Particle screening device for raw material processing

A technology for sieving particles and raw materials, which is applied in the field of sieving devices for raw material processing, can solve problems such as low screening efficiency, and achieve the effects of promoting screening efficiency, promoting screening and avoiding stacking blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

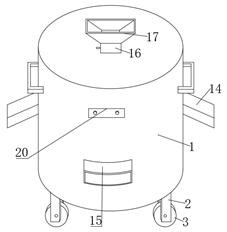

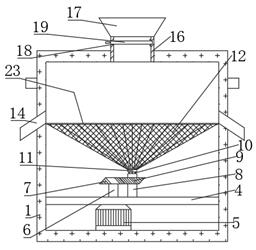

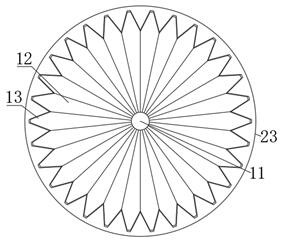

[0030] refer to Figure 1-3 , a sieving device for raw material processing, comprising a box body 1, a plurality of legs 2 fixed by bolts at the bottom of the box body 1, rollers 3 fixed on the bottom of the legs 2 by bolts, a control switch 20 fixed by bolts at the front end of the box body 1, The inner wall of the box body 1 is fixed with a partition 4 by bolts, and the bottom of the partition 4 is fixed with a motor 5 by bolts. The output shaft of the motor 5 runs through the partition 4 and is connected with a first straight shaft 6. The complete bevel gear 7, the top of the partition plate 4 is connected with the second straight shaft 8 by hinge rotation, the second straight shaft 8 is sleeved and fixed with the complete bevel gear 9, the incomplete bevel gear 7 and the complete bevel gear 9 are meshed and connected, the second The top of the straight shaft 8 is fixed with a plurality of pillars 10 by bolts, the top of the plurality of pillars 10 is fixed with the same fi...

Embodiment 2

[0034] refer to Figure 1-2 and Figure 4-7 , a sieving device for raw material processing, the inner wall of the feeding part 13 is rotatably connected with a plurality of bulk material rods 21 through bearings, the cross section of the bulk material rods 21 is arranged in a Y shape, and the plurality of bulk material rods 21 are distributed in a serpentine shape, and scattered The material rods 21 are of different sizes, and a plurality of bulk material wires 22 are fixed between a plurality of bulk material rods 21. The feeding part 24 is arranged between two adjacent feeding parts 13, and the discharging part 24 is arranged in a shape that is wide first and then narrowed from the inside to the outside, and the inner wall of the feeding part 13 is provided with a plurality of raised parts 25, The protruding part 25 and the screen plate 12 are integrally structured, the protruding part 25 is arranged as a spherical structure with different curvatures, and the top of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com