Full-automatic online type continuous powder-liquid mixing and dispersing system

A technology of mixing system and dispersing system, which is applied in the field of fully automatic online continuous powder-liquid mixing and dispersing system, can solve the problems of slurry uniformity and stability, solvent instability, dust splashing, etc., and achieve the improvement of pulping Consistency, solve the effect of long mixing time and improve pulping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with specific embodiments:

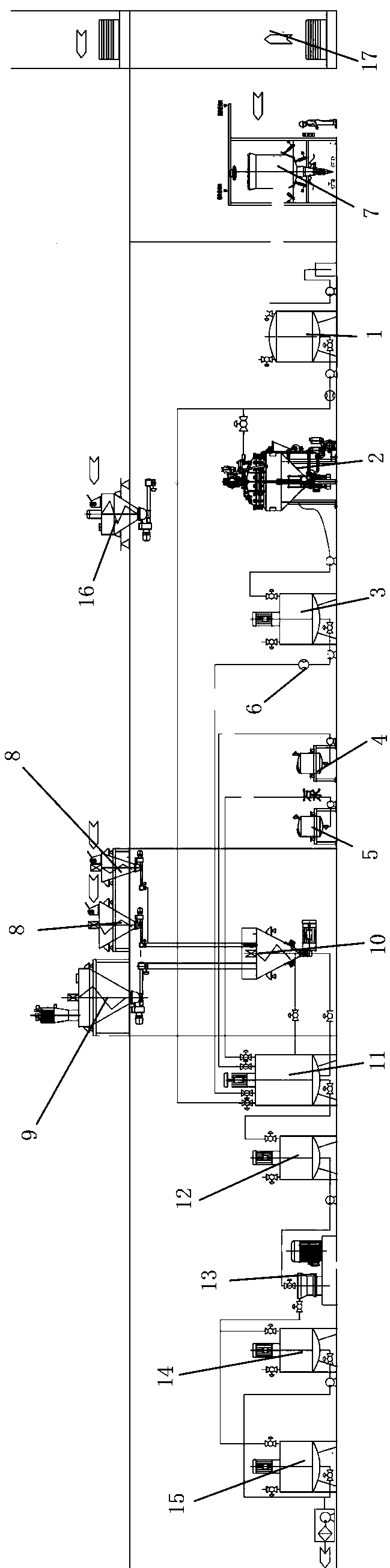

[0016] like figure 1 A fully automatic on-line continuous powder-liquid mixing and dispersing system shown, including a rubber production line, a powder supply line, a continuous powder-liquid mixing production line, a first metering tank 4, a second metering tank 5, and a continuous powder-liquid mixing system 11 , slurry buffer tank 12, high-speed dispersion system 13 and transfer tank 15;

[0017] The glue production line is composed of an NMP or aqueous solution storage tank 1, a glue preparation system 2, and a glue solution buffer tank 3 connected in sequence through pipelines, and a flow meter 6 is provided between the NMP or aqueous solution storage tank 1 and the glue preparation system 2. ;

[0018] The powder supply line is composed of a ton bag feeding station 7, a second auxiliary material tank 8, a vacuum feeder 9, and a premix tank 10. The mixing tank 10 perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com