Blade profile clamping device for machining of precision forging blade of aero-engine

An aero-engine and mechanical processing technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of long production cycle, clamping deformation, insufficient rigidity, etc., so as to solve the problem of non-deformation of blade torsion and ensure positioning Rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

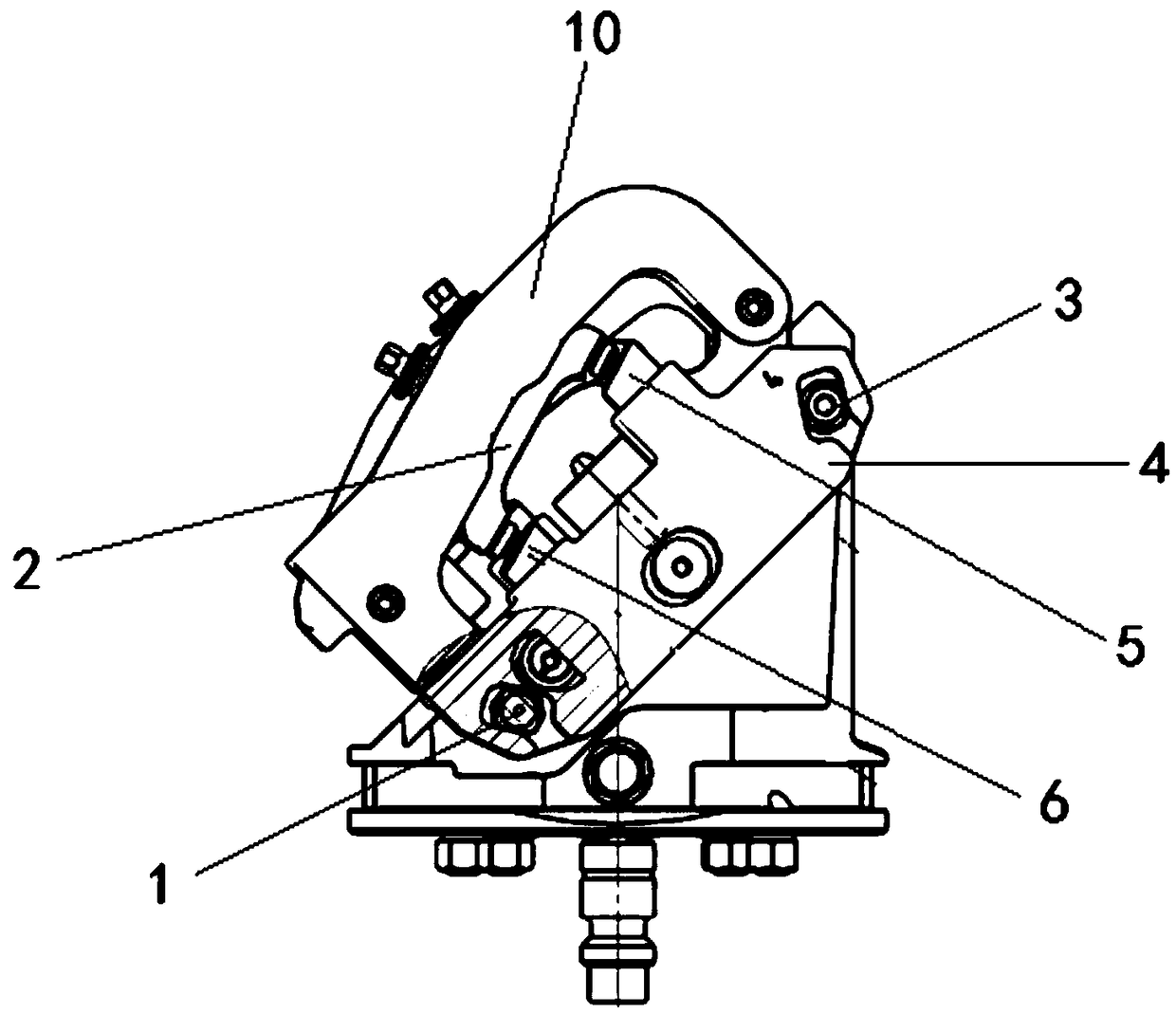

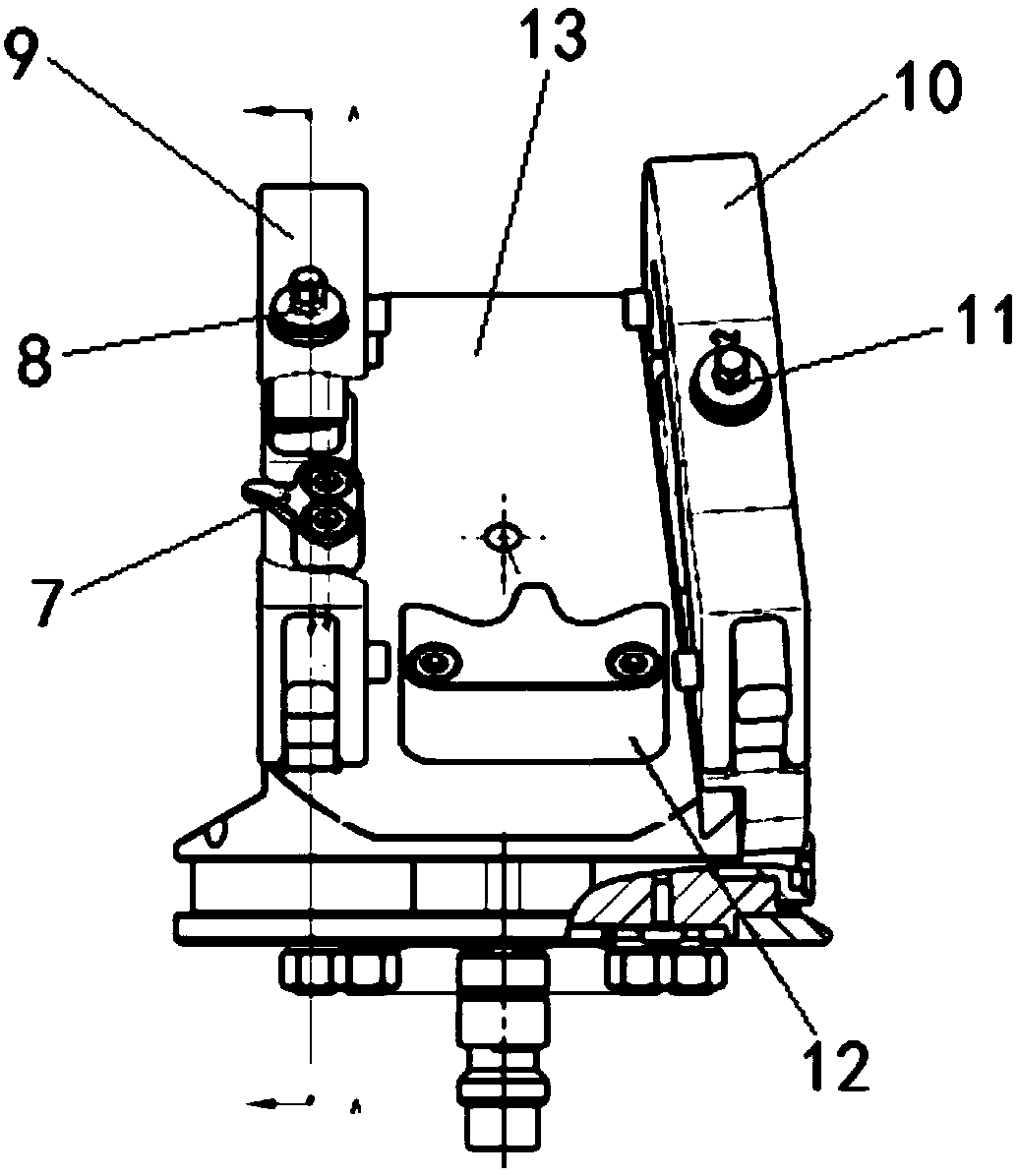

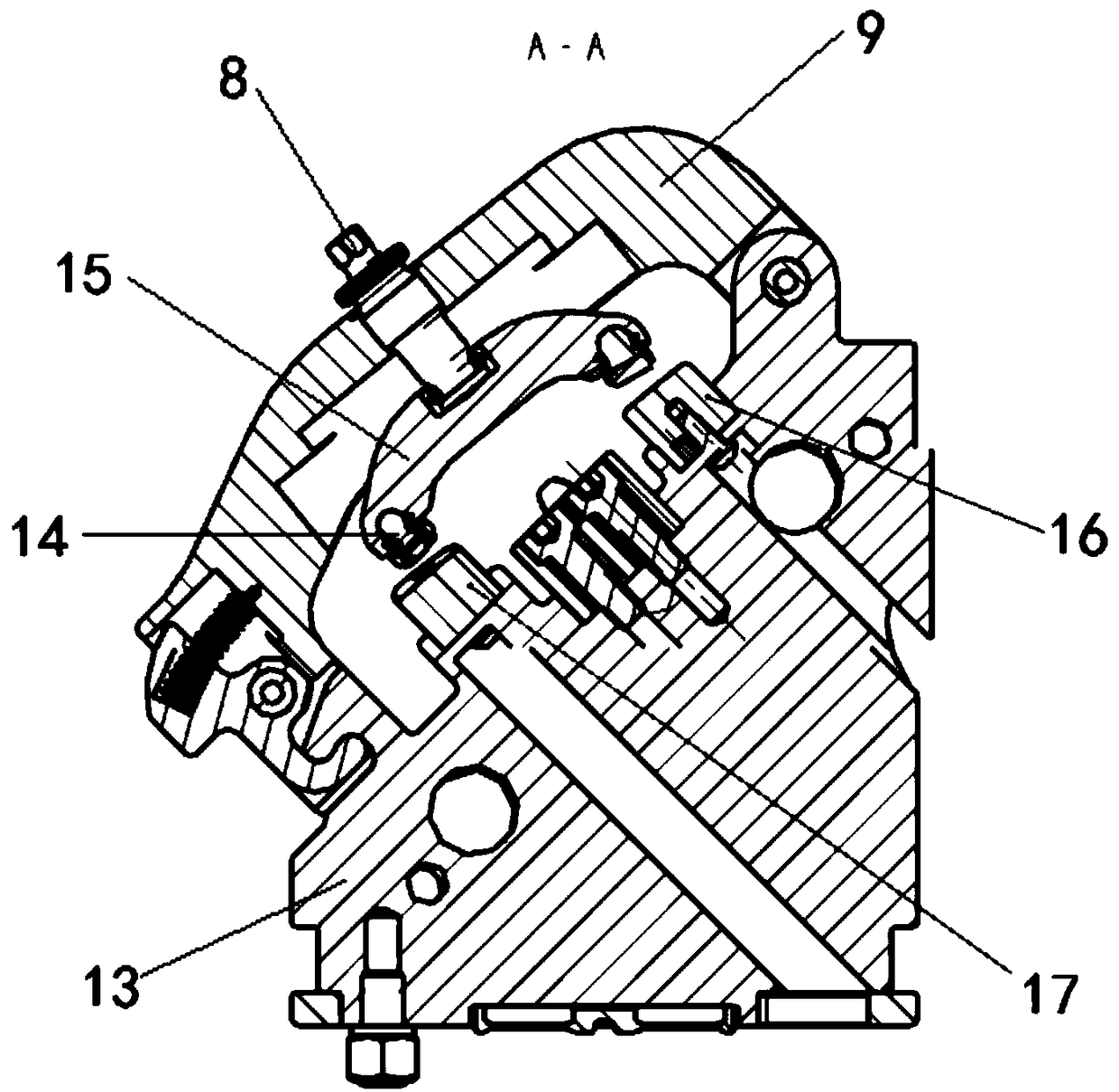

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0023] see Figure 1 to Figure 3 , an airfoil clamping device for the machining of precision forged blades of aero-engines, comprising a fixed clamping base 13, one side of the fixed clamping base 13 is connected to a movable clamping base 4 through a connecting shaft, and the movable clamping base 4 Can carry out slight rotation around the connecting shaft, the fixed clamping base 13 is movably connected with a first fixed pressing mechanism 9, one end of the first fixed pressing mechanism 9 is hinged on the fixed clamping base 13, and the other end is connected to the fixed clamping base 13 through a snap. The fixed clamping base 13 is connected, and the movable clamping base 4 is movably connected with a second fixed pressing mechanism 10. One end of the second fixed pressing mechanism 10 is hinged on the movable clamping base 4, and the other end is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com