solution. 800r / min.

[0037] (3) Add wollastonite into the flask, the mass ratio of wollastonite to antimony trichloride is 2:1, and continue to stir for 80 minutes.

[0038] (4) After the suspension was allowed to stand for 45 minutes, it was suction-filtered, washed three times with deionized water and alcohol respectively, and the obtained solid was dried in an oven at 80° C. for 4 hours.

[0039] In the above embodiment 1-embodiment 3, the ethylenediamine solution can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com