Device and method for testing fatigue performance of round-link chain

A fatigue performance, circular chain technology, applied in the field of fatigue testing, can solve the problems of difficult to obtain accurate data, misalignment or deviation, low test success rate, etc., to improve the success rate and accuracy, flexible use, operation safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

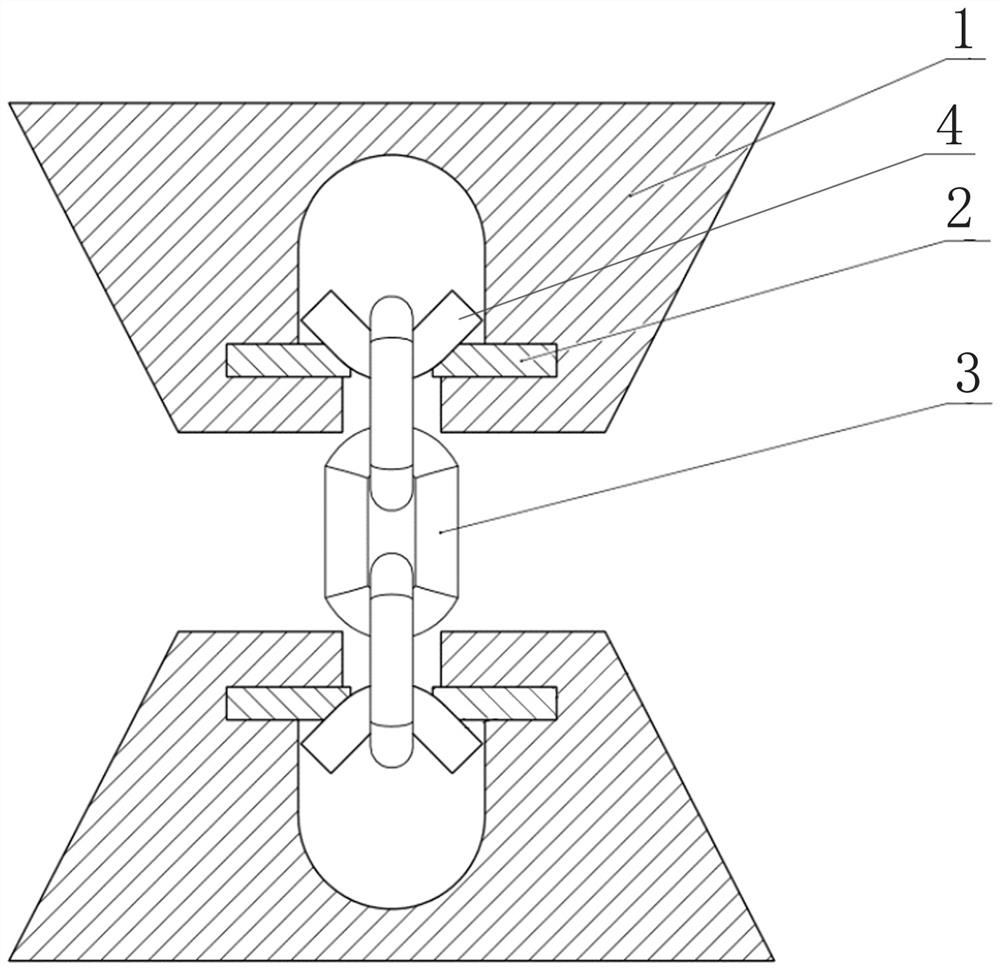

[0035] A method for detecting the fatigue performance of a circular link chain in embodiment one is achieved through the following steps:

[0036] A. The round link chain to be tested (3) is 10×40 in size and has a total length of 1m. According to the size of the round link chain (3), select a V-shaped card block with a diameter of 20mm (4 and the matching card plate (2 ;

[0037] B. According to the test requirements, determine the number of links of the round link chain (3;

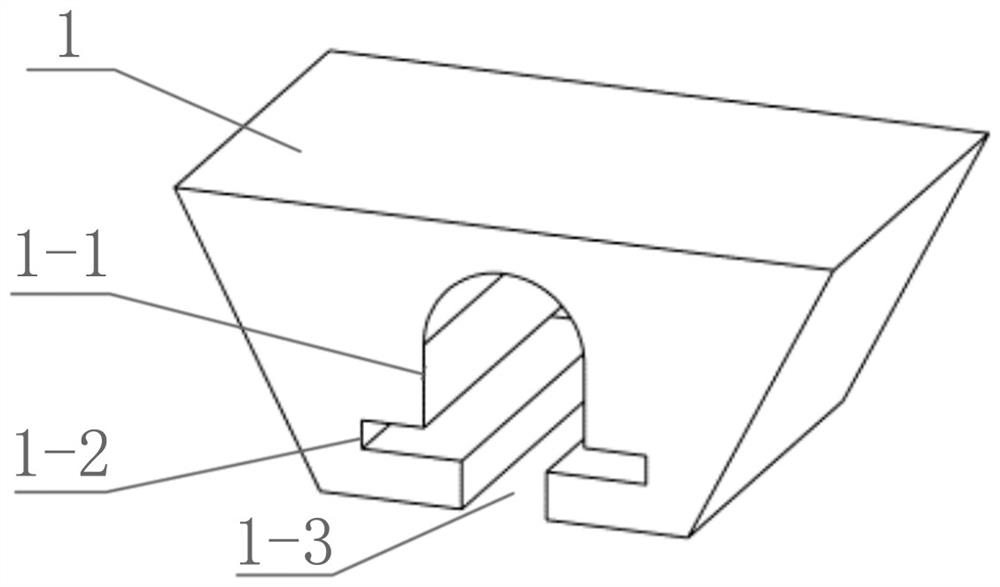

[0038] C. First place the two jaw seats 1 in the upper and lower beams of the hydraulic universal testing machine respectively, adjust the positions of the upper and lower beams to ensure that the two jaw seats 1 are centered and the distance matches the length of the circular link chain 3 to be tested;

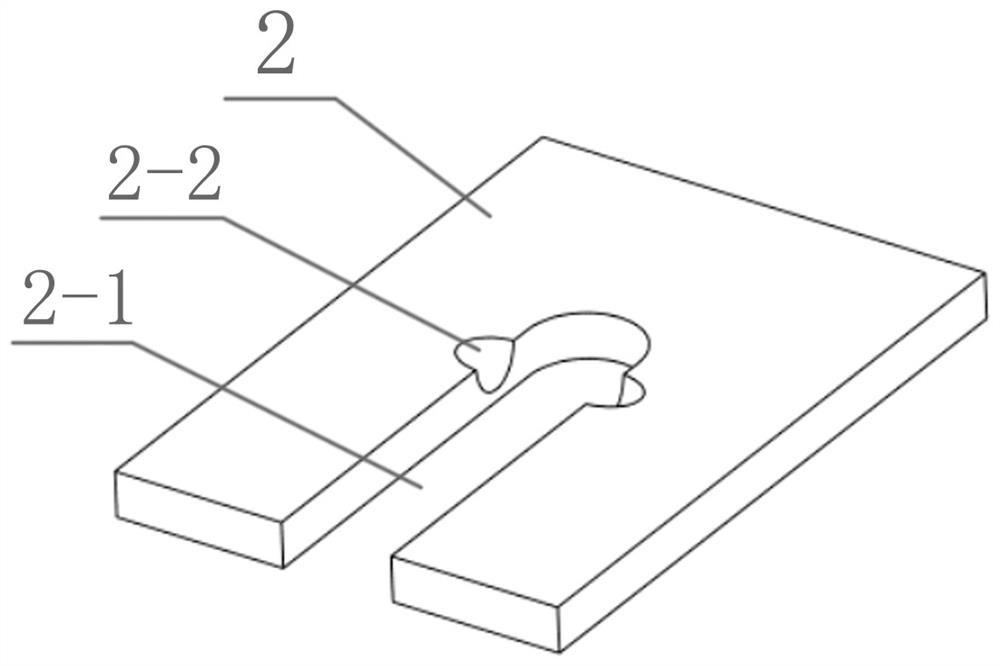

[0039] D. Insert the two clips 2 into the middle flat grooves 1-2 of the two jaw seats 1 respectively, so that the front and rear end faces of the clip 2 are flush with the front and rear end faces of...

Embodiment 2

[0044] A method for detecting the fatigue performance of a circular link chain in embodiment two is realized through the following steps:

[0045] A. The specification and model of the circular link chain 3 to be tested is 42×152, and the total length is 1.1m. According to the specification and model of the circular link chain 3, a V-shaped clamping block 4 with a diameter of 85mm and a clamping plate 2 of corresponding matching specifications are selected;

[0046] B, according to test requirement, determine the link quantity of circular link chain 3;

[0047] C. First place the two jaw seats 1 in the upper and lower beams of the hydraulic universal testing machine respectively, adjust the positions of the upper and lower beams to ensure that the two jaw seats 1 are centered and the distance matches the length of the circular link chain 3 to be tested;

[0048] D. Insert the two clips 2 into the middle flat grooves 1-2 of the two jaw seats 1 respectively, so that the front an...

Embodiment 3

[0053] A method for detecting the fatigue performance of a circular link chain in embodiment three is achieved through the following steps:

[0054] A. The specification and model of the circular link chain 3 to be tested is 26×92, and the total length is 1m. According to the specification and model of the circular link chain 3, a V-shaped clamp block 4 with a diameter of 55mm and a clamp plate 2 of corresponding matching specifications are selected;

[0055] B, according to test requirement, determine the link quantity of circular link chain 3;

[0056] C. First place the two jaw seats 1 in the upper and lower beams of the hydraulic universal testing machine respectively, adjust the positions of the upper and lower beams to ensure that the two jaw seats 1 are centered and the distance matches the length of the circular link chain 3 to be tested;

[0057] D. Insert the two clips 2 into the middle flat grooves 1-2 of the two jaw seats 1 respectively, so that the front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com