Flat polishing machine for wafer processing

A polishing machine and surface cutting technology, which is applied in the direction of surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as burr splashing, polishing machine environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

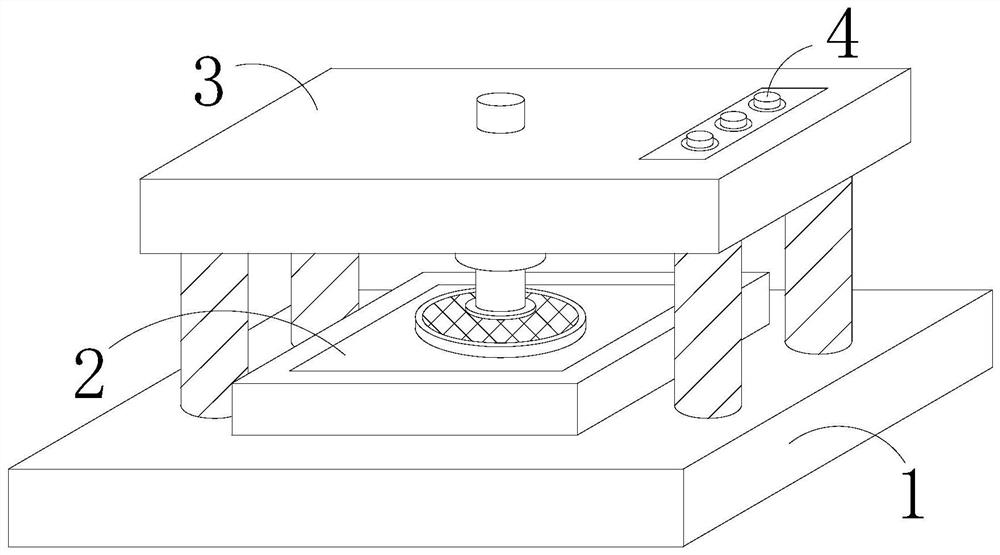

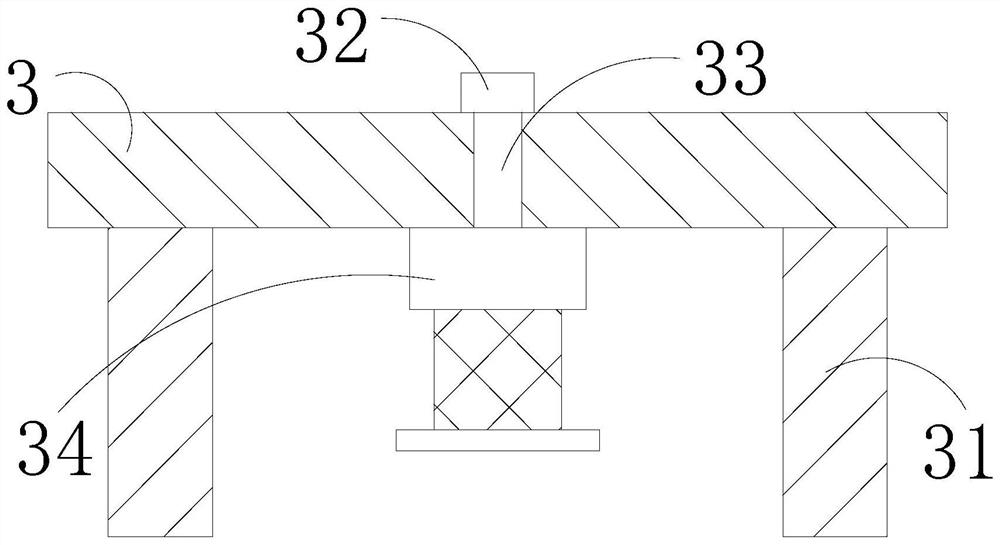

[0029] The present invention provides a surface polishing machine for wafer processing. Right above the workbench 1, the button 4 is embedded on the upper surface of the top plate 3. The top plate 3 includes a support rod 31, a turning block 32, a screw 33, and a polisher 34. The top of the support rod 31 is connected to the top plate by welding. 3 lower surface, and the bottom of the support rod 31 is embedded on the upper surface of the worktable 1, the rotating block 32 is installed just above the center of the top plate 3, the screw 33 is perpendicular to the center of the top plate 3 through bolts, and the top of the screw 33 is connected to the rotating The blocks 32 are welded together, the top of the polisher 34 is embedded in the lower surface of the top plate 3, there are four support rods 31, and the length of the polisher 34 after being extended is the shortest between the bottom of the top plate 3 and the upper surface of the polishing seat 2 The distance is conve...

Embodiment 2

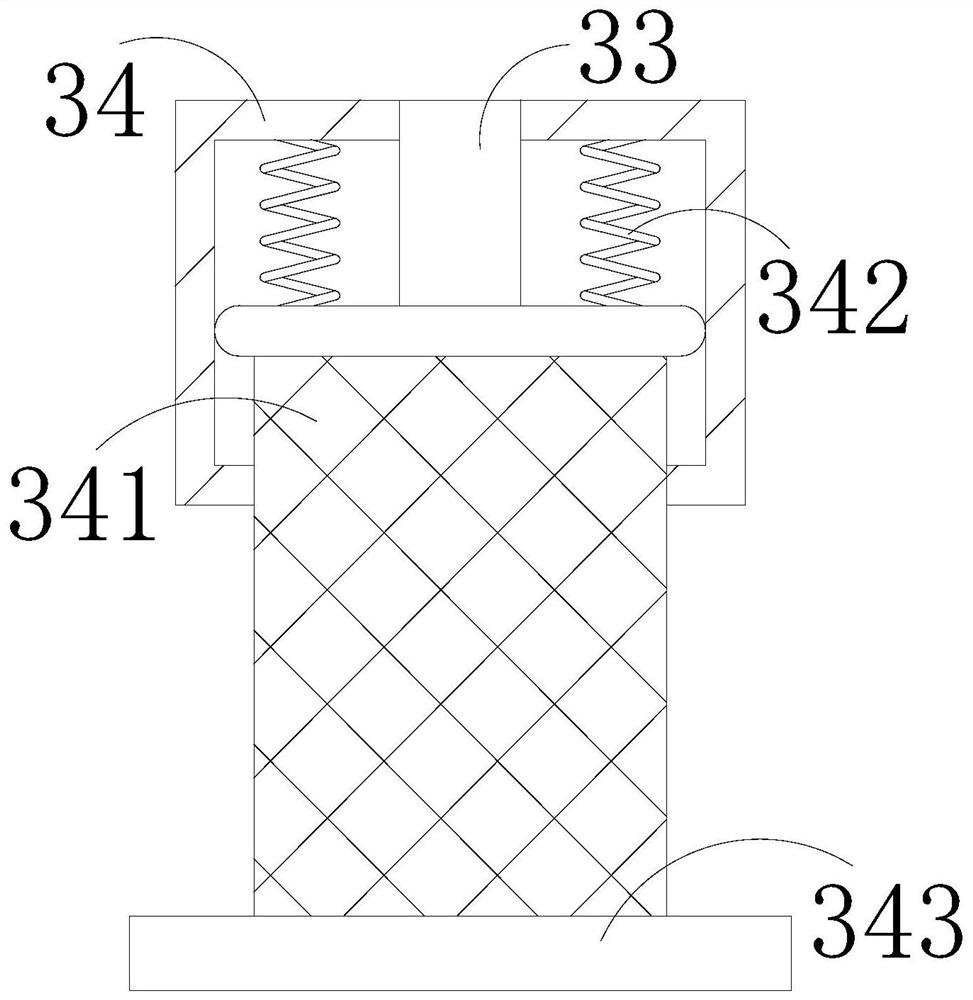

[0035]In the figure, the polisher 34 includes a telescopic rod 341, a tension spring 342, and a polishing knife 343. The telescopic rod 341 is connected to the inner bottom of the polisher 34 by a movable snap, and the tension spring 342 is connected to the telescopic rod 341 by welding. Between the top and the upper inner wall of the polisher 34, the upper surface of the polishing blade 343 is embedded in the bottom end of the telescopic rod 341, the interior of the polisher 34 is hollowed out, and the pulling force of the tension spring 342 is greater than the gravity of the telescopic rod 341, which is convenient for polishing After the knife 343 polishes the wafer, the telescopic rod 341 and the polishing knife 343 are pulled up by the pulling force of the tension spring 342 .

[0036] In the figure, the telescopic rod 341 includes a partition a1, an air extractor a2, a filter screen a3, a storage cylinder a4, and a through hole a5. The partition a1 is connected to the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com