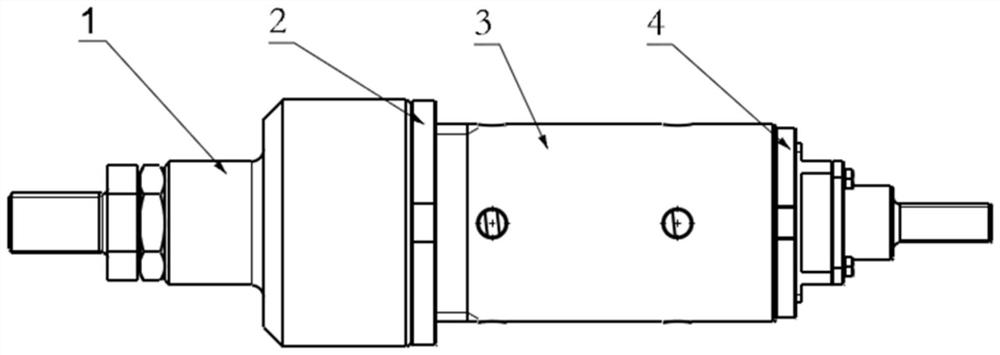

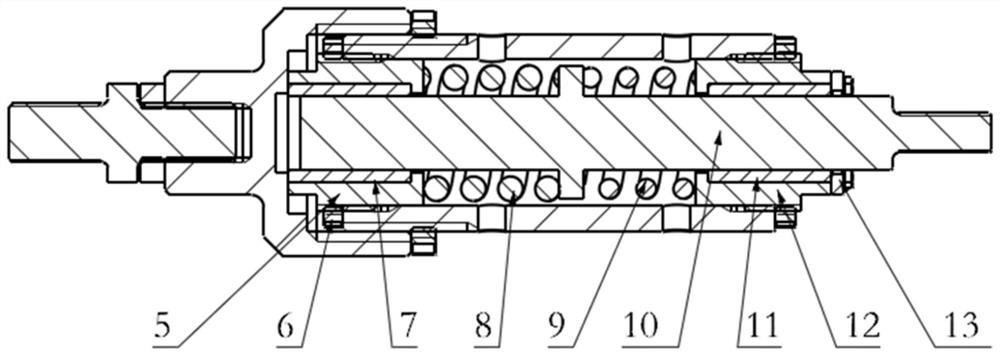

Asymmetric load buffer and parameter determination method

A buffer and asymmetric technology, applied in the field of aircraft strength test loading, can solve problems such as overrun stop, feedback and command error, poor loading response characteristics, etc., to avoid commutation impact, reduce stiffness, and ensure loading accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

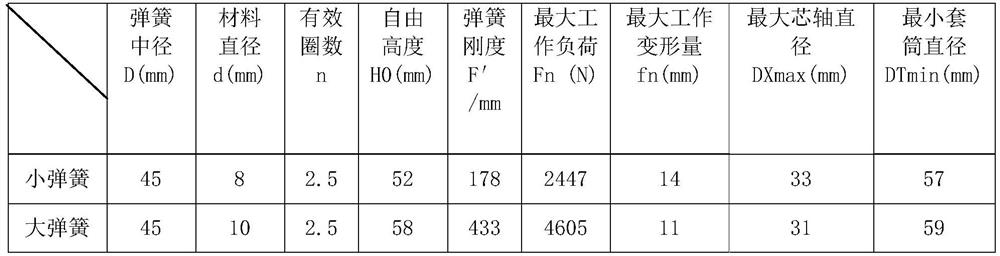

[0051] The actuator test loading stroke should be adjustable between 5mm-10mm, and the maximum tensile load is F 拉 =1530N, the maximum pressure load is F 压 =4630N. Determine the parameters of the spring according to the tension and compression load and the required deformation (see Table 1). During use, it is required that there should be no gap between the large spring and the small spring to ensure the continuity of the feedback load curve.

[0052] Table 1 Spring parameter table

[0053]

[0054] According to F 压 =4630N, when the large spring is compressed, the small spring is fully extended, and the compression amount of the large spring is f n =F 压 / F'=4630N / 433N / mm=10.7mm, when the spring is installed, the total compression of the two springs is 10.7mm. When the two springs are assembled and press against each other:

[0055] f 小 ’ X1=F 大 '·X2 and X1+X2=10.7

[0056] where F 小 '=178N / mm, F 大 ’=433N / mm

[0057] Obtain: X1=7.6mm, X2=3.1mm, that is, the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com