A processing system and process of soybean meal for feed

A processing system and feed technology, applied in the field of processing system of soybean meal for feed, can solve the problem of inability to dry powder, achieve the effects of ensuring drying effect, simple and reasonable system structure, and reducing energy consumption of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

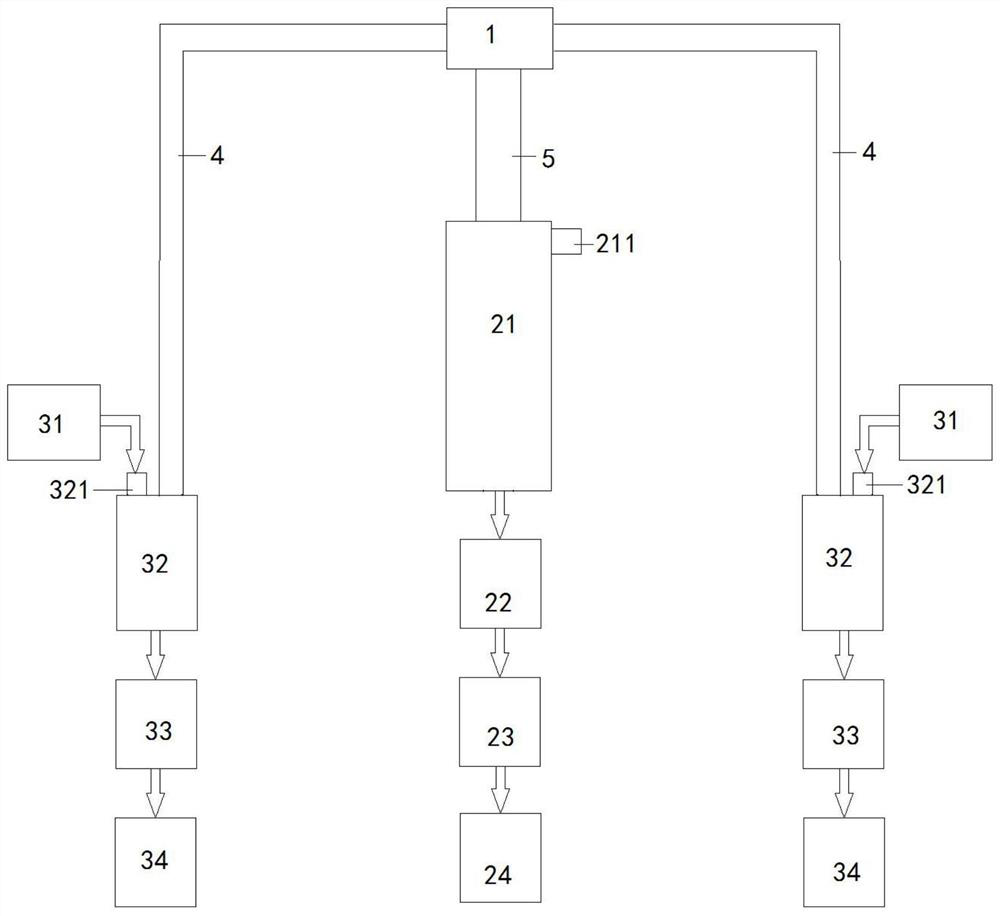

[0026] Such as figure 1 As shown, this embodiment provides a processing system for soybean meal for feed, including a hot blast stove 1, a monolithic processing line and two powder processing lines; Dryer 21, first pulverizer 22, first screening machine 23 and first drying mechanism 24, that is, the whole material processing line first puts the same batch of raw materials with high moisture content into the first drum type feed drying machine 21 for drying, and after drying, it is discharged into the first pulverizer 22 for pulverization; the powder processing line includes a second pulverizer 31, a second drum feed dryer 32, a second The screening machine 33 and the second drying mechanism 34, that is, the powder processing line, first put the same batch of raw materials with a lower moisture content into the second pulverizer 31 for pulverization, and then dry the powder; A drum type feed dryer 21 and a second drum type feed dryer 32 are connected in parallel to the same ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com