Special rotating disc for atomizer

A rotating disk and atomizer technology, applied in the field of atomizers, can solve the problems of the influence of atomizer operation on power plant production, the closed atomization disk is easy to agglomerate and block, and the atomization efficiency is low, so as to achieve good market competitiveness , The effect of processing a large amount of lime slurry and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

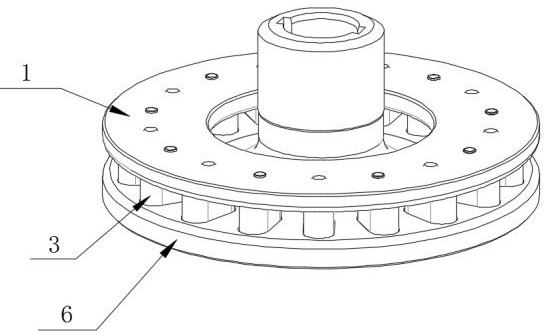

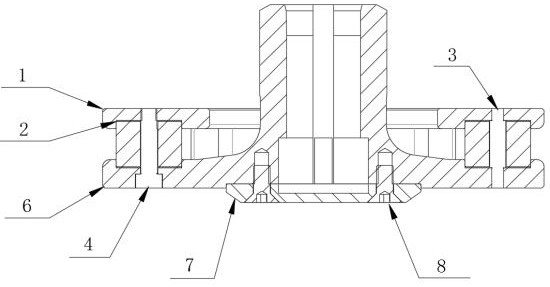

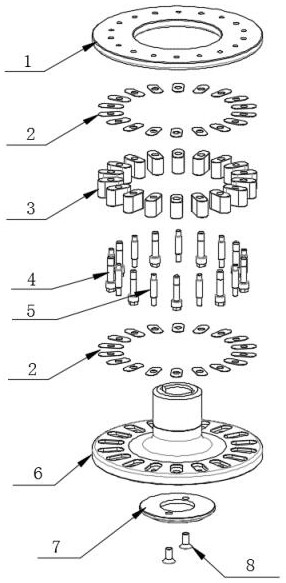

[0021] refer to Figure 1-7 , a special rotating disk for atomizers, including a top plate 1, a diverter block 3 is installed on the bottom of the top plate 1, and the diverter block 3 is fixed with positioning pins 5 and assembly bolts 4 respectively, which makes the fixing more convenient.

[0022] A plurality of gaskets 2 are installed on the top and bottom of the diverter block 3, and the plurality of gaskets 2 are fixedly connected with the top plate 1 and the chassis 6 at the corresponding positions, so that the installation is more convenient and the fixation is more stable.

[0023] The top plate 1 is fixedly connected with the diverter block 3, the interior ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com