Method for controlling formaldehyde release rate by controlling moisture content of artificial board

A wood-based panel and anti-formaldehyde technology, applied in biocide-containing paints, anti-fouling/underwater coatings, devices for coating liquids on the surface, etc., can solve problems such as low timeliness and instability, and achieve material stability, Easy to use, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An anti-formaldehyde paint for wood-based panels, comprising the following components in parts by weight, a leveling agent, a penetrating agent, a hydrophobic agent, carbomer 940 resin, a curing agent, and deionized water.

[0037] The formaldehyde-resistant coating is prepared by mixing at normal temperature and pressure.

[0038] Meanwhile, the hydrophobic agent includes any one of potassium methyl silicate, sodium methyl silicate, and fluorinated polyurethane.

[0039] Furthermore, the leveling agent is polyurethane.

[0040] Moreover, the penetrating agent includes any one of sodium salt of alkyl alcohol sulfate and sodium salt of alkylsulfonic acid.

[0041] The curing agent includes any one of dipropylene glycol methyl ether and dipropylene glycol butyl ether.

[0042] When preparing, first add the leveling agent, penetrating agent, and hydrophobic agent into container A, and mix them thoroughly by stirring the raw materials, then add the resin and curing agent ...

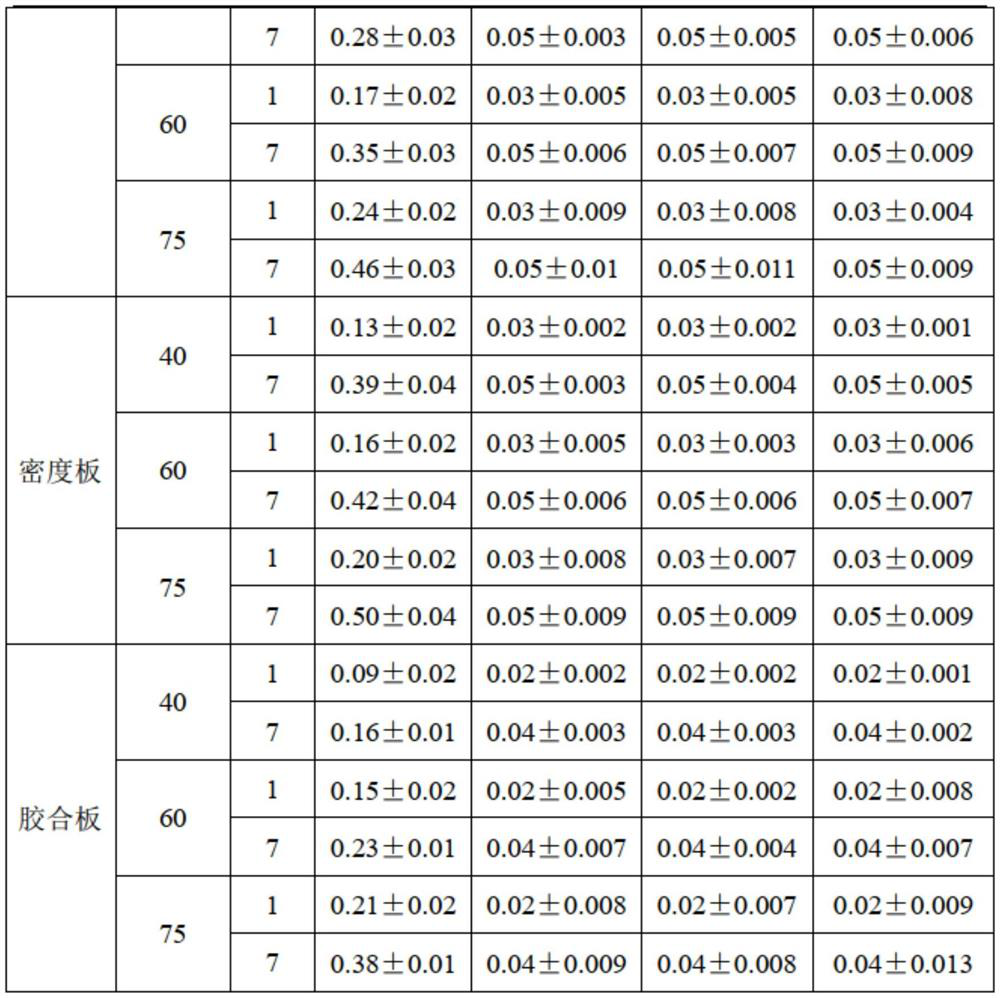

experiment example 1

[0046]In this experimental example, the raw materials are mixed according to the following parts by weight, 5 parts of polyurethane, 5 parts of sodium alkyl alcohol sulfate or sodium alkyl sulfonate, potassium methyl silicate or sodium methyl silicate or fluorinated polyurethane 10 parts of medium, 5 parts of carbomer 940 resin, 5 parts of dipropylene glycol methyl ether or dipropylene glycol butyl ether, and 950 parts of deionized water.

[0047] The aforementioned paint was coated on a wood-based panel as a sample.

experiment example 2

[0049] In this experimental example, the raw materials were mixed according to the following parts by weight: 12 parts of polyurethane, 20 parts of sodium alkyl alcohol sulfate or sodium alkyl sulfonate, potassium methyl silicate or sodium methyl silicate or fluorinated polyurethane 27 parts of medium, 50 parts of carbomer 940 resin, 25 parts of dipropylene glycol methyl ether or dipropylene glycol butyl ether, and 850 parts of deionized water.

[0050] The aforementioned paint was coated on a wood-based panel as a sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com