Hydraulic punching coal-water-gas separator

A water-gas separator and hydraulic punching technology, applied in gas discharge, mining fluid, safety devices, etc., can solve problems such as coal-water turbulence, avoid gas overrun, improve the environment, and be beneficial to weighing analysis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

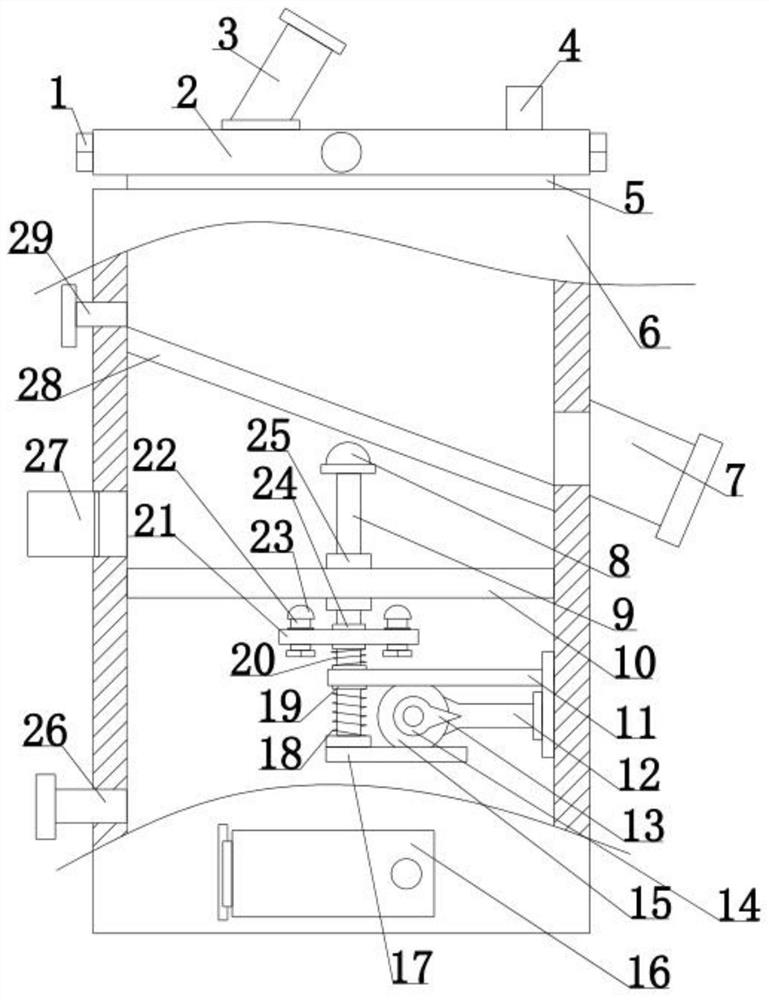

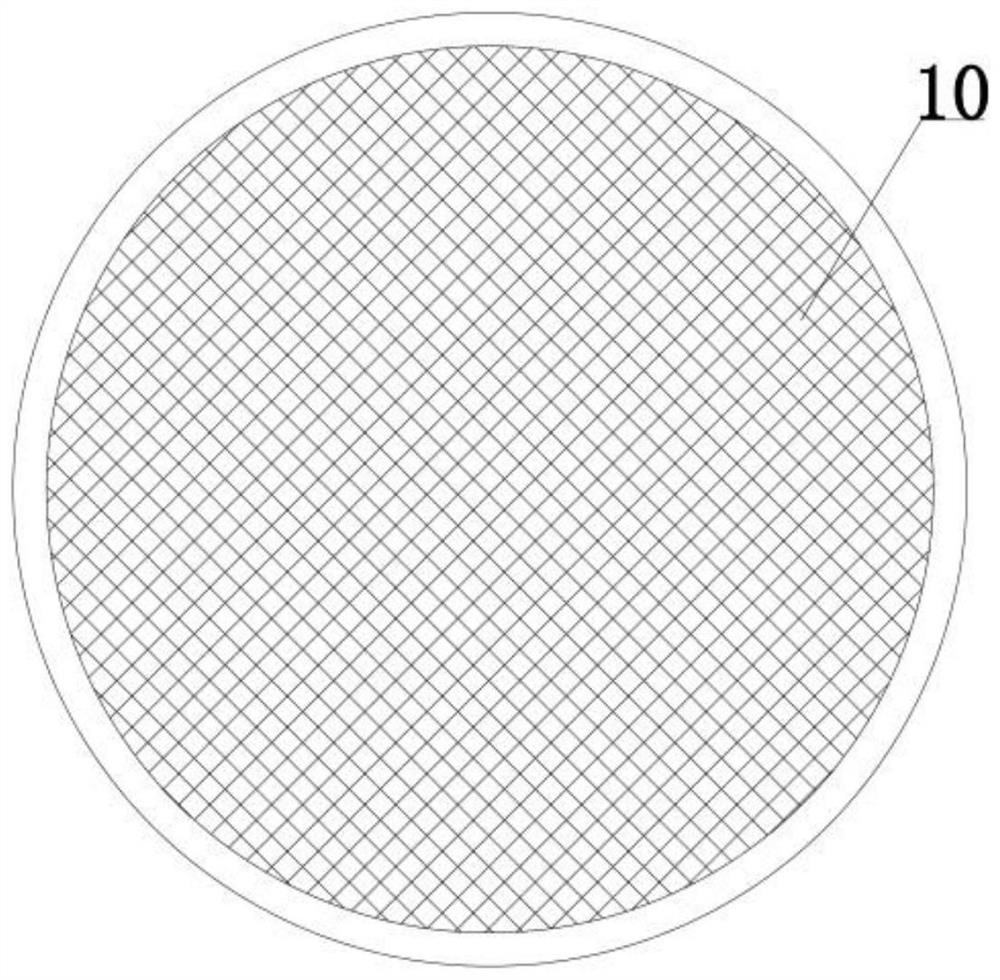

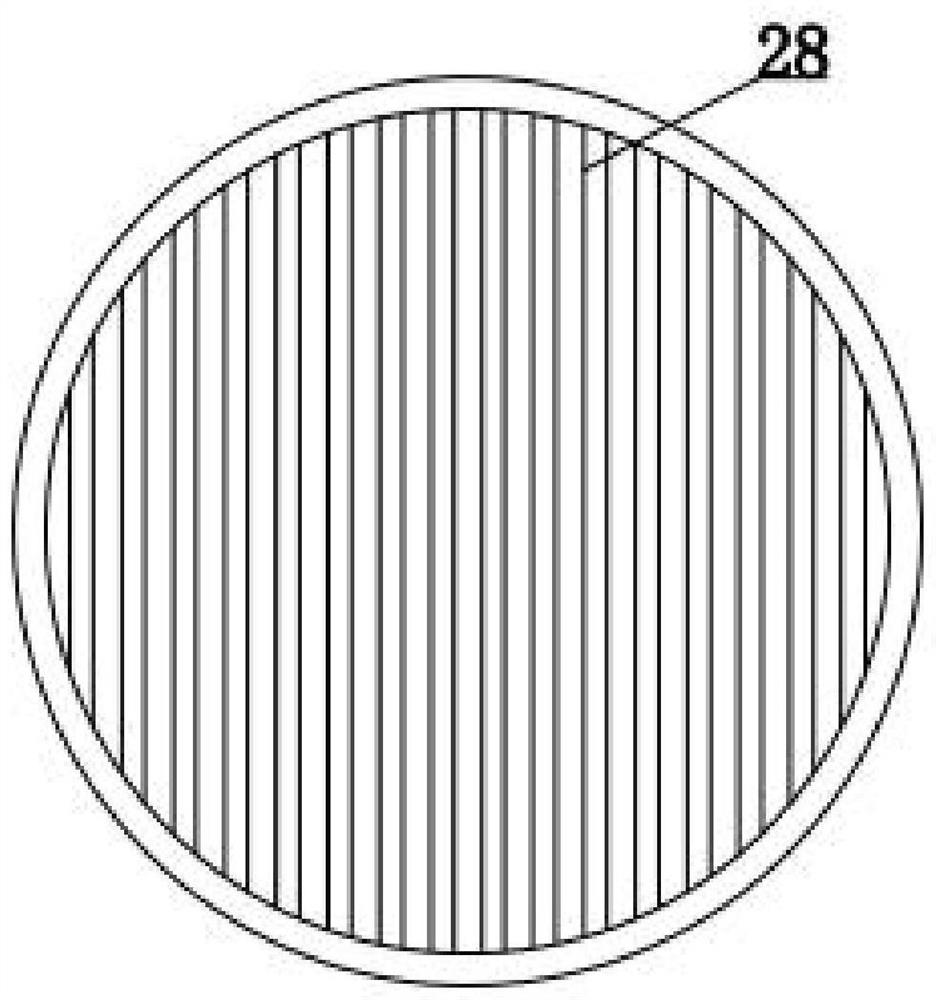

[0030] Such as Figure 1-3 As shown, the present embodiment provides an improved hydraulic punching coal-water gas separator, which mainly includes a separation barrel 6, a connection barrel 5 is fixedly installed on the upper side of the separation barrel 6, and a separation barrel cover 2 is installed on the top of the connection barrel 5. Between the barrel cover 2 and the connecting barrel 5, there are evenly installed barrel cover bolts 1, and the separation barrel cover 2 is fixedly installed with a water slag gas inlet 3 on the left side of the upper surface, and the gas outlet 4 is fixedly installed on the right side of the upper surface of the separation barrel cover 2. A water slag separation screen 28 is installed obliquely on the upper side of the bucket 6, and the left side of the water slag separation screen 28 is provided with an anti-blocking hole 29, and the right side of the water slag separation screen 28 is provided with a slag discharge port 7, and the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com