Machining method for stepped ring grooves of supercharger sliding bearing

A technology of sliding bearings and processing methods, which is applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve the problems of affecting processing efficiency, insufficient tool rigidity, large margin of fillet parts, etc. The effect of low cost and small milling allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

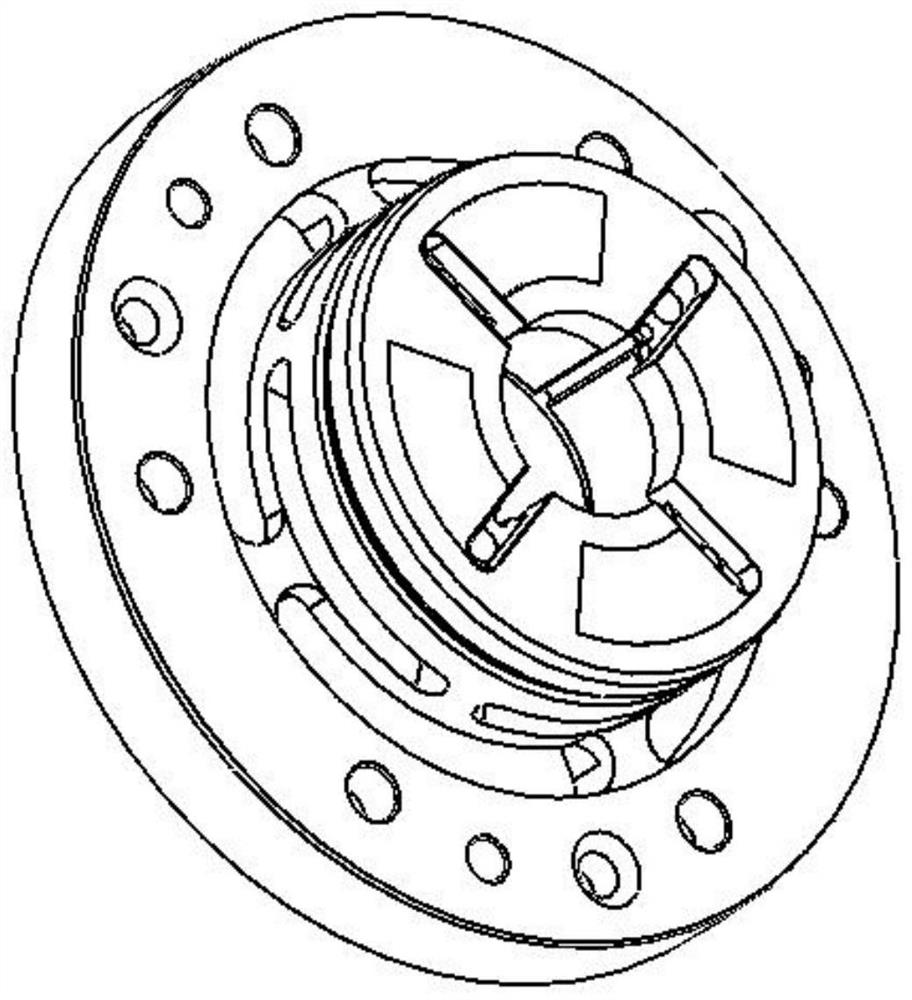

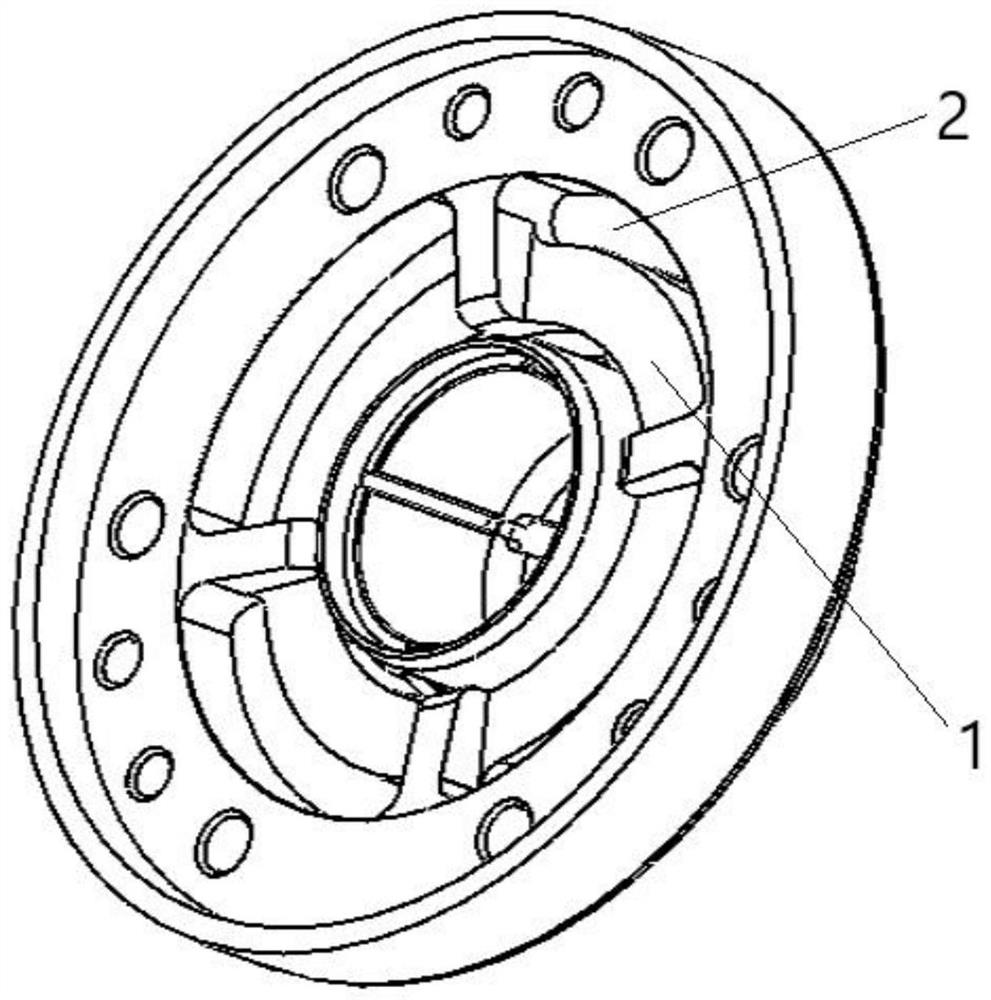

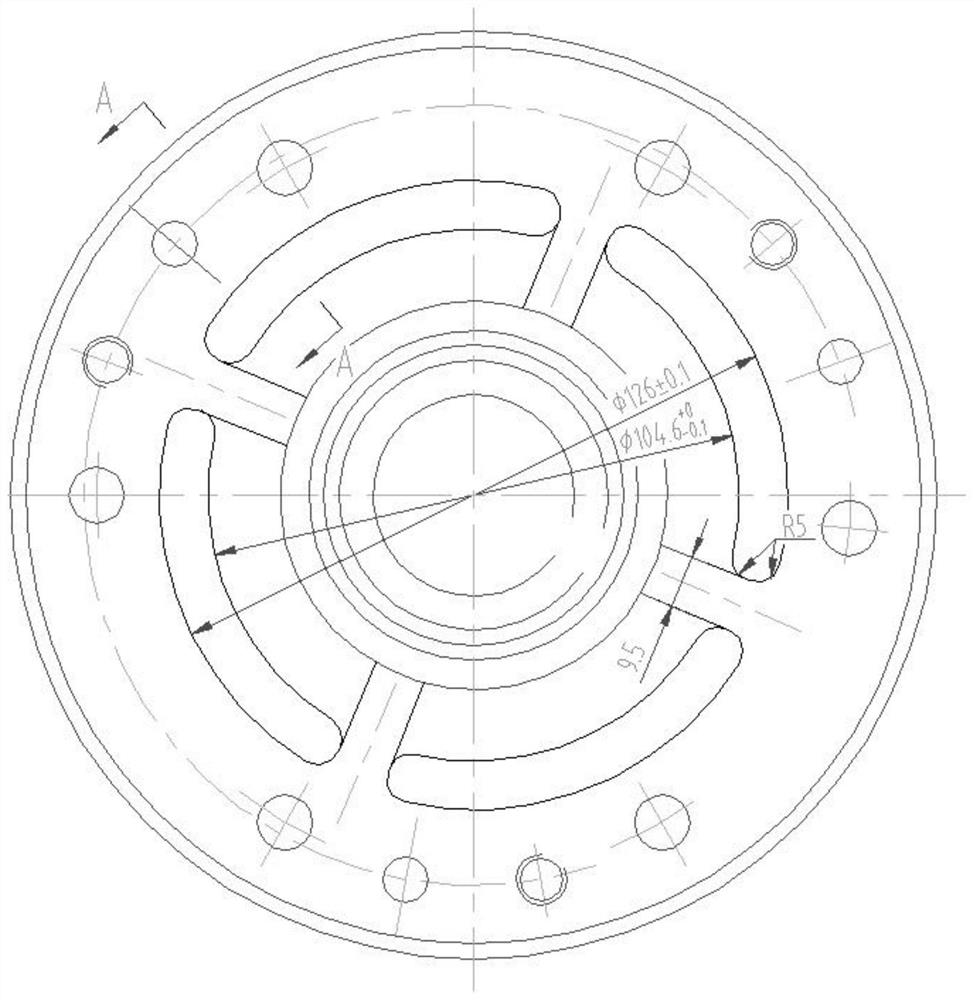

[0024] see Figure 4-Figure 6 , a method for processing stepped ring grooves of supercharger sliding bearings. First of all, in terms of processing methods, this patent application changes the original method of mainly milling, and uses drilling and milling combined processing to remove the remaining corners as much as possible. Quantity, using the combined roughing scheme of D10 and D16 end mills to improve processing efficiency,

[0025] Include the following steps:

[0026] S1. Prepare the supercharger sliding bearing. The supercharger sliding bearing is to be processed with four stepped ring grooves evenly arranged in the circumferential direction. The stepped ring groove is fan-shaped as a whole, including the upper ring groove and communicating with the outer side of the upper ring groove the lower ring groove;

[0027] S2. Drill holes at the center of the circle to be rounded at both ends of each stepped ring groove, and reserve a finishing allowance for subsequent ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com