Water-based ink composition and preparation method thereof

A composition and ink technology, applied in chemical instruments and methods, inks, mixers, etc., can solve the problems of unclear effect, impurity discharge, dull red printing color, etc., achieve clear printing effect, prevent foaming, promote water flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

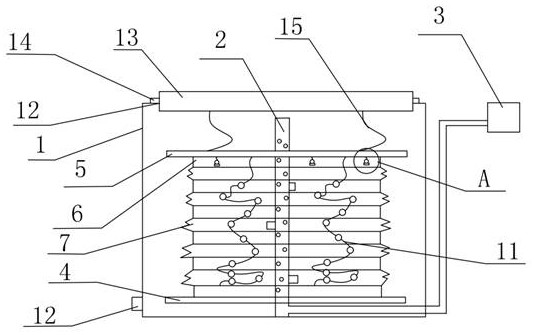

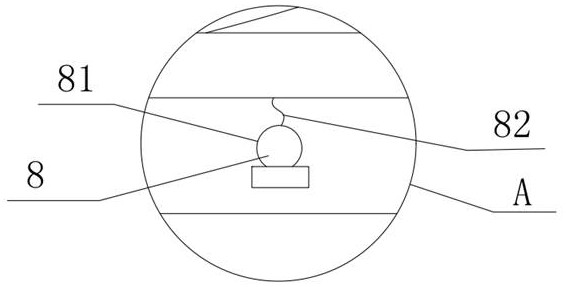

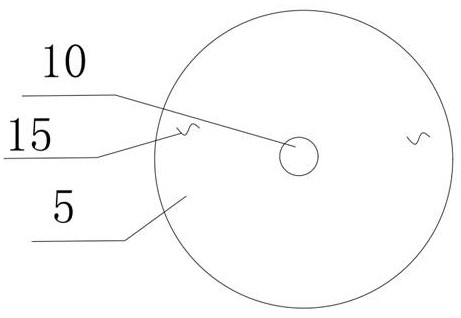

Method used

Image

Examples

Embodiment 1

[0025] A water-based ink composition, consisting of the following parts by weight: 5 parts of styrene resin, 7 parts of quinacridone, 2 parts of nano-SiC, and nano-TiO 2 10 parts, maleic anhydride 3 parts, polyurethane emulsion 5 parts, propylene glycol 3 parts, ethylene glycol butyl ether 2 parts, polyether trisiloxane 0.8 parts, triarylsulfonium salt 1.5 parts, benzoin isopropyl ether 0.5 parts , 1 part of dipropylene glycol ether, 7 parts of active red, and 15 parts of deionized water.

[0026] Further, the particle size of the nano-SiC is 20nm, and the nano-TiO 2 The particle size of the polyurethane emulsion is 20nm; the solid content of the polyurethane emulsion is 40%, and the viscosity: 40 mpa·s.

[0027] A method for preparing the described aqueous ink composition, consisting of the following steps: styrene resin, quinacridone, nano-SiC, nano-TiO 2 , maleic anhydride, polyurethane emulsion, propylene glycol, ethylene glycol butyl ether, polyether trisiloxane, triary...

Embodiment 2

[0037] A water-based ink composition, consisting of the following parts by weight: 7 parts of styrene resin, 8 parts of quinacridone, 2.5 parts of nano-SiC, and nano-TiO 2 12 parts, maleic anhydride 5 parts, polyurethane emulsion 7 parts, propylene glycol 4 parts, ethylene glycol butyl ether 2.5 parts, polyether trisiloxane 1 part, triarylsulfonium salt 2 parts, benzoin isopropyl ether 1 part , 1.5 parts of dipropylene glycol ether, 8 parts of reactive red, and 18 parts of deionized water.

[0038] Further, the particle size of the nano-SiC is 25nm, and the nano-TiO 2 The particle size of the polyurethane emulsion is 25nm; the solid content of the polyurethane emulsion is 45%, and the viscosity: 50 mpa·s.

[0039] A method for preparing the described aqueous ink composition, consisting of the following steps: styrene resin, quinacridone, nano-SiC, nano-TiO 2 , maleic anhydride, polyurethane emulsion, propylene glycol, ethylene glycol butyl ether, polyether trisiloxane, triaryl...

Embodiment 3

[0041] A water-based ink composition, consisting of the following parts by weight: 8 parts of styrene resin, 10 parts of quinacridone, 3 parts of nano-SiC, and nano-TiO 2 15 parts, maleic anhydride 6 parts, polyurethane emulsion 8 parts, propylene glycol 5 parts, ethylene glycol butyl ether 3 parts, polyether trisiloxane 1.5 parts, triarylsulfonium salt 2.5 parts, benzoin isopropyl ether 1.5 parts , 2 parts of dipropylene glycol ether, 10 parts of reactive red, and 20 parts of deionized water.

[0042] Further, the particle size of the nano-SiC is 30nm, and the nano-TiO 2 The particle size of the polyurethane emulsion is 30nm; the solid content of the polyurethane emulsion is 50%, and the viscosity is 70 mpa·s.

[0043] A method for preparing the described aqueous ink composition, consisting of the following steps: styrene resin, quinacridone, nano-SiC, nano-TiO 2 , maleic anhydride, polyurethane emulsion, propylene glycol, ethylene glycol butyl ether, polyether trisiloxane,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com