Rock-breaking method of cutter head based on space-time arrangement of oblique high-pressure water jet

A technology of high-pressure water jet and oblique cutting angle, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., to achieve the effects of low energy consumption, improved crushing efficiency, and reduced mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

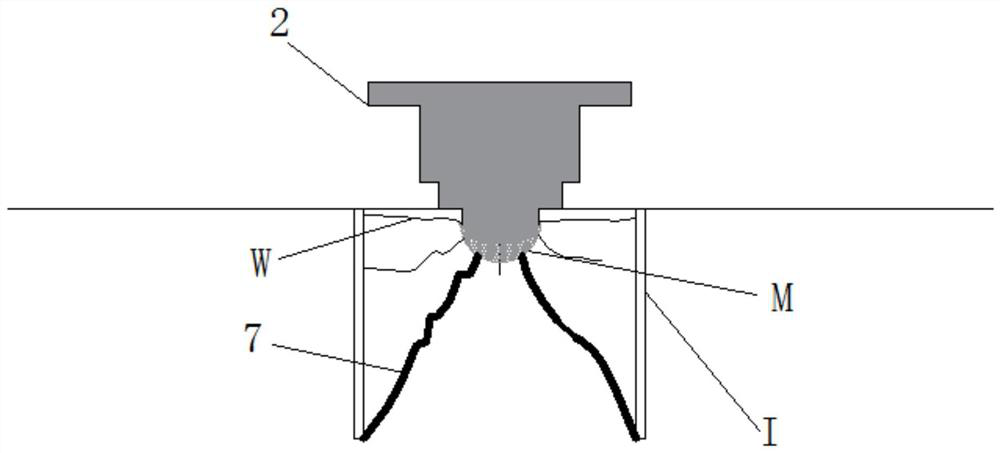

[0049] Referring to the accompanying drawings, it can be seen that the proposed rock-breaking method based on the cutter head arranged in time and space with the oblique angle high-pressure water jet is as follows: Figure 9 shown, including the following steps,

[0050] Step 1: high-pressure water jet beveling angle; use the high-pressure water jet sprayed by the No. 1 high-pressure water nozzle 1 in the cutterhead 9 based on the beveling angle high-pressure water jet spatio-temporal arrangement to cut grooves along a certain inclination angle on the rock mass material, Form the first inclined water cutting groove 6, make the local rock b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com