Automatic label removing assembly line based on spools

An assembly line and spool technology, which is applied in the direction of grinding feed motion, grinding drive device, grinding machine parts, etc. Spool quality assurance, easy transport process and reliable and stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

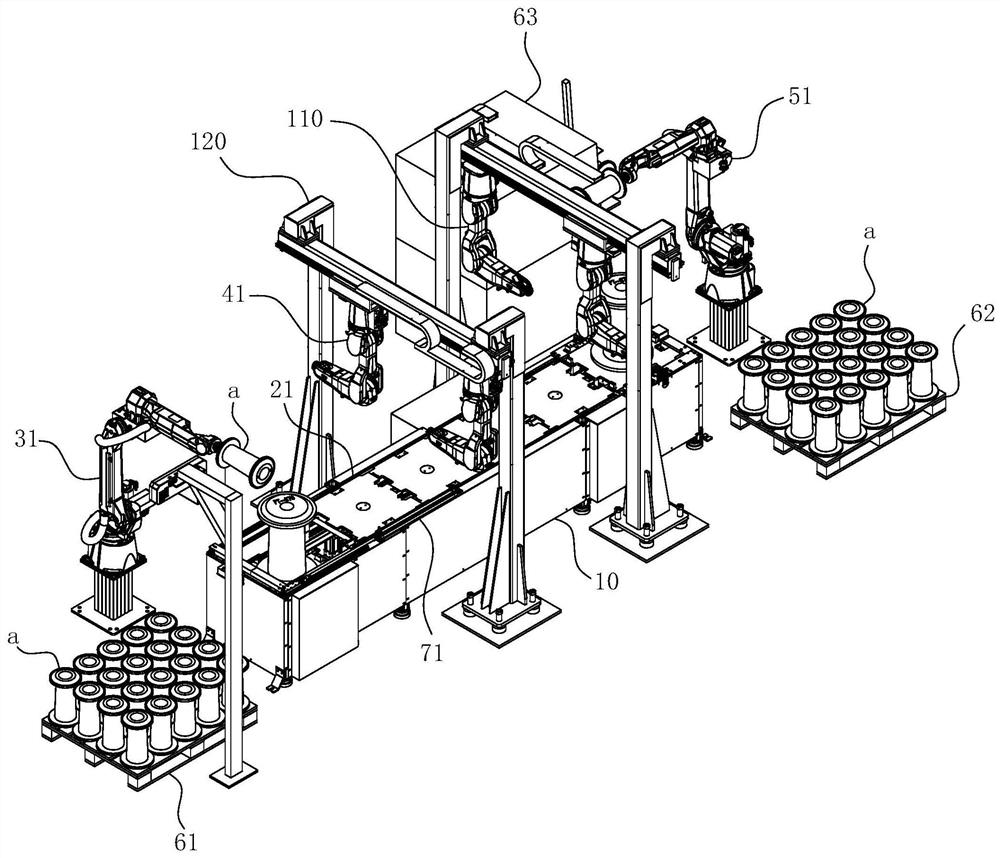

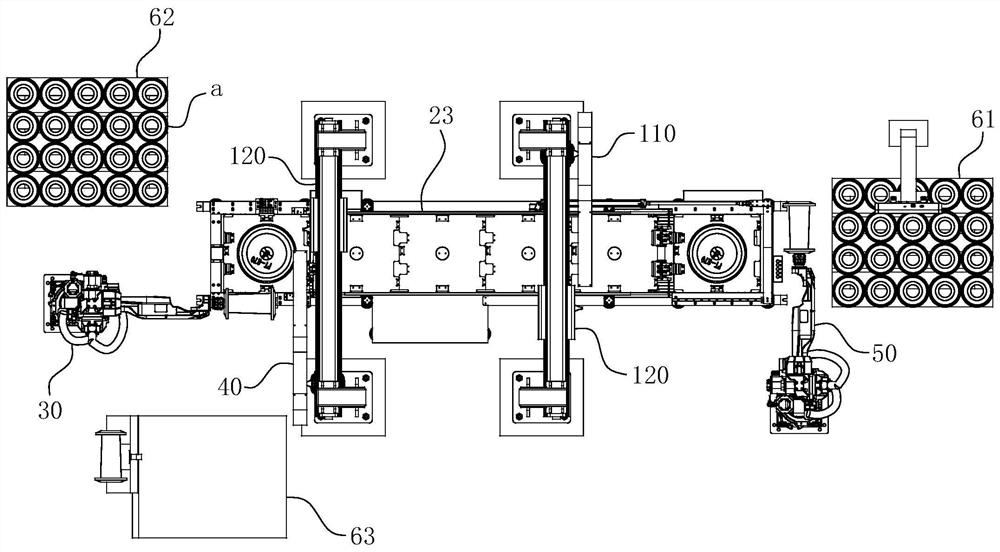

[0050] For ease of understanding, combined here Figure 1-12 , the concrete structure and working mode of the present invention are further described as follows:

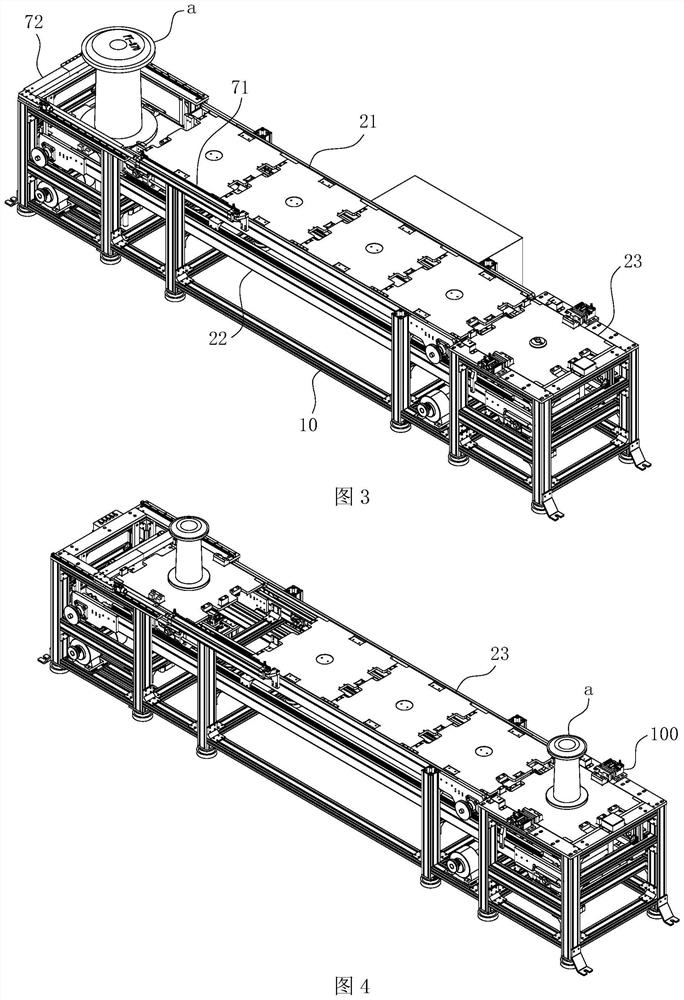

[0051] The specific structure of the present invention is as Figure 1-12 As shown, its main structure includes a feed conveyor belt 21 and a return conveyor belt 22 arranged in order from top to bottom on the frame 10 with a height difference. Along the conveying direction of the feeding conveyor belt 21 , the feeding assembly 30 , the demarking assembly 40 , the grinding assembly and the unloading assembly 50 are arranged in sequence. A loading tray 61 is arranged on one side of the feeding assembly 30 , and a cleaning table 63 and a reclaiming table 62 are arranged beside the feeding assembly 50 . in:

[0052] Both the feed conveyor belt 21 and the return conveyor belt 22 are preferably double-speed chains, that is, relying on two or more rows of conveyor rollers to support the conveyor plate 23 and transport ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com