A method of machining threaded steel bar transverse rib groove on roll

A threaded steel bar and roll technology, which is applied in the field of high-boron high-speed steel and small-sized threaded steel bar finished roll processing, can solve problems such as easy pause, low processing efficiency, and tailing, so as to reduce contact time, reduce processing costs, and ensure physical mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

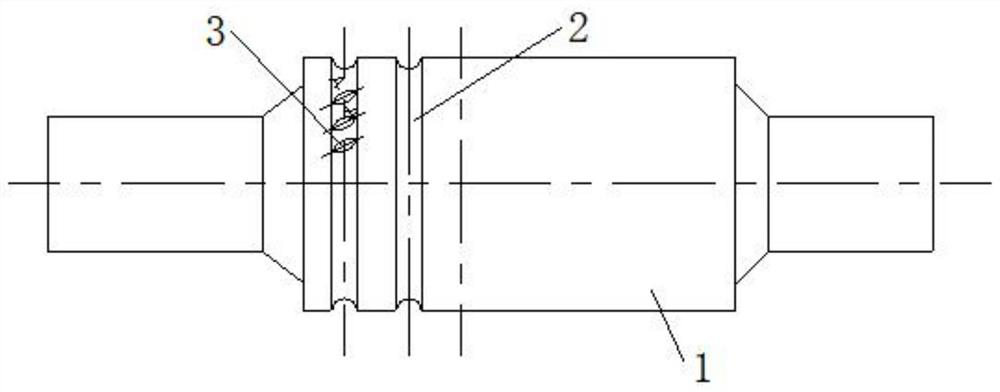

[0032] Such as figure 1 Shown, a kind of method for processing threaded bar transverse rib groove on roll, comprises the following steps:

[0033] S1. Before starting milling, leave a space of 30° to 60° before the milling cutter on the rotating cutter bar contacts the roll 1;

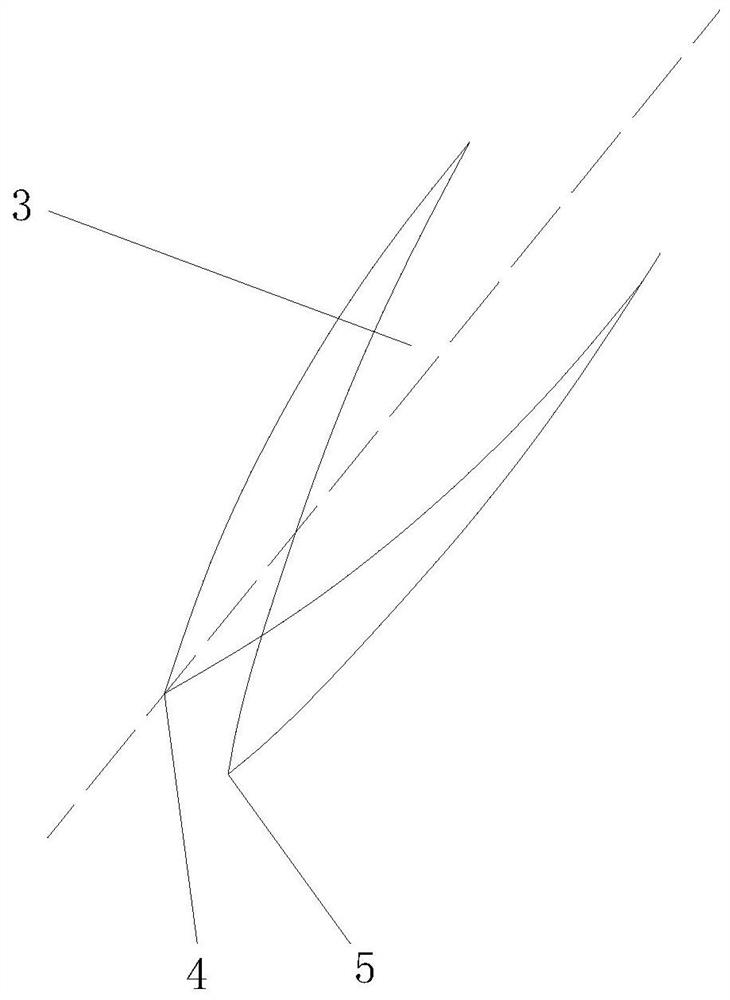

[0034] S2. During the milling process, the rotating cutter bar rotates 240°, so that the milling cutter forms a transverse rib groove 3 in the ring groove 2 of the roll 1;

[0035] S3. The rotary cutter bar continues to move the cutter 120°, and at the same time, the roll 1 rotates so that the next preset transverse rib groove 3 position corresponds to the milling position of the milling cutter;

[0036] S4. Step S2 and Step S3 are repeated until the machining of the transverse rib groove 3 in the annular groove 2 is completed.

[0037] The invention has high processing eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com