Solid-liquid separation device for kitchen garbage

A technology for solid-liquid separation and kitchen waste, applied in centrifuges, transportation and packaging, solid waste removal, etc., can solve problems such as inability to separate kitchen waste from solid-liquid and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

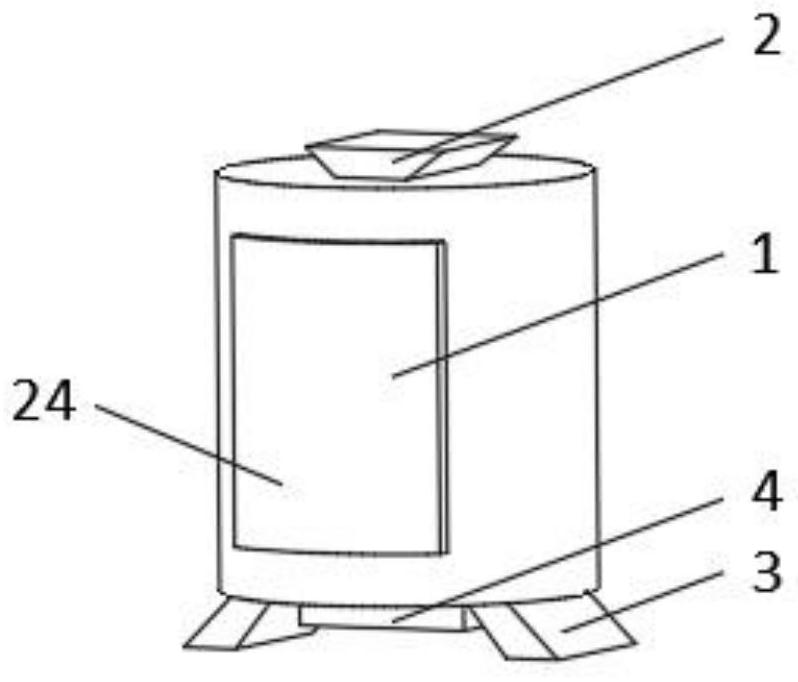

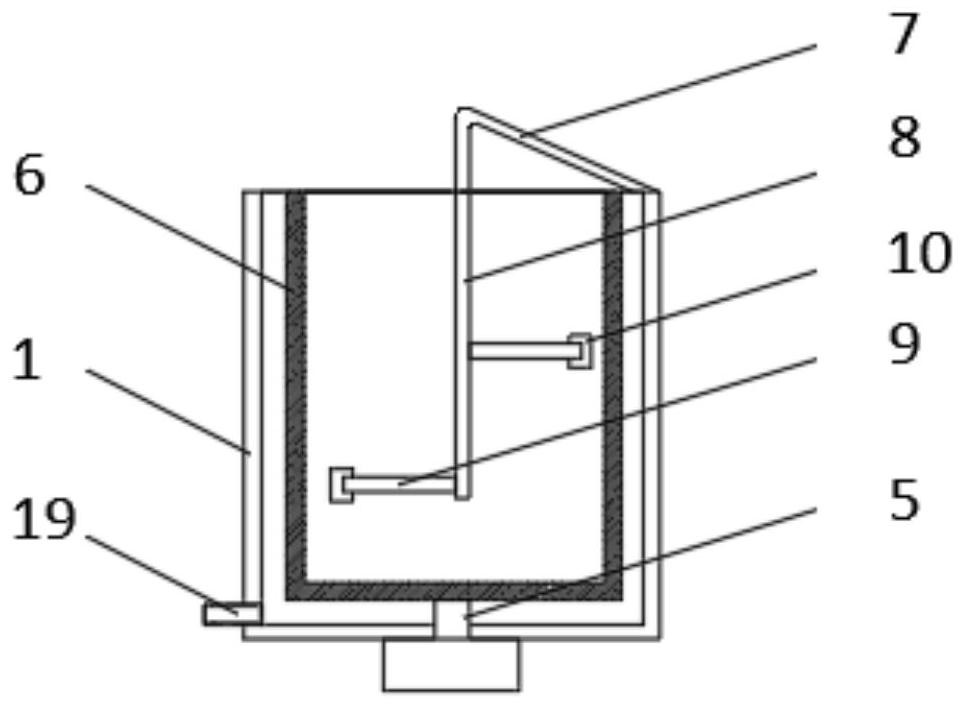

[0036] see Figure 1-3 , the present invention provides a technical solution: one comprising an outer frame 1, the top of the outer frame 1 is connected with a feed port 2, the bottom of the outer frame 1 is symmetrically installed with an underframe 3, and the side of the outer frame 1 close to the underframe 3 A motor 4 is installed, and the output end of the motor 4 is rotatably connected with a rotating rod 5, one end of the rotating rod 5 runs through the bottom of the outer frame 1, and the end of the rotating rod 5 away from the motor 4 is fixedly connected with an inner frame 6, which is an elastic mesh , an extension rod 7 is installed on the inner wall of the outer frame 1 close to the discharge port 2, and the end of the extension rod 7 away from the outer frame 1 is fixedly connected with a support column 8, and a bracket 9 is installed on the outside of the support column 8, and the bracket 9 is far away from the support column One end of 8 is connected with fixed...

Embodiment 2

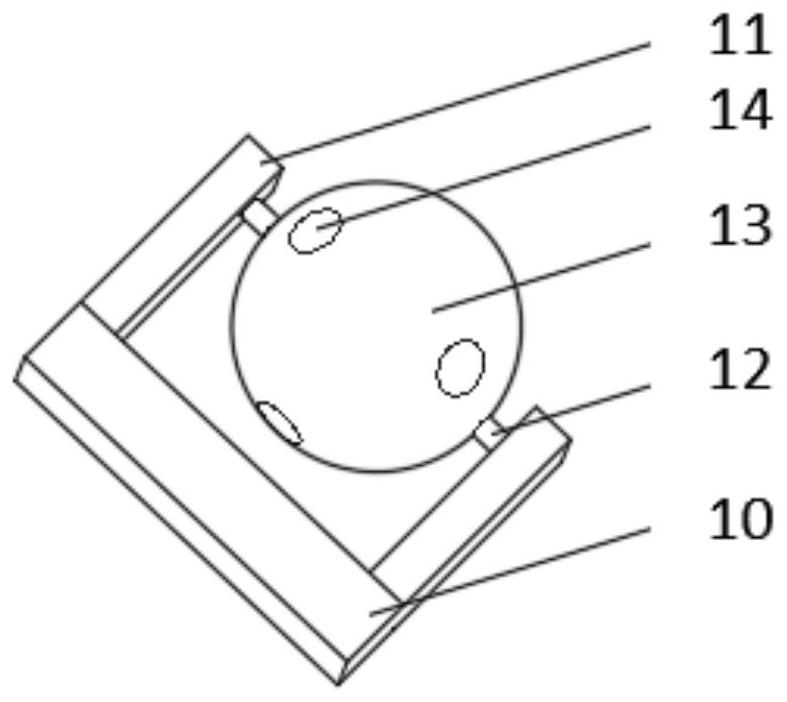

[0039] see Figure 1-5 , the present invention provides a technical solution: on the basis of the first embodiment, the inner wall of the groove 14 is symmetrically installed with a first limit block 15, and the inside of the groove 14 is equipped with an impact device 16, and the impact device 16 includes an impact block 161 One side of the impact block 161 is fixedly connected with a movable plate 162, and one side of the movable plate 162 is symmetrically installed with a second limit block 163, and the side of the movable plate 162 away from the impact block 161 is fixedly connected with a spring 164, and the spring 164 is away from the movable One end of the plate 162 is connected to the bottom of the groove 14 .

[0040] The inner wall of the groove 14 is symmetrically provided with a chute 20 away from the position of the first limiting block 15, and one end of the chute 20 is rotatably connected with a baffle 21, and the end of the baffle 21 away from the chute 20 is r...

Embodiment 3

[0044] see Figure 1-7 , the present invention provides a technical solution: on the basis of Embodiment 2, a support device 17 is installed inside the cleaning ball 13, the support device 17 includes a limit ball 171, and a support frame 172 is evenly installed on the outside of the limit ball 171, A cutter head 173 is installed on the outside of the support frame 172 , and a blade 174 is installed on one side of the cutter head 173 .

[0045] During use, the cleaning ball 13 squeezes the kitchen waste toward the inner frame 6, and the cleaning ball 13 is depressed to the inside of the support frame 172 by the extrusion force from the garbage. 172 exposes the surface of cleaning ball, and after the blade 174 that is installed on the support frame 172 fully contacts with rubbish, rubbish is cut, after cleaning ball 13 rotates with inner frame 6, the support frame 172 of depression is no longer with inner frame 6 Contact, the sunken cleaning ball 13 is not subject to extrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com