A processing equipment for paper tube automatic claw picking

A technology of processing equipment and automatic claws, which is applied in the direction of metal processing equipment, metal processing, drilling/drilling equipment, etc., can solve the problems of low processing accuracy and low processing efficiency, achieve precise processing accuracy, improve processing efficiency, and avoid The effect of manual loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

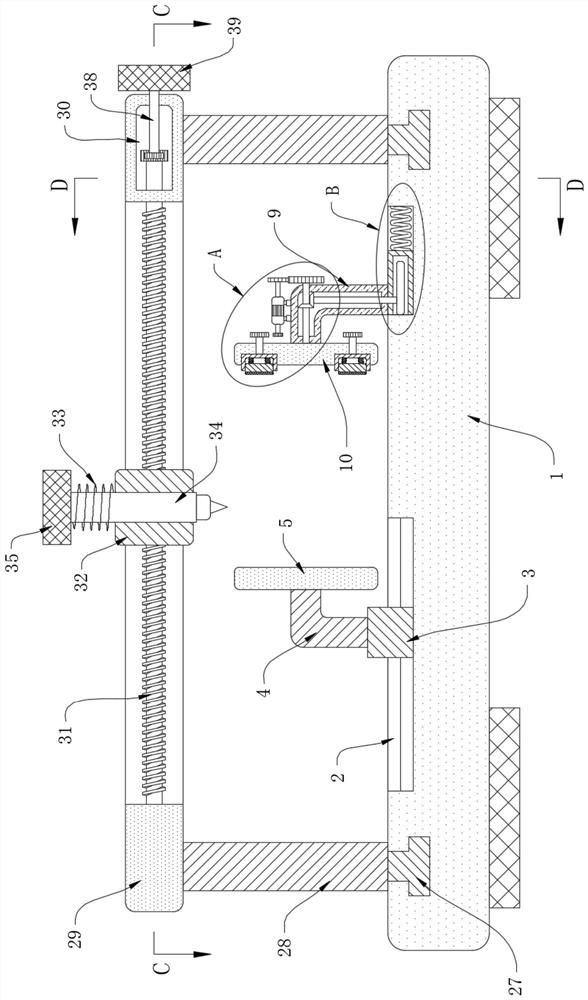

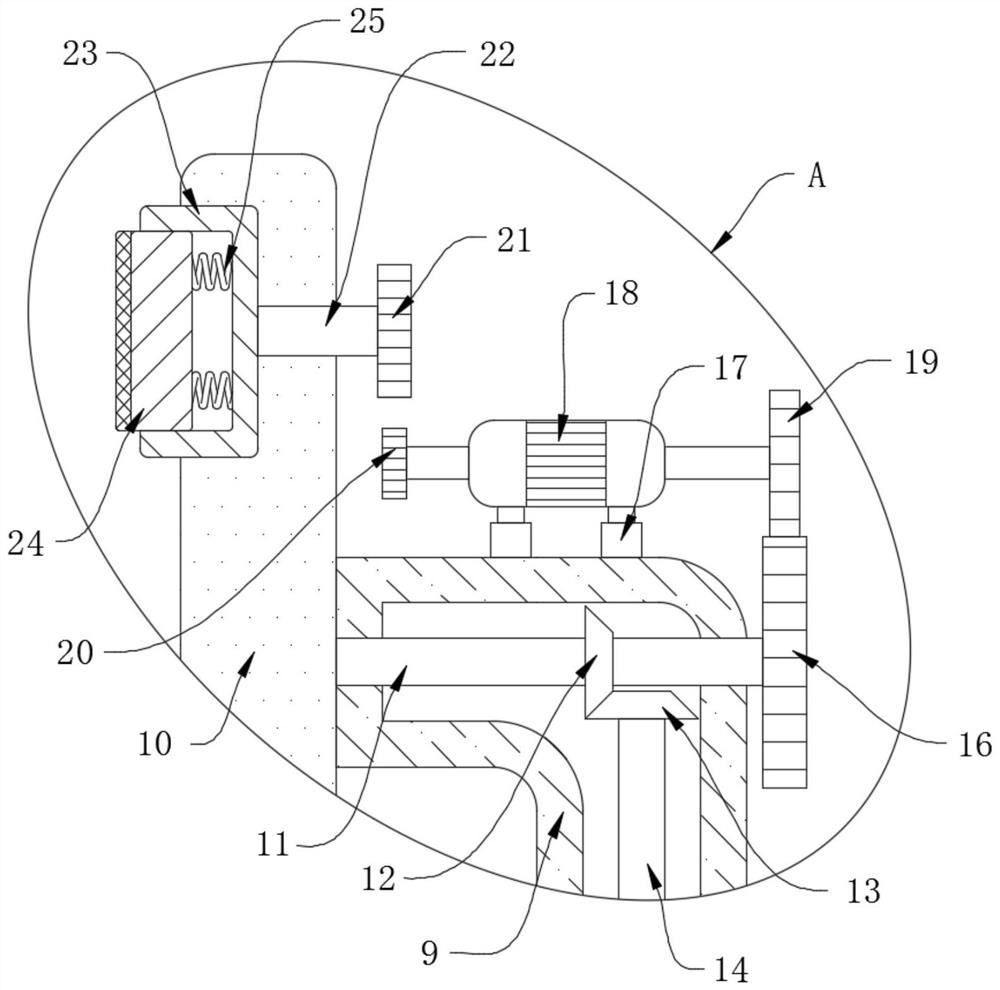

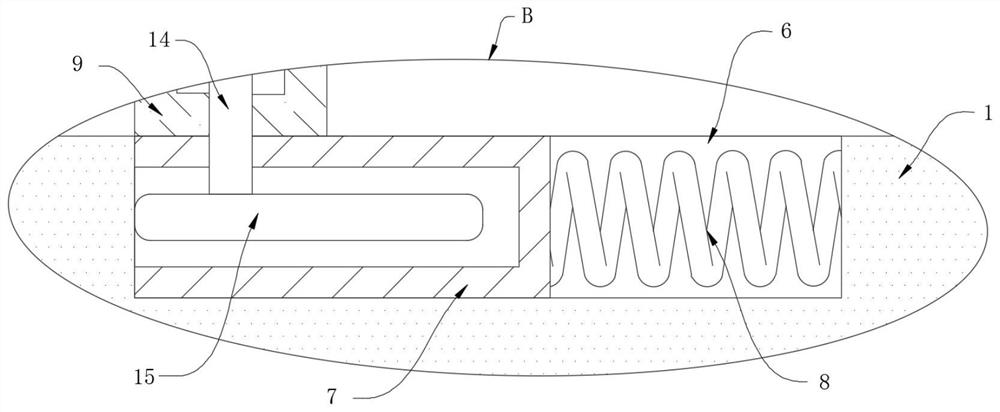

[0030] refer to Figure 1-6 , a kind of processing equipment for paper tube automatic claw and hand, comprising an operation table 1 and a conveyor belt 101, a square steel pipe to be processed is placed on the conveyor belt 101, and a length adjustment block 3 is slidably connected to the upper surface of the operation table 1 through a length adjustment groove 2, The upper surface of the console 1 is slidably connected with a moving block 7 through the functional groove 6. The functional groove 6 is a T-shaped groove, and the moving block 7 is a T-shaped slider. Spring 8, the cross-section of moving block 7 is the concave shape of opening downward side, length adjusting block 3, the upper surface of moving block 7 are respectively welded with first supporting block 4, the second supporting block 9, the first supporting block 4 and the second supporting block The two support blocks 9 are all L-shaped structures, the second support block 9 is a hollow structure, and the side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com