A chip packaging system

A packaging system and chip technology, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve problems such as parts not being put in in time, glue is not easy to apply, affecting packaging efficiency, etc. Forming efficiency, the effect of realizing packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] As a specific embodiment of the present invention, the edge of the air injection hole 19 is serrated, and the diameter of the bottom end of the air injection hole 19 is larger than the diameter of the top; the edge of the air injection hole 19 is serrated, and when the rubber protrusion 18 is pressed, Its air jet hole 19 can be deformed, because the edge of the air jet hole 19 is jagged, so its edge is subjected to the impact force of the extruded gas, and its edge is easily deformed, preventing the edge from being torn and causing the rubber protrusion 18 to be deformed. Damaged, and the diameter of the bottom end of the gas injection hole 19 is larger than the diameter of the top, so that the intensity of the ejected gas is higher, and the upward impact effect on the chip is better.

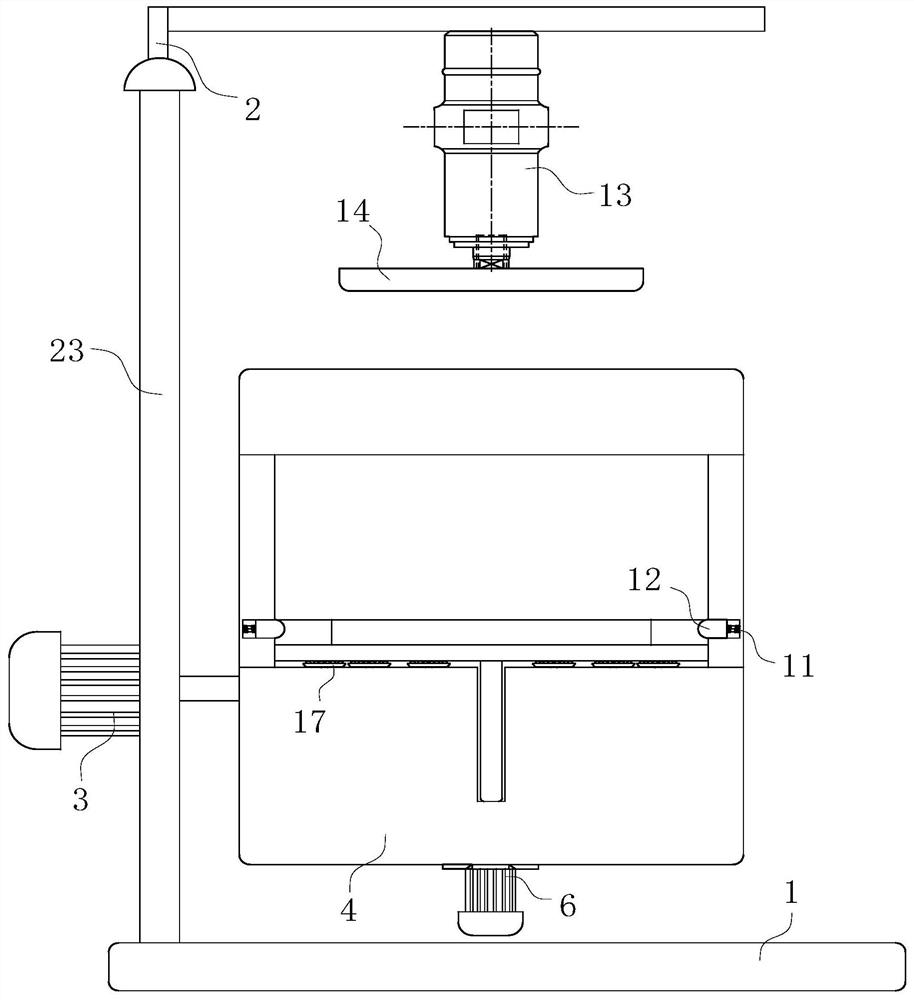

[0037] As a specific embodiment of the present invention, a gantry 23 is fixedly connected to the top of the base 1 close to the rear side, and the vertical plate 2 runs through the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com