Stone sewage precipitation system

A sewage and stone technology, applied in sedimentation treatment, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of affecting sedimentation, difficult treatment, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

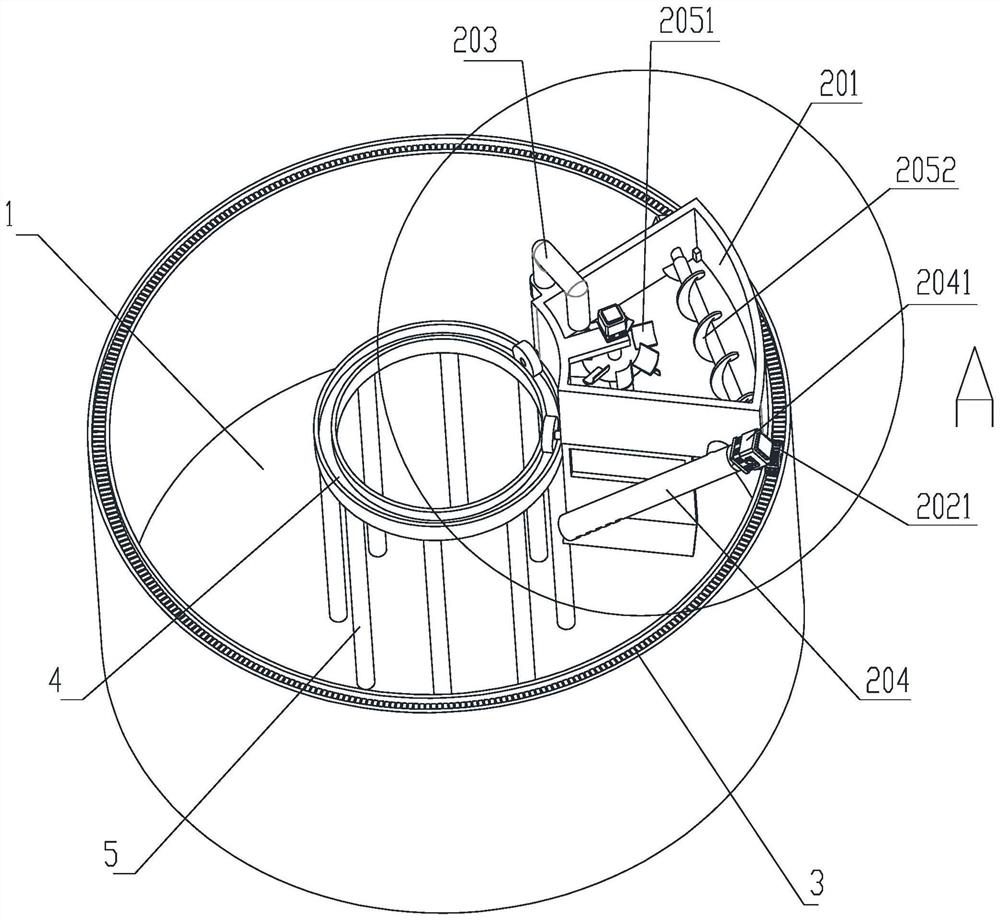

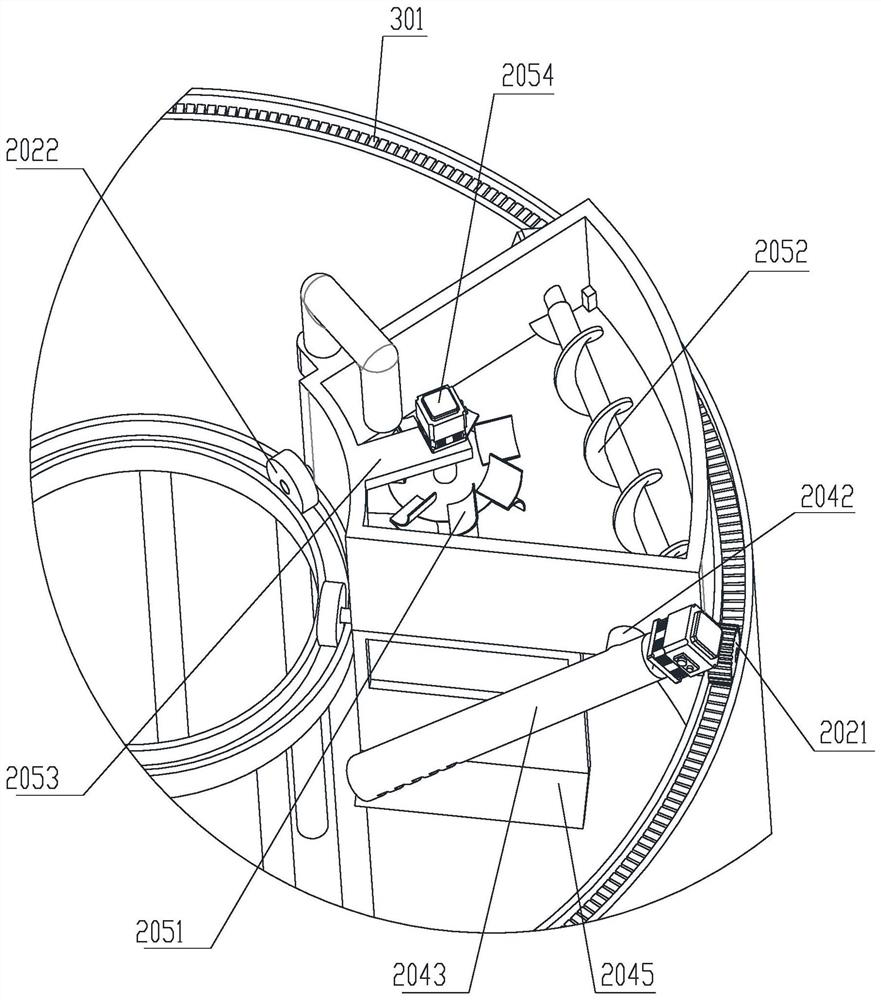

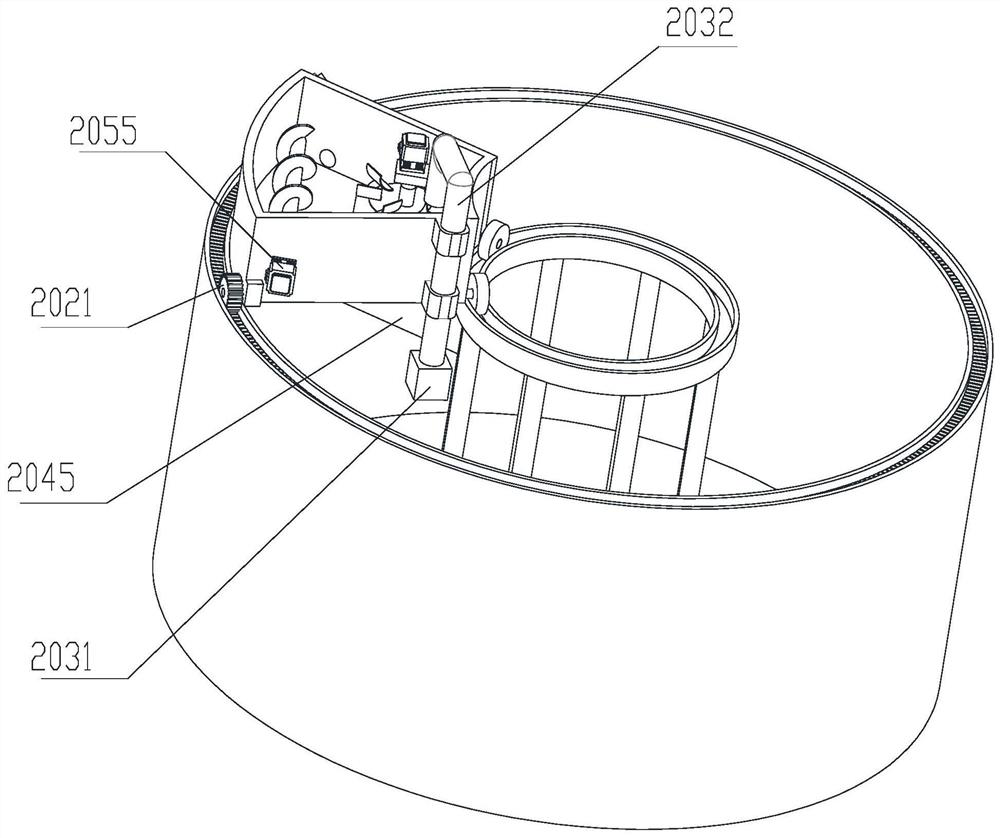

[0028] see Figure 1 to Figure 4 , the present invention provides a stone sewage sedimentation system, comprising a sedimentation tank 1, a track is arranged on the top of the sedimentation tank 1, a stirring box for walking is arranged on the track, the mixing box includes a stirring box 201, and a walking mechanism, one side of the stirring box 201 is provided with a water inlet mechanism 203, the other side of the stirring box 201 is provided with a feeding mechanism 204, and the inside of the stirring box 201 is provided with a stirring mechanism;

[0029] The sedimentation tank 1 is an annular tank body; the track includes an outer track 3 and an inner track 4 that are sheathed from outside to inside; one side of the stirring box 201 is provided with an arc-shaped inner wall corresponding to the inner track 4, and the other side of the stirring box 201 is set There is an arc-shaped outer wall corresponding to the outer track 3; a water inlet stirring blade 2051 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com