Intelligent monitoring high-precision positioning drum hoisting device and hoisting method applied by same

A hoisting device and intelligent monitoring technology, applied in safety devices, hoisting devices, transportation and packaging, etc., can solve the difficulty of adjusting the real-time position of the boiler steam drum, it is difficult to ensure a relatively vertical state, and the position adjustment of the steam drum is prone to deviation and other issues, to achieve considerable economic benefits, light weight, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

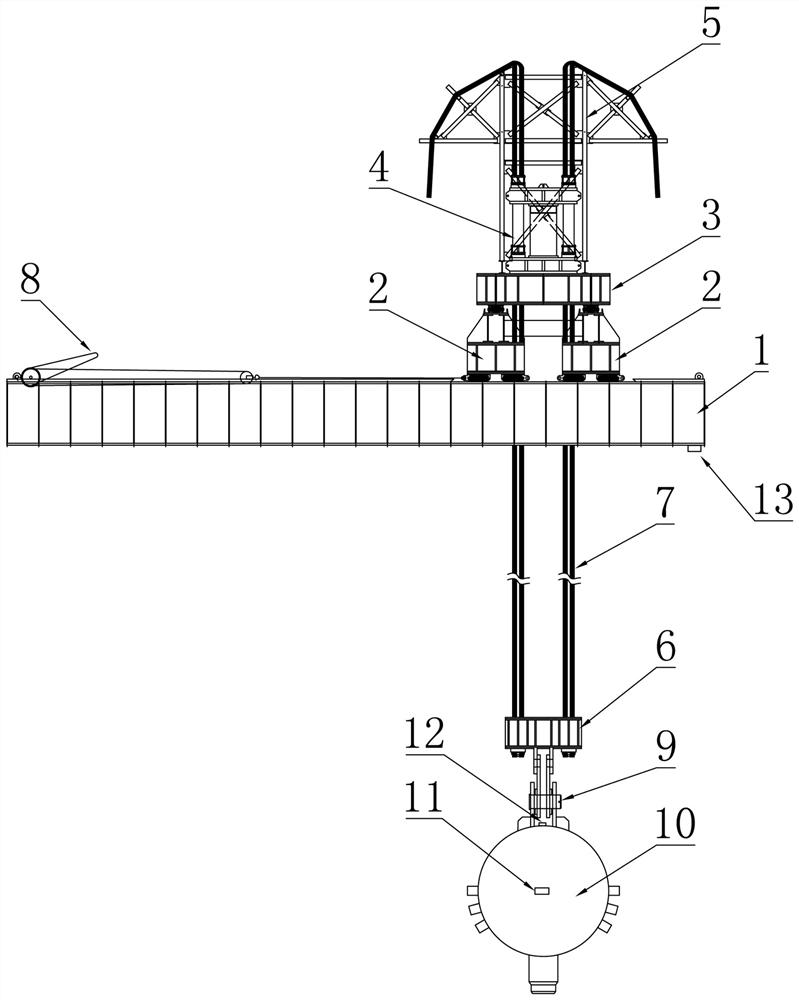

[0051] Embodiment 1 An intelligent monitoring and high-precision positioning steam drum hoisting device

[0052] Such as figure 1 As shown, this embodiment includes a steel strand 7, a support beam assembly, a hydraulic lifting assembly 4, and a monitoring and alarm assembly. In this embodiment, the spatial verticality of the boiler drum 10 is measured in real time through the monitoring and alarm component, and is not affected by the weather or other human factors on site. During the hoisting process, it can provide a basis for the staff to adjust the position of the boiler drum 10 , thereby ensuring the safety and stability of the hoisting process of the boiler steam drum 10 .

[0053] 1. Support beam components

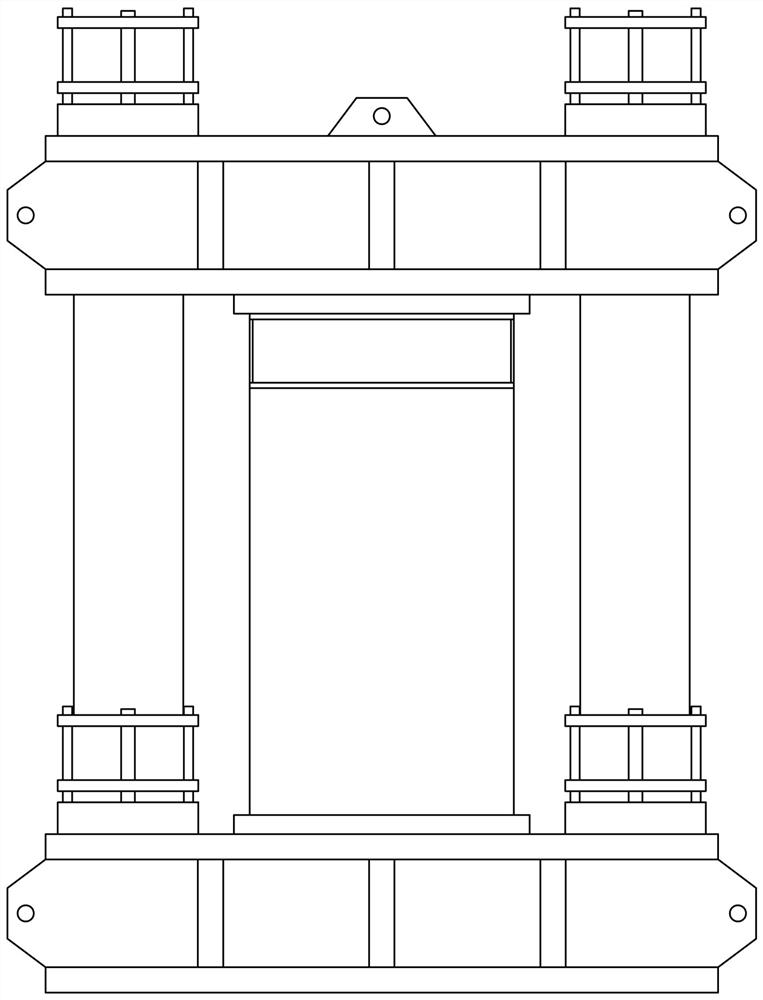

[0054] The support beam assembly is the core support structure of the steam drum hoisting device, which is used to fix the hydraulic lifting assembly 4 and bear the full weight of the boiler steam drum 10 during the hoisting process. In order to ensure that the ...

Embodiment 2

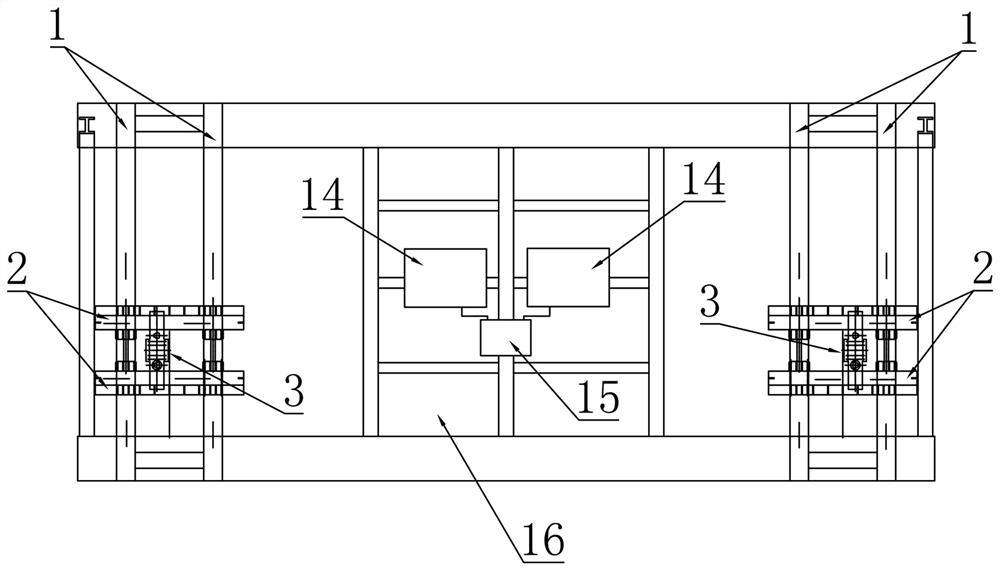

[0065] Example 2 A tilting hoisting method for a boiler drum with double hoisting points

[0066] This embodiment utilizes two groups of steam drum hoisting devices described in Embodiment 1 to hoist the boiler steam drum 10 in a manner of double hoisting point tilted hoisting, and during the hoisting process, the position of the boiler steam drum 10 can be checked in real time by monitoring and alarming. Monitoring can effectively prevent accidents from happening. The specific hoisting method is as follows:

[0067] Step S1, combined installation of steam drum hoisting device

[0068] a1. Use hoisting machinery to install two groups of steam drum hoisting devices on both sides of the top of the boiler respectively, and build a temporary operation platform 16 for the working surface, specifically as follows image 3 As shown, the operation platform 16 of the working face is provided with a hydraulic pump station 14 communicated with the hydraulic lifting assembly 4, and an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com