Dry suspension containing oseltamivir phosphate and preparation method of dry suspension

A technology of oseltamivir phosphate and dry suspension, which is applied in the field of dry suspension containing oseltamivir phosphate and its preparation, can solve the problem that qualified preparations cannot be obtained smoothly, hydrophilic auxiliary materials are easy to form agglomerates, and the content Unqualified uniformity and other problems, to achieve the effect of easy granulation, good quality uniformity and reduction of batch differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

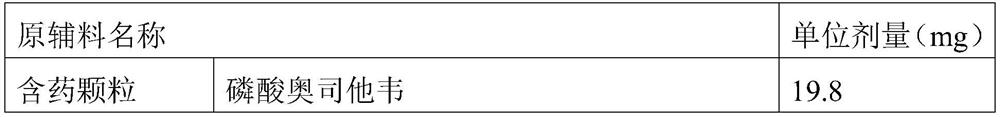

[0027]

[0028]

[0029] Preparation:

[0030] 1) dissolving the oseltamivir phosphate bulk drug in 40% ethanol to obtain a solution;

[0031] 2) Put the sorbitol, sodium benzoate, anhydrous monosodium citrate, and sodium saccharin in the drug-containing granules in a wet mixing granulator according to the ratio in the table and mix them for 5 minutes or more to obtain the drug-containing granules. Dry powder of granular excipients;

[0032] 3) Add the dry powder of drug-containing granules and auxiliary materials obtained in step 2 into the solid feeder, connect the solution obtained in step 1 with the extruder through a low-pulse peristaltic pump, and control the granulation temperature of the twin-screw extruder at 20-25 ℃, adjust the feeding speed of dry powder to 2.0-5.0kg / hr, the speed of peristaltic pump to 4rpm-10rpm, and the speed of twin-screw to 300rpm-600rpm; start feeding after discarding the material 5 minutes before extrusion to obtain wet granules;

[0...

Embodiment 2

[0041]

[0042] Preparation:

[0043] 1) Put the oseltamivir phosphate bulk drug, sorbitol, sodium benzoate, anhydrous monosodium citrate, and sodium saccharin in a wet mixing granulator and mix evenly;

[0044] 2) Add 40% ethanol water in step 1 to carry out wet granulation, set the stirring speed to 300rpm, and the shearing speed to 2000rpm; the obtained wet granules form agglomerates, and then pass through a sieve with an aperture of 1.0mm for 3 times;

[0045] 3) Put the wet granules in an oven and dry at 40-50°C for 2 hours to obtain dry granules;

[0046] 4) The dried granules are passed through a sieve with an aperture of 1.0mm for granulation,

[0047] 5) Sorbitol and titanium dioxide in the non-medicinal granules are placed in a mixing granulator and mixed evenly;

[0048]6) Add 40% ethanol water to step 5 to carry out wet granulation, set the stirring speed to 300rpm, and the shearing speed to 2000rpm; the obtained wet granules form agglomerates, and then pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com