Machining method for bending large plate into multi-edge-angle workpiece in one step

A processing method and multi-angular technology, which is applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problem of not being able to process multi-angular workpieces, and achieve the effect of reducing the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

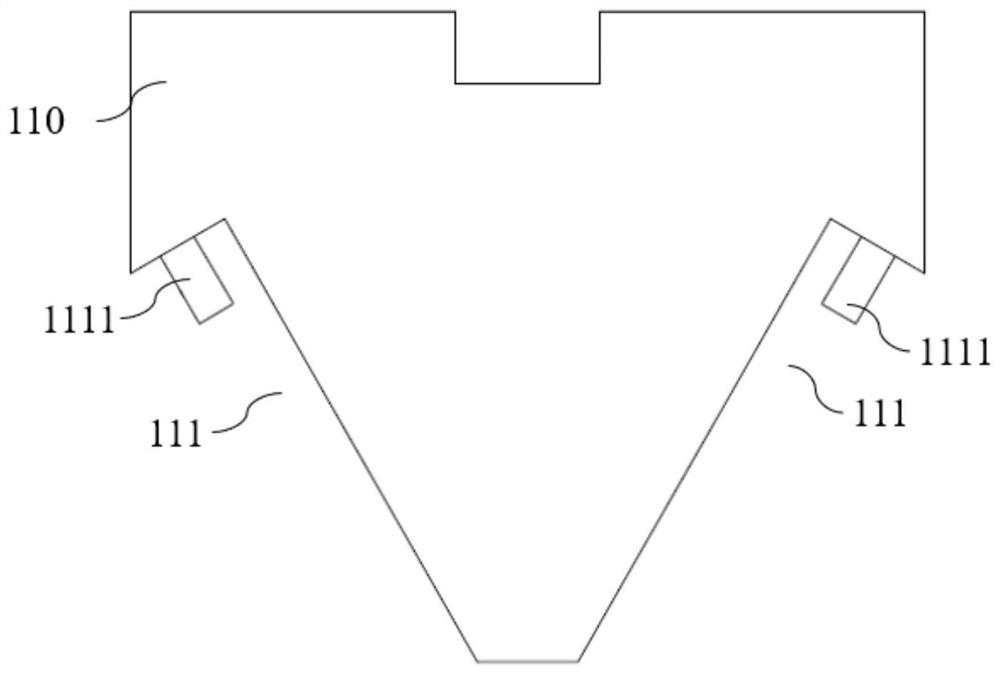

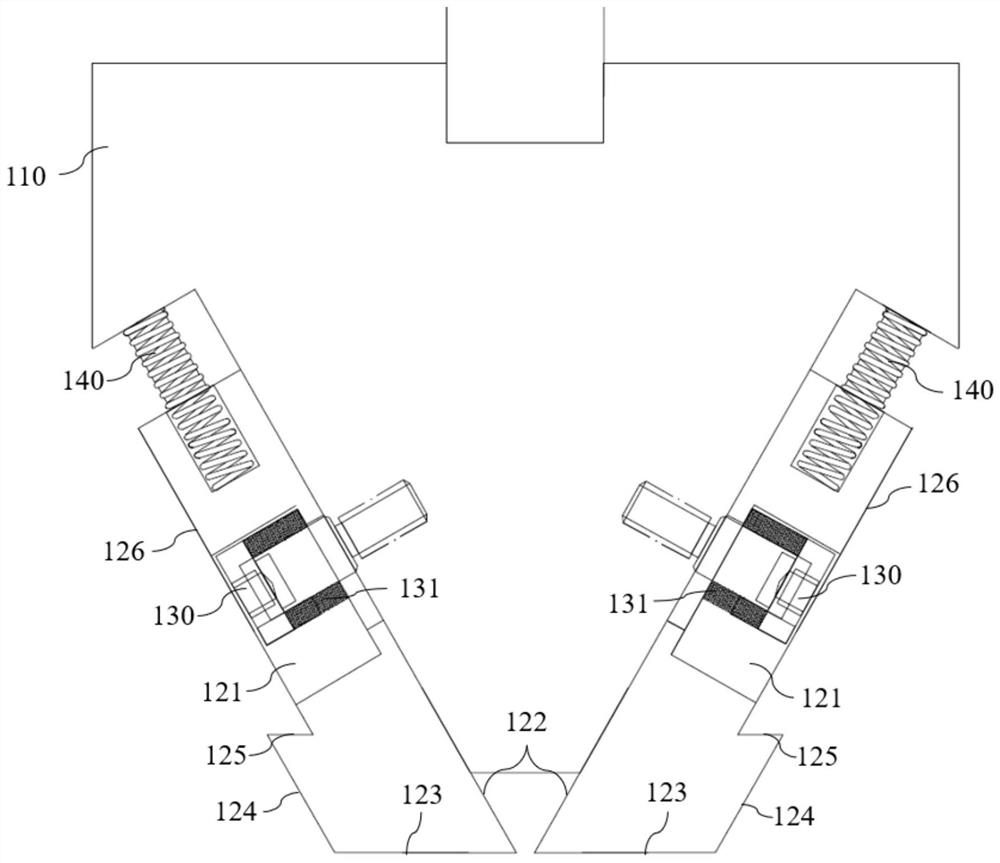

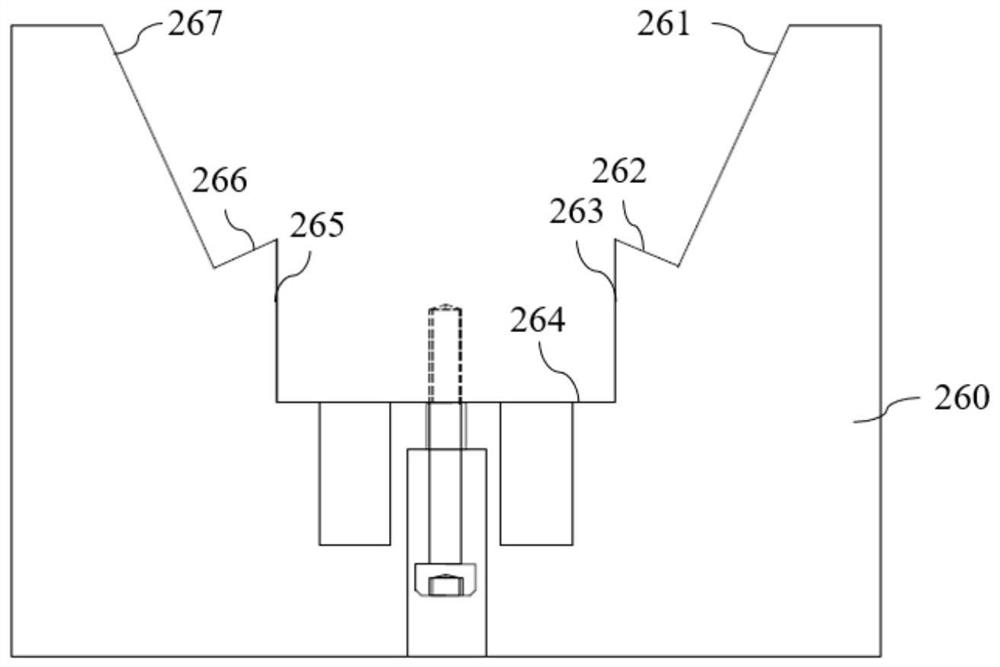

[0046] An automatic forming mold for one-time bending of large sheet metal with multiple corners in this embodiment includes an upper mold part 100 and a lower mold part 200, wherein the upper mold part 100 includes an upper mold pressing plate 110 and two left and right punches 120 And upper die holder 150;

[0047] Specifically, as figure 1 As shown, two square grooves—installation grooves 111 are respectively provided on the left and right sides of the upper mold pressing plate 110, and a punch 120 is respectively installed in the installation grooves 111, as figure 2 As shown, a chute 121 is provided in the middle of the punch 120, and a bolt 130 is installed in the chute 121 to fix the punch 120 on the mounting groove 111. It should be noted that the width of the chute 121 is greater than the width of the nut of the bolt 130, and The nut of the bolt 130 can slide in the chute 121. In another embodiment of this embodiment, in order to prevent the bolt 130 from loosening,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com