Hydraulic tool

A tooling and hydraulic technology, applied in the field of hydraulic tooling, can solve the problems of low work efficiency, limited manual clamping and low efficiency, and achieve the effect of ensuring positioning rigidity, high drilling efficiency, and avoiding movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

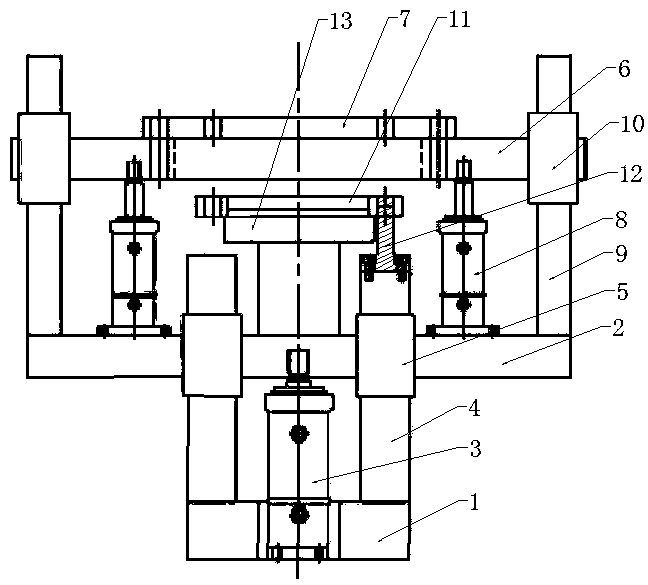

[0015] see figure 1 , a hydraulic tooling of the present invention, comprising a pressing mechanism and an upward mechanism, the upward mechanism comprises a base 1, a support 2 and a first oil cylinder 3, and both sides of the top of the base 1 are vertically fixed with a first guide column 4, The front end of the support 2 is vertically fixed with two first guide sleeves 5 corresponding to the first guide post 4, the first guide sleeve 5 is correspondingly sleeved on the first guide post 4, and the bottom end of the first oil cylinder 3 is fixed on the base 1 The middle part of the top, its top is fixedly connected with the middle part of the bottom end of the support 2, and the extension and contraction of the first oil cylinder 3 drive the support 2 to move up and down.

[0016] The pressing mechanism comprises a pressing plate 6, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com