High-speed high-rigidity test bed

A test bench, high rigidity technology, applied in the direction of vehicle testing, automobile tire testing, machine/structural component testing, etc., can solve problems such as difficulty in ensuring distance accuracy, tire positioning deviation, vibration, etc., to ensure accurate testing The effect of ensuring the positioning stiffness and maintaining the relative position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present application will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the following illustrative examples and description are intended to be utilized to explain the present invention, and without conflict, the features and embodiments in the present application can be combined with each other. .

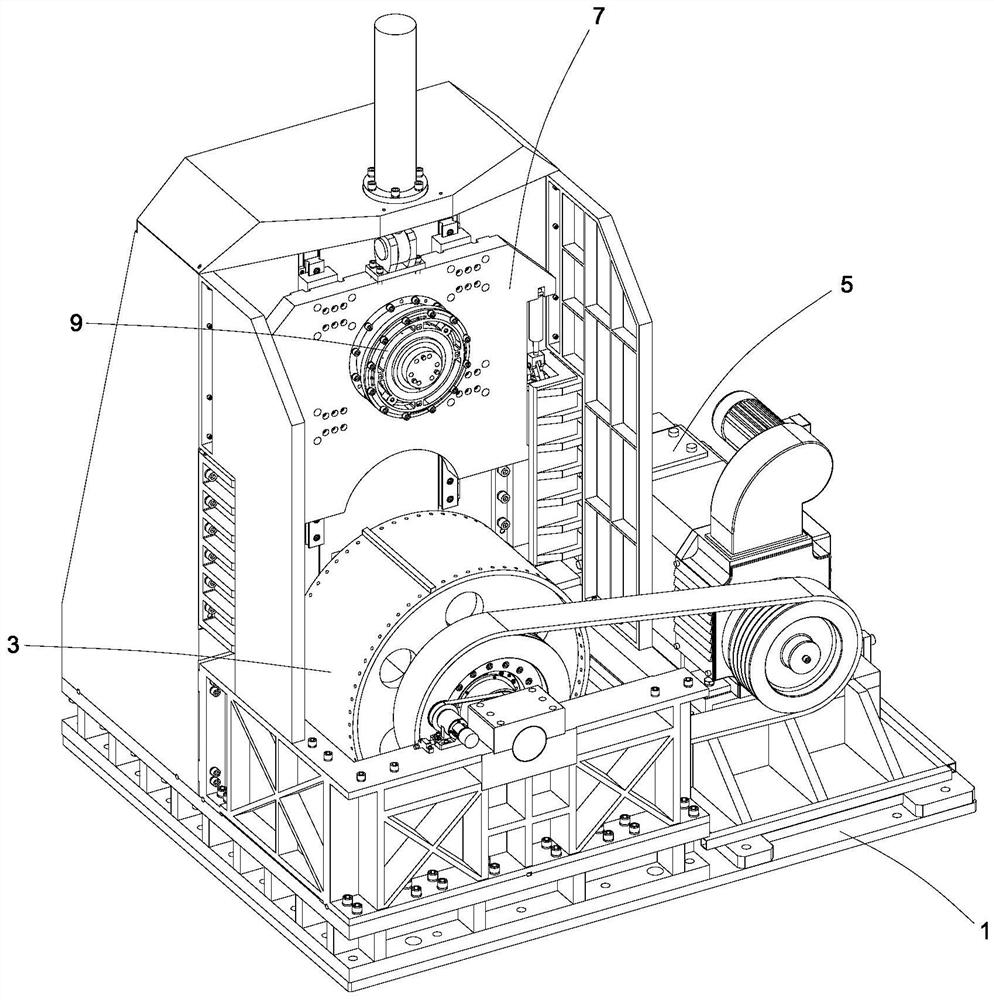

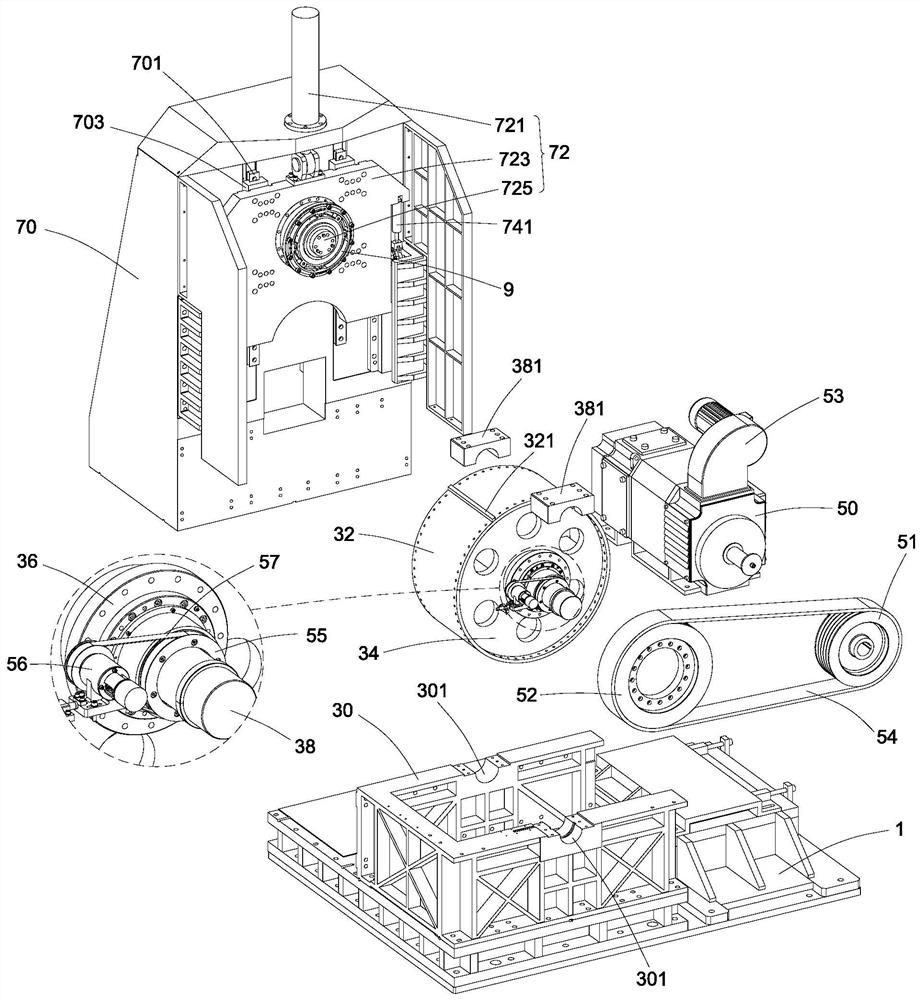

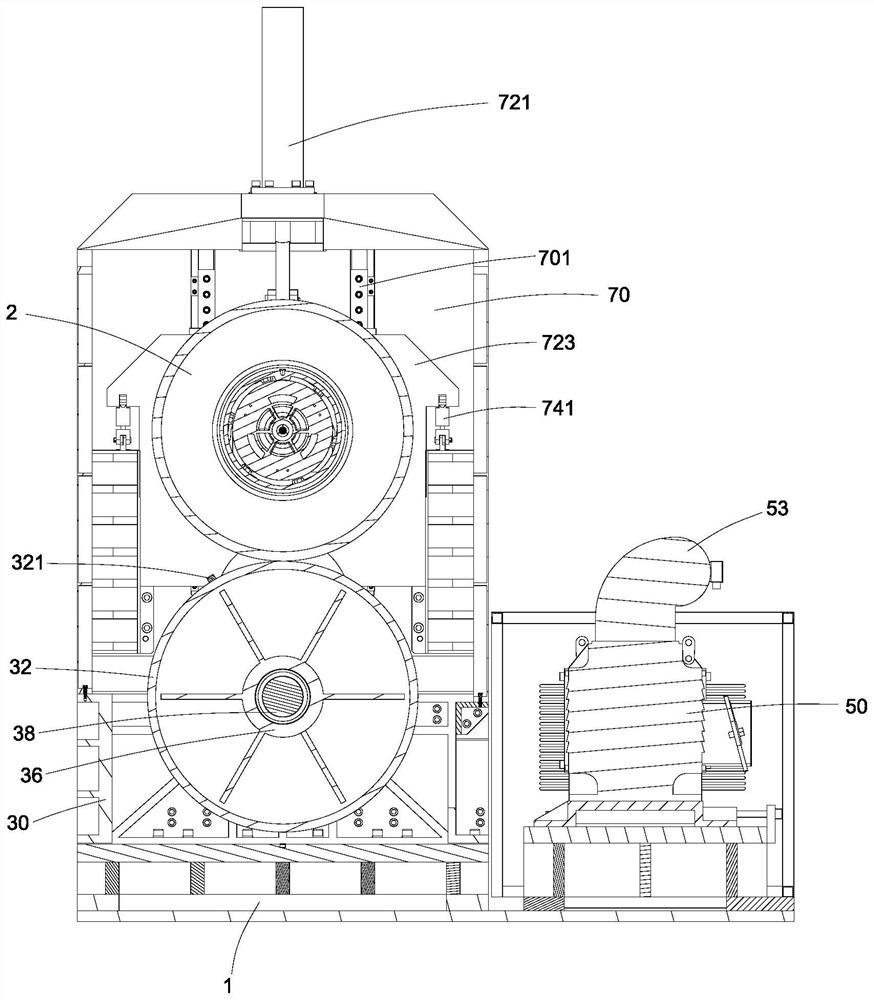

[0016] An alternative embodiment of the present invention provides a high-speed high stiffness test bench, such as Figure 1 - Figure 3 As shown, the test bench includes a base 1, a road surface analog mechanism 3 for an analog road supply tire 2 is mounted over the base 1 and is coupled to the channel simulation mechanism 3 for providing power to the road surface simulation. The drive mechanism 5 of the mechanism 3 includes a mounting frame 30, a drum 32 disposed inside the mounting frame 30, mounted on the inside of the drum 32, with the double-flap 34 The connected stabilizer 36 is app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com