Efficient brick tea production line

A production line and brick tea technology, which is applied in tea processing before extraction, food shaping, food science, etc., can solve the problems of mold waste time, overcooking of intermediate tea, and high humidity of tea leaves, so as to reduce export and loading times and overcome intermediate tea Effects of overripe, overdone and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

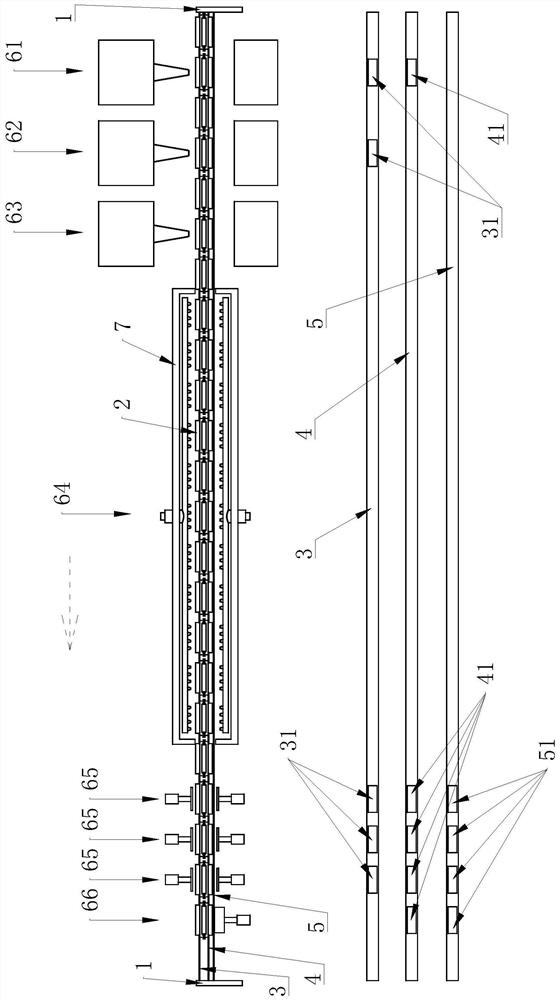

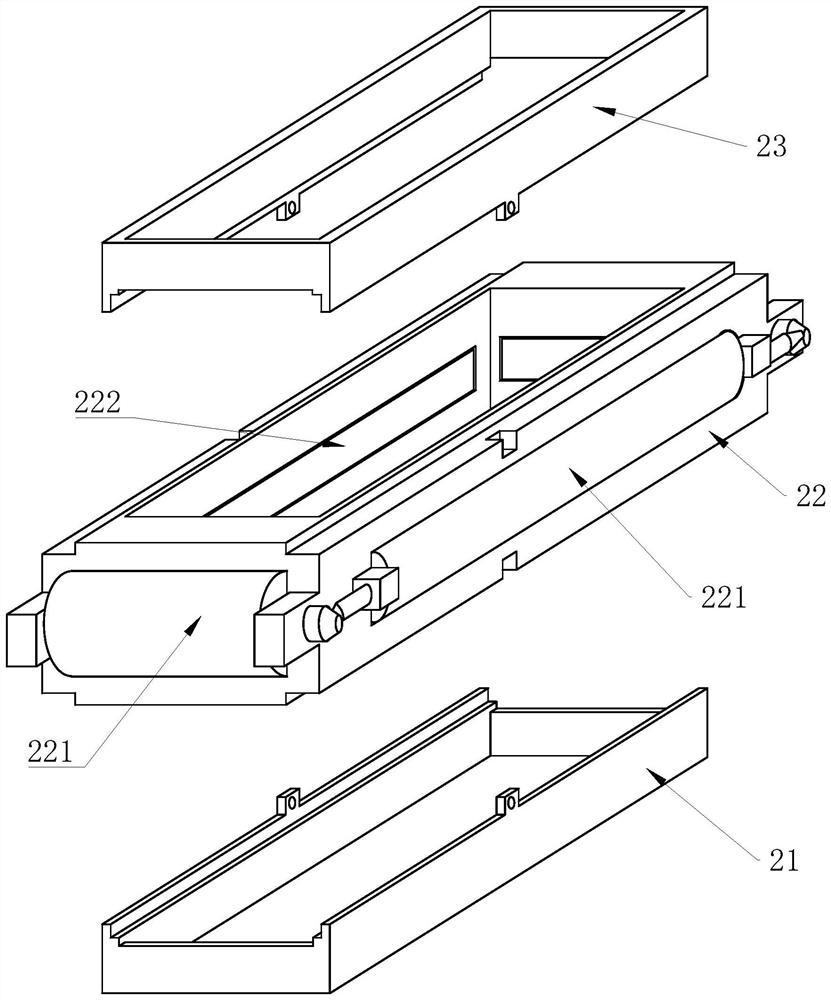

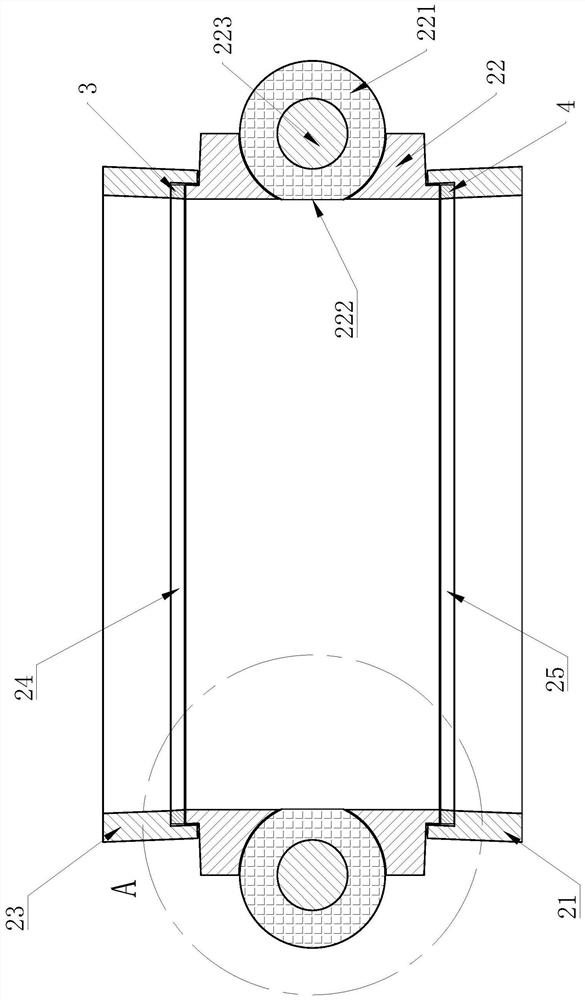

[0051] Such as Figure 1 to Figure 7 As shown, it includes two upright columns 1, several tea brick molds 2, a first guide plate 3 arranged horizontally and a second guide plate 4 parallel to the first guide plate 3, the two ends of the first guide plate 3 and the second guide plate 4 respectively fixed on two columns 1, the first guide plate 3 is located above the second guide plate 4; the second guide plate 4 is provided with a third guide plate 5 fixed on the two columns 1, the third guide plate 5 and The second guide plate 4 is parallel;

[0052] Each tea brick mold 2 is slidably connected on the first guide plate 3 and the second guide plate 4 to form a brick tea assembly line. The brick tea assembly line is successi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com