Super tonnage split lifting hook

A super-large-tonnage, split-type technology, applied in the direction of load-hanging components, portable lifting devices, hoisting devices, etc., can solve problems such as short service life, inability to withstand high-intensity and high-frequency operations, and insufficient lifting capacity. Long service life, improved operating efficiency, and large lifting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

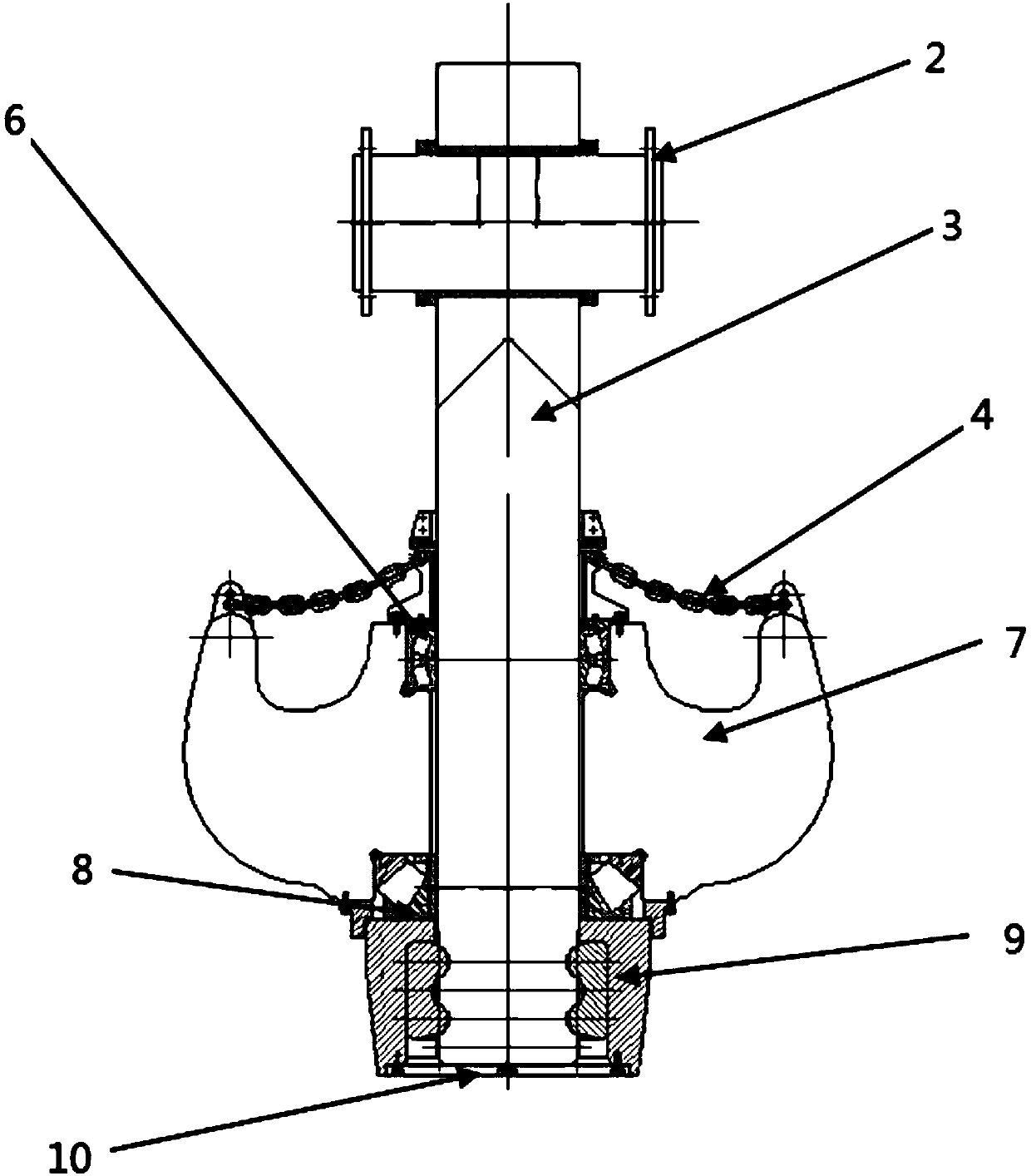

[0032] The following is attached Figure 1-8 , the present invention will be further elaborated by specifying a preferred specific embodiment.

[0033] Such as Figure 1-3 As shown, a super-large tonnage split hook of the present invention includes: moving pulley block, connecting beam 1, hook shaft 2, hook rod 3, anti-decoupling device 4, bearing cover 5, hook body 7, arranged on The self-aligning roller bearing 6 above the hook body 7, the thrust self-aligning roller bearing 8 arranged below the hook body 7, the connecting assembly 9 arranged below the thrust self-aligning roller bearing 8, the bottom cover 10, Screw plug 11 and dust cover 12. The self-aligning roller bearing 6 is also provided with a bearing cover and an anti-jumping device that can rotate with the hook body, and the top is a dust cover 12 fixed on the hook rod.

[0034] Described connecting beam 1 is connected with movable pulley block, and described movable pulley block is preferably two groups, and ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com