Oil inlet metering valve of split type cone valve structure and electric control fuel oil supply system

An oil inlet metering valve, split type technology, applied in the testing of machines/structural components, charging systems, measuring devices, etc., can solve the problem of low flow control accuracy of ball valves, poor stability of rail pressure fluctuations, and small fit gaps of slide valves, etc. problems, to achieve the effect of ensuring structural strength requirements, enhancing airtightness, and meeting airtightness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

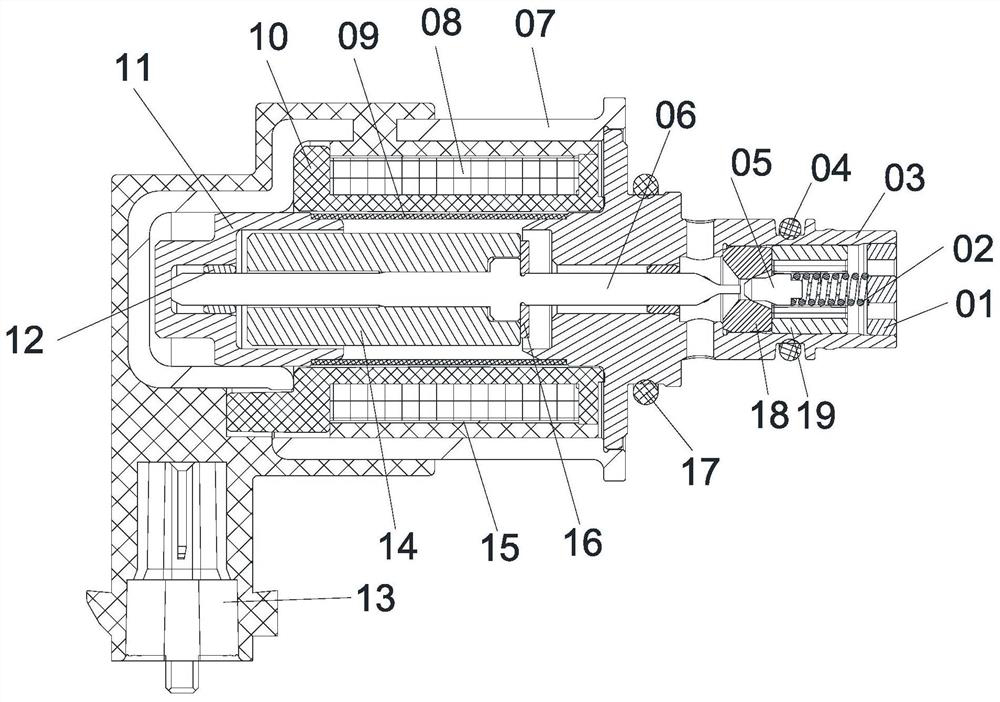

[0024] Such as figure 1 As shown, the oil inlet metering valve with a split poppet valve structure includes: a valve body assembly, the valve body assembly includes a valve body, a driving member and a flow control assembly, and the valve body is provided with an oil inlet and outlet valve. The valve body includes a valve cover 01, a pole shoe 03, a magnetic isolation ring 09 and a sleeve 11. One end of the pole shoe 03 is sealed by the valve cover 01, and the other end of the pole shoe 03 and the sleeve 11 are sealed by The magnetic isolation ring 09 is fixedly connected to form a closed space, the driving part and the flow control assembly are installed in the closed space, and the driving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com