Clean production method of sheep shearlings for high-density bed blankets

A clean production, high-density technology, applied in application, leather drying, small raw hide/large raw hide/leather/fur treatment, etc., can solve the problem of limited hide use, reduced sorting rate, affecting raw hide application and production efficiency, etc. problem, to achieve the effect of enhancing convergence, solving the problem of gross density, and increasing the effect of fixed shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

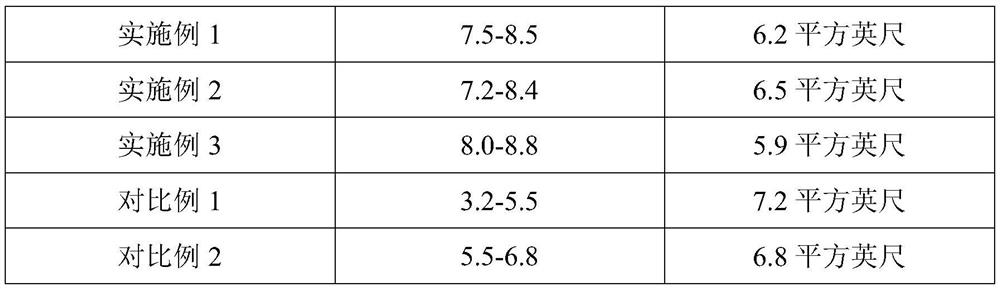

Embodiment 1

[0034] A clean production method of sheep shearling for high-density bed blankets, comprising the following steps:

[0035] 1) Skin washing, flesh removal, shearing; skin washing includes: water temperature 28 ℃, 40kg water per skin, add degreasing agent 2g / L and soda ash 0.5g / L, rotate for 60 minutes, stop for 55 minutes and rotate for 5 minutes method for 10 hours, drain and wash with 25°C water;

[0036] 2) Soaking in water, including: water temperature 26°C, 30kg water for 1 skin, adding 1g / L of immersion aid, 1g / L of degreasing agent, 0.4g / L of soda ash, 0.3g / L of fungicide, and turning for 30 minutes, then stop 25 minutes to 5 minutes to treat for 15 hours, drain and wash again;

[0037] 3) Degreasing, including: water temperature 38°C, 1 skin 30kg water, add degreasing agent 4g / L, soda ash 0.5g / L, rotate for 90 minutes, drain and wash once;

[0038] 4) Treatment for increasing gross density: add skins into the astringent tanning agent bath, stir evenly, and soak for 1...

Embodiment 2

[0045] A clean production method of sheep shearling for high-density bed blankets, comprising the following steps:

[0046] 1) Skin washing, flesh removal, shearing; skin washing includes: water temperature 28°C, 1 skin 40kg water, add degreasing agent 4g / L and soda ash 1.5g / L, rotate for 60 minutes, stop for 55 minutes and turn for 5 minutes Method for 8 hours, drain, and wash with 25°C water;

[0047] 2) Soaking in water, including: water temperature 26°C, 30kg water for 1 skin, adding 2g / L of immersion aid, 3g / L of degreasing agent, 0.4g / L of soda ash, 0.3g / L of fungicide, and turning for 30 minutes to stop 25 minutes to 5 minutes for 10 hours, drain and wash again;

[0048] 3) Degreasing, including: water temperature 38°C, 1 skin 30kg water, add degreasing agent 2g / L, soda ash 0.5g / L, rotate for 90 minutes, drain and wash once;

[0049] 4) Treatment for increasing gross density: add skins into the astringent tanning agent bath, stir evenly, and soak for 15 hours; the pre...

Embodiment 3

[0056] A clean production method of sheep shearling for high-density bed blankets, comprising the following steps:

[0057] 1) Skin washing, flesh removal, shearing; skin washing includes: water temperature 28°C, 1 skin 40kg water, add degreasing agent 2.5g / L and soda ash 0.8g / L, rotate for 60 minutes, stop for 55 minutes and rotate for 5 minutes 8 hours, drain and wash with 25°C water;

[0058] 2) Soaking in water, including: water temperature 26°C, 30kg water for 1 skin, adding 1.5g / L immersion aid, 2g / L degreasing agent, 0.4g / L soda ash, 0.3g / L fungicide, after 30 minutes of rotation, with Stop for 25 minutes and turn for 5 minutes to treat for 12 hours, drain and wash again;

[0059] 3) Degreasing, including: water temperature 38°C, 30kg water for 1 piece of skin, add 2.5g / L degreasing agent, 0.5g / L soda ash, rotate for 90 minutes, drain and wash once;

[0060] 4) Treatment for increasing gross density: add skins into the astringent tanning agent bath, stir evenly, and soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com