Remotely-controlled lead-acid battery carrying truss robot

A truss robot, lead-acid battery technology, applied in lead-acid battery, lead-acid battery construction, conveyor control device and other directions, can solve the problems of difficult manufacturing, high labor input, short service life, etc. The effect of avoiding equipment failure and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

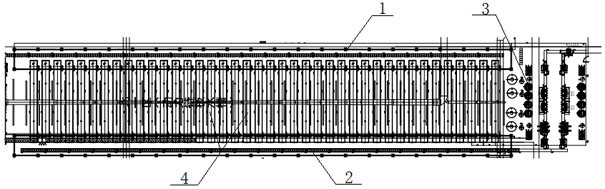

[0073] refer to Figure 1 to Figure 10 , the embodiment of the present invention provides a remote-controlled lead-acid battery transport truss robot, the truss robot transports the lead-acid battery filled with acid to the entrance of the water tank 4, the bottom of the water tank 4 is provided with a conveyor belt, and the conveyor belt transports the The lead-acid battery is delivered to the inside of the tank 4; the truss robot includes: the truss robot 1 entering the tank and the truss robot 2 leaving the tank;

[0074] The tank-entry truss robot 1 and the tank-out truss robot 2 are symmetrically distributed at both ends of the tank;

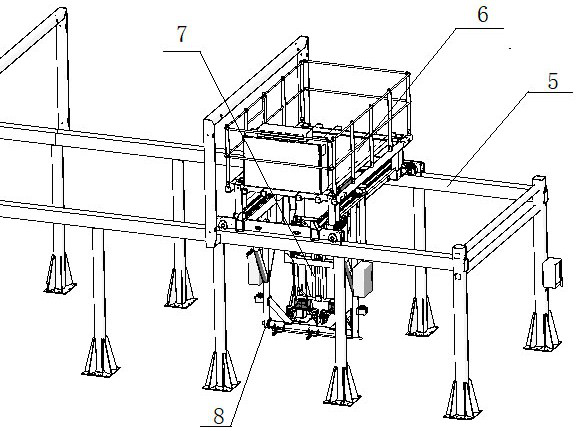

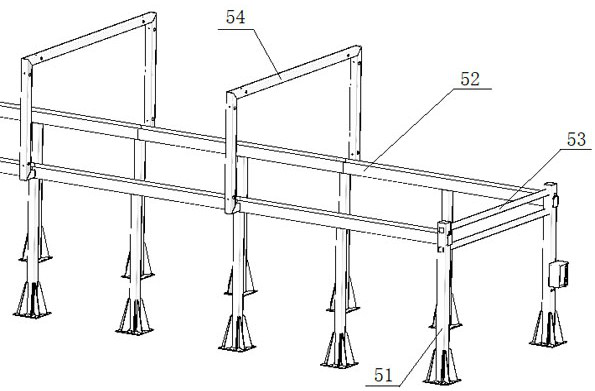

[0075] The tank truss robot 1 and the tank truss robot 2 include an X-axis guide rail truss 5, a robot body 6 and a batte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The maximum length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com