Method for treating sucralose primary mother liquor

A technology for sucralose and processing methods, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve problems affecting product quality, abnormal taste of sugar water, poor extraction and removal of impurities, etc., and improve the extraction effect , Improve product quality, improve the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

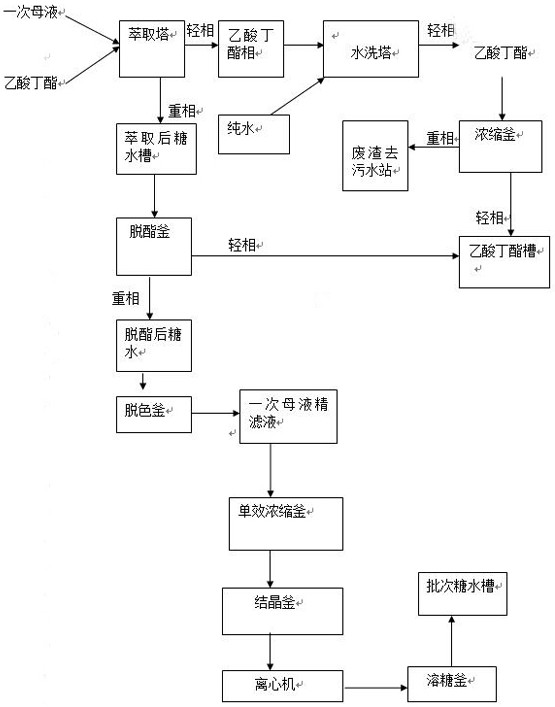

[0021] (1) Pump the primary mother liquor (sugar water concentration 28%, acetic acid content 480PPM) from the drying section into the upper part of the extraction tower at 2000L / h, pump butyl acetate from the bottom of the extraction tower at 1000L / h, and the primary mother liquor Carry out counter-current extraction with butyl acetate in the extraction tower, and the butyl acetate phase coming out from the top of the tower after extraction enters the water washing tower at 1000L / h;

[0022] (2) Add pure water to the water washing tower at 600L / h for washing. The washed butyl acetate enters the concentration tank for concentration, and the temperature in the concentration tank is controlled at 45°C. The concentrated butyl acetate phase enters the butyl acetate tank and The phase (waste residue) goes to the sewage station, and the heavy phase after washing goes to the waste water degreasing kettle, and after removing butyl acetate in the water, it is sent to the thickening and ...

Embodiment 2

[0026] (1) Pump the primary mother liquor (sugar water concentration 29%, acetic acid content 500PPM) from the drying section into the upper part of the extraction tower at 2000L / h, pump butyl acetate from the bottom of the extraction tower at 1000L / h, and the primary mother liquor Carry out counter-current extraction with butyl acetate in the extraction tower, and the butyl acetate phase coming out from the top of the tower after extraction enters the water washing tower at 800L / h;

[0027] (2) Add pure water to the water washing tower at 500L / h for washing. The washed butyl acetate enters the concentration tank for concentration, and the temperature in the concentration tank is controlled at 48°C. The concentrated butyl acetate phase enters the butyl acetate tank and The phase (waste residue) goes to the sewage station, and the heavy phase after washing goes to the waste water degreasing kettle, and after removing butyl acetate in the water, it is sent to the thickening and d...

Embodiment 3

[0031] (1) Pump the primary mother liquor (concentration of sugar water 30% and acetic acid content of 520PPM) from the drying section into the upper part of the extraction tower at 2000L / h, pump butyl acetate from the bottom of the extraction tower at 1100L / h, and the primary mother liquor Carry out counter-current extraction with butyl acetate in the extraction tower, and the butyl acetate phase coming out from the top of the tower after extraction enters the water washing tower at 900L / h;

[0032] (2) Add pure water to the water washing tower at 550L / h for washing, and the washed butyl acetate enters the concentration tank to concentrate, control the temperature in the concentration tank to 42°C, the concentrated butyl acetate phase enters the butyl acetate tank, and The phase (waste residue) goes to the sewage station, and the heavy phase after washing goes to the waste water degreasing kettle, and after removing butyl acetate in the water, it is sent to the thickening and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com