Waste gas comprehensive purification process in feed processing industry

A technology of feed processing and purification technology, which is applied in the field of animal breeding and odorous gas comprehensive purification technology, can solve problems such as no targeted solutions, achieve efficient collaborative processing, ensure reliable operation, and operate with low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

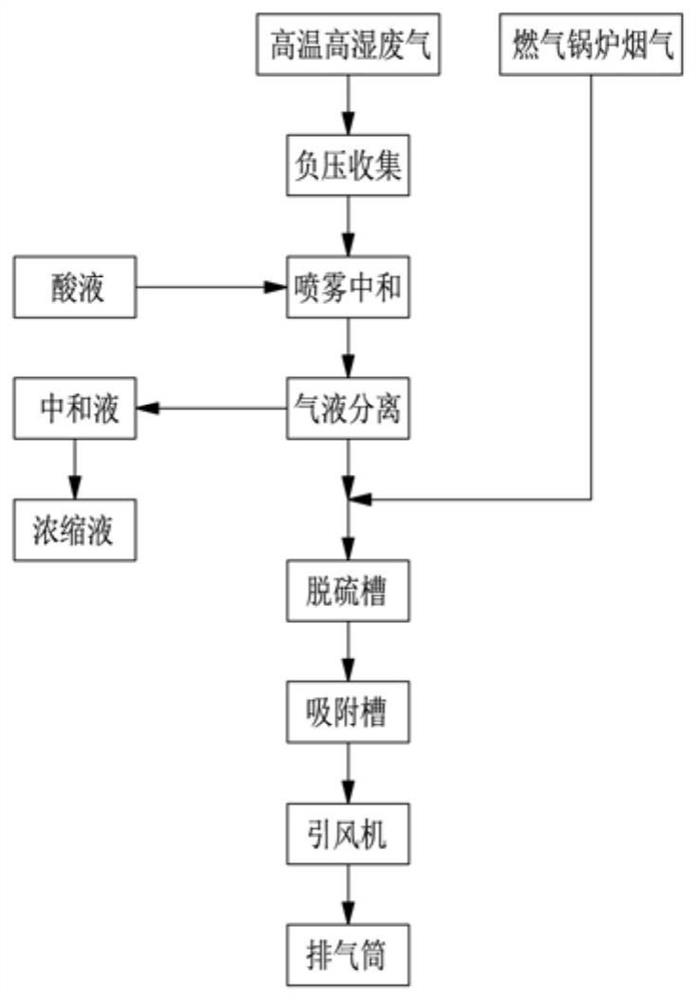

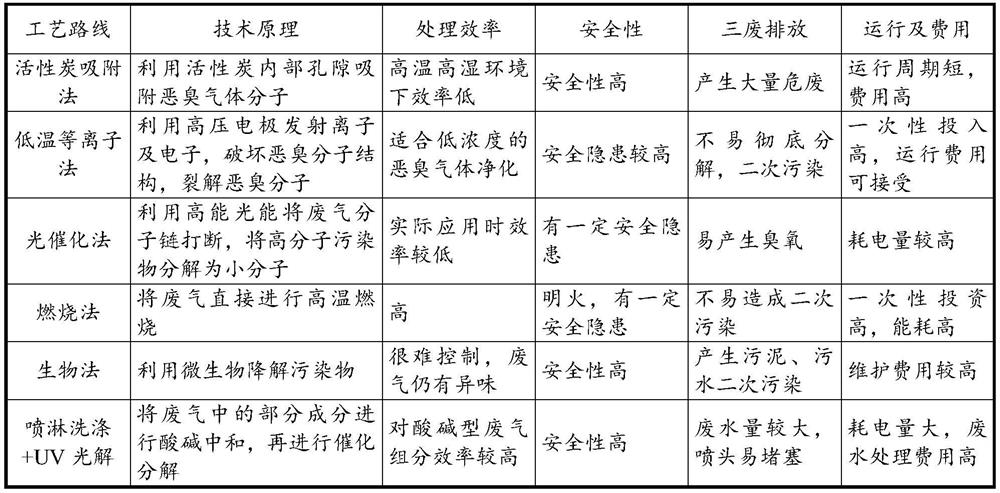

[0032] combine figure 1 As shown, an aquatic product workshop uses a large amount of fish meal and shrimp meal as raw materials to produce extruded feed, which produces a large amount of foul smelling gas, which seriously pollutes the site environment and surrounding residential areas. After collecting statistics, the exhaust gas emission is ~200,000m 3 / h, the temperature is 50-80°C, and the water vapor content is close to saturation. The operator reported that the intensity of the exhaust gas odor has reached an unbearable level, and the surrounding residents complained strongly. After analysis, the main odorous substances are trimethylamine, ammonia and hydrogen sulfide, and the initial concentration ranges from 1 to 50 mg / m 3 , The factory is equipped with a 4t / h gas-fired steam boiler, and the exhaust gas temperature of the boiler is ~150°C. After research, innovation and trial and error, the governance measures formulated are:

[0033] (1) Collect exhaust gas from al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com